Internal tension type isolation door

An isolation door and tensioning technology, applied in the direction of sealing device, etc., can solve the problems that threaten the normal operation and maintenance personnel of the coal mill, the door body is not closed tightly, and the door plate is worn, etc., to achieve ingenious structure, improve safety, and improve The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

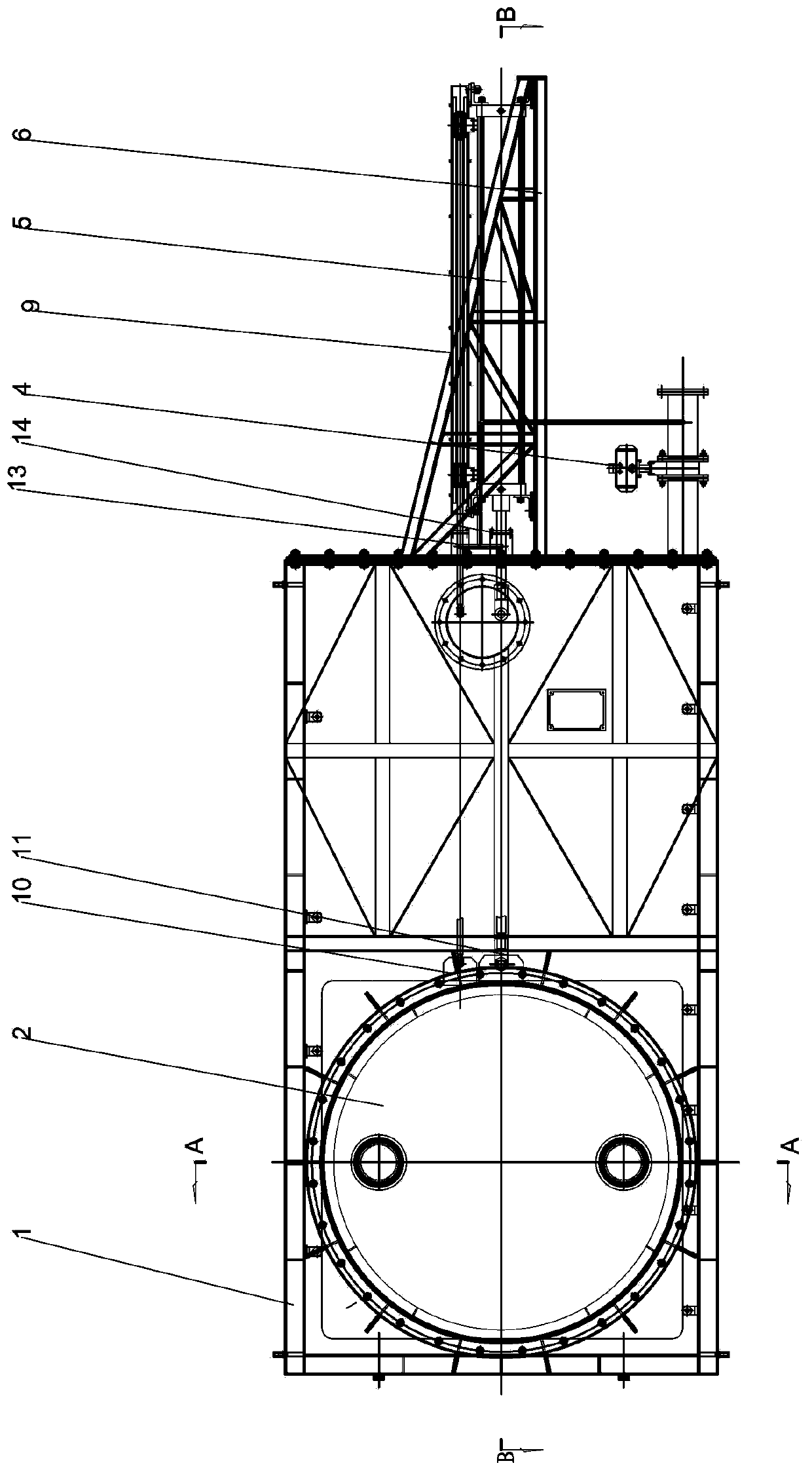

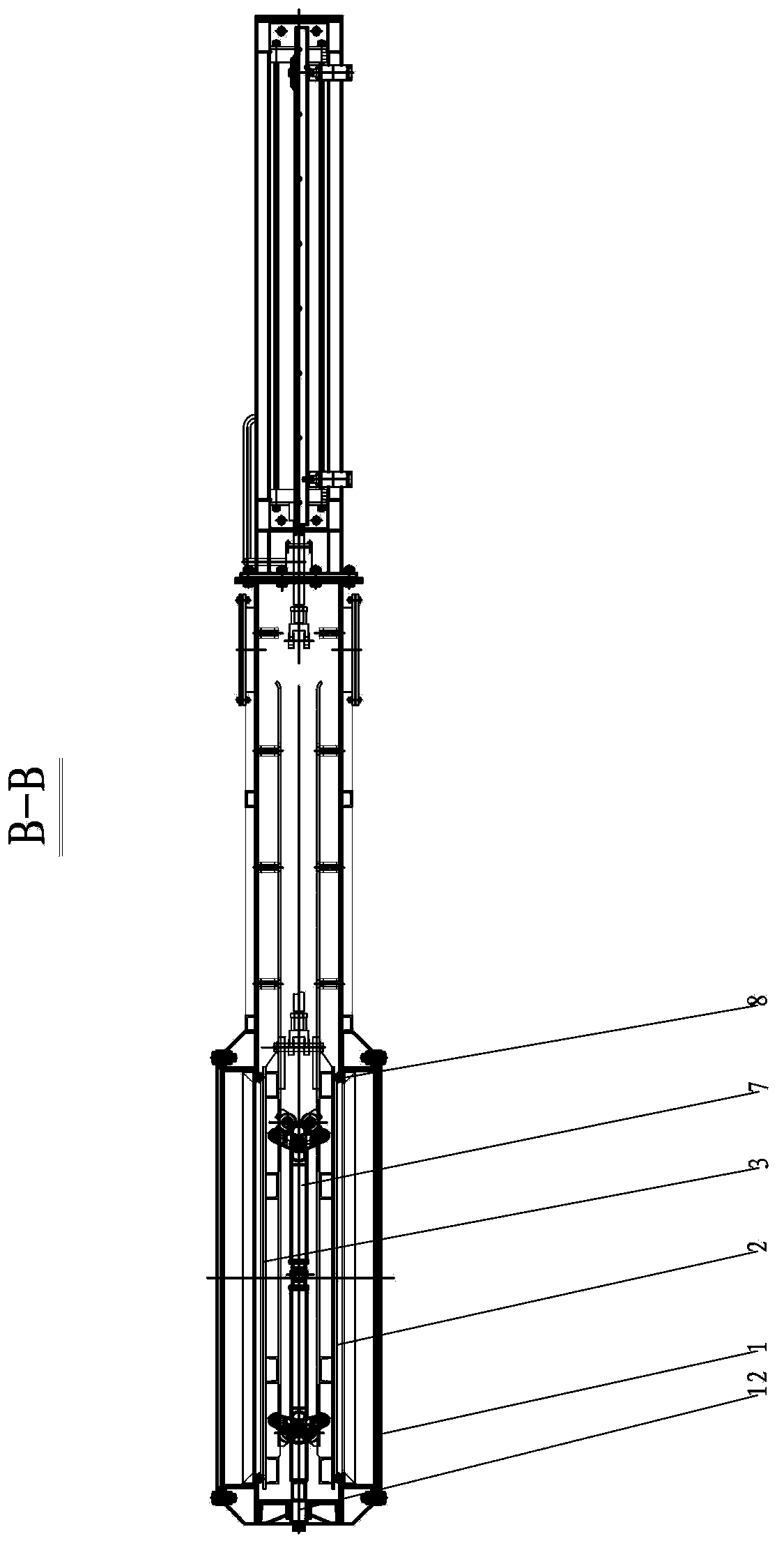

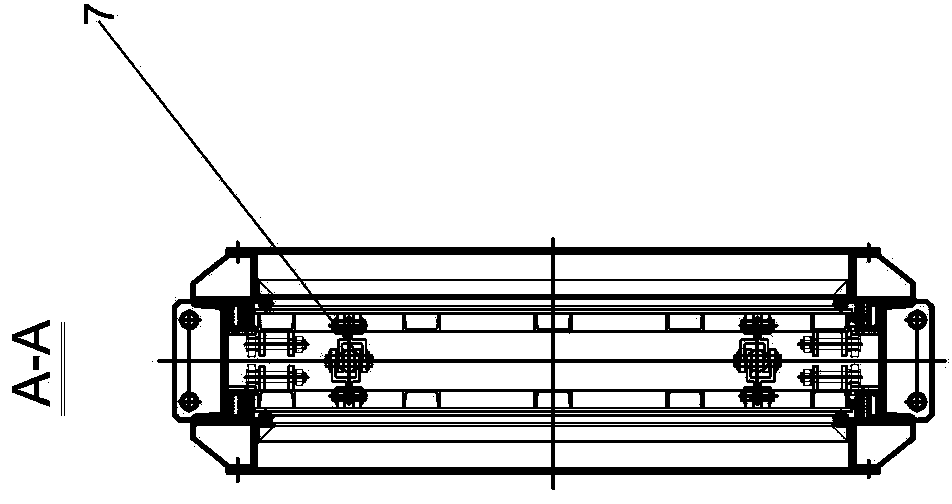

[0031] like Figure 1~3 As shown, the present invention mainly comprises a door frame 1, a first door panel 2, a second door panel 3, a sealing wind device 4, a drive cylinder 5 and a locking mechanism 7, and the door frame 1 is provided with a first door panel 2 and a second door panel parallel to each other. 3. A sealing ring 8 is provided between the door frame 1 and the first door panel 2 and the second door panel 3 . The lower part of the door frame 1 side is fixed with a sealing wind device 4, and the middle part of the side of the door frame 1 is fixed with a push-pull rod sealing support 13 and a piston rod sealing support 14. The sides of the first door panel 2 and the second door panel 3 are jointly connected with push-pull rod lugs 10 and piston rod lugs 11 . The middle part of the door frame 1 side is fixed to drive the cylinder support 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com