Bidirectional push-pull type hot air isolating door

A hot air isolation door, two-way push-pull technology, applied to door/window accessories, wing leaf arrangement, wing leaf parts, etc., can solve the problems of door panels not being tightly closed, leakage, increased frictional resistance, etc., to reduce maintenance and The failure rate, flexible and reliable opening, and the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

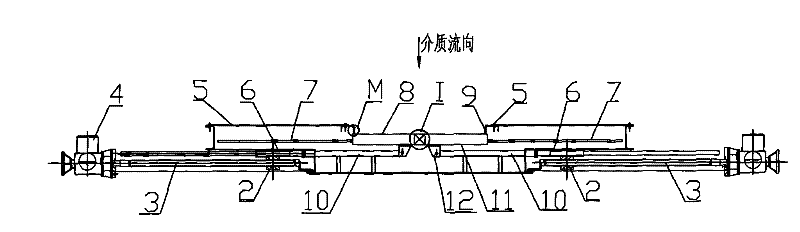

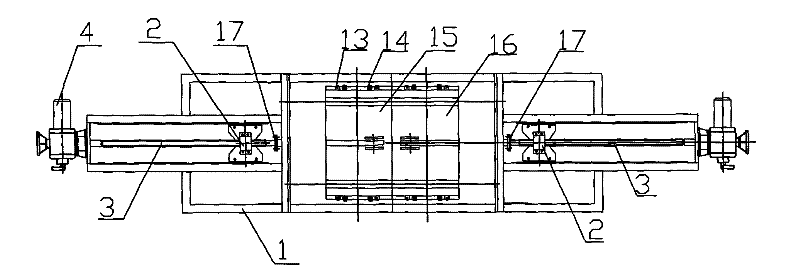

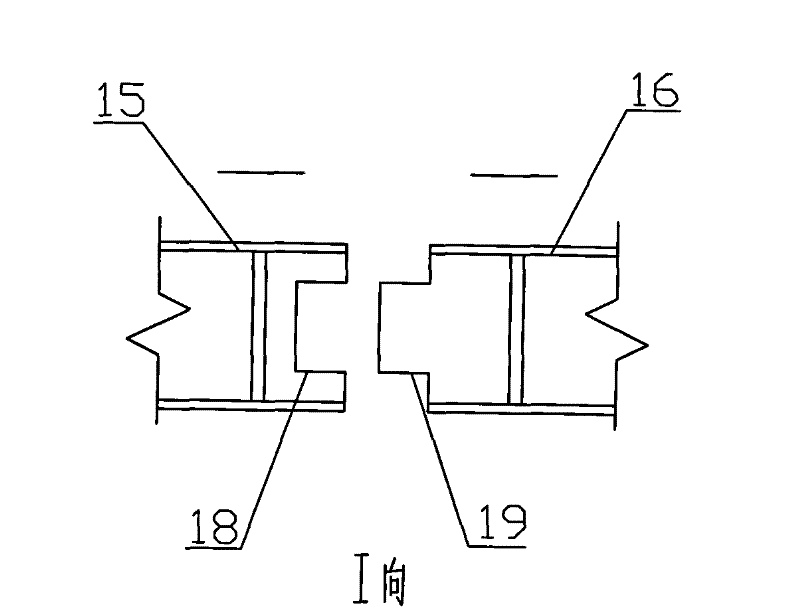

[0015] Such as Figure 1 to Figure 4 As shown, it includes door frame 1, transmission nut body 2, transmission screw 3, electric actuator 4 (pneumatic actuator is also acceptable), inspection hole cover 5, push-pull rod support 6, guide rail 7, door panel sealing surface 8, hard Sealing device 9, push-pull rod 10, door panel away from the sealing surface side 11, push-pull rod seat 12, load-bearing wheel 13, guide wheel 14, first door panel 15, second door panel 16, push-pull rod disc change box 17 concave surface 18, convex Shape surface 19, flat sheet 20, corner sheet 21, pressing plate 22 and sealing side plate 23 etc.

[0016] In the present invention, the first door panel 15 and the second door panel 16 are movable parts of the isolation door, and are placed in the door frame 1 . A set of driving devices are respectively installed symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com