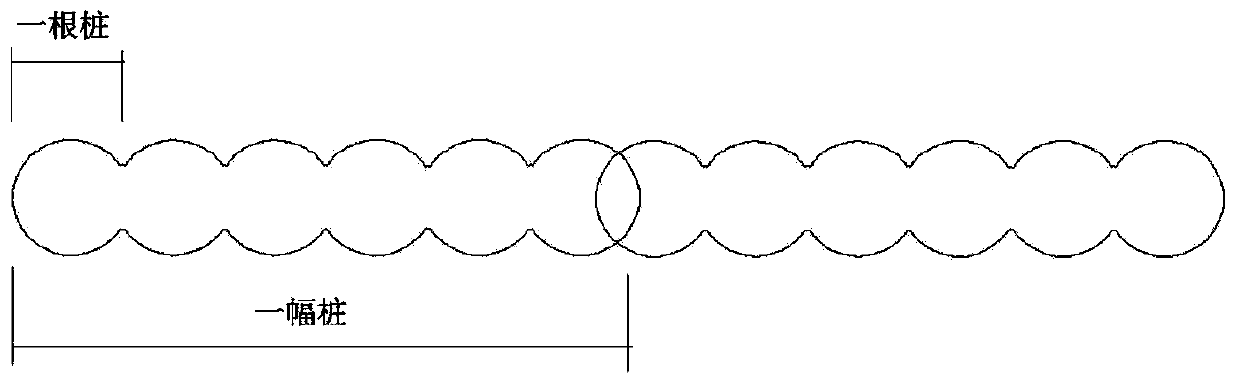

Six-shaft cement mixing pile machine

A cement-soil mixing pile and six-axis technology, which is applied to sheet pile walls, earthwork drilling, drilling equipment, etc., can solve the problems of small number of cement-soil mixing piles, high cost, and high cost, so as to improve construction quality and reduce equipment The effect of simple construction cost and equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] Example 2, see Figure 6 , the drill rod passes through the power box and extends upwards, the height of the pile frame does not need to be higher than the drill rod, so that the ultra-long drill rod can be drilled smoothly. All the other simultaneous embodiment 1.

Embodiment 3

[0052] Embodiment 3, see Figure 7, the drill rod is connected with the agitating drill bit 11 at the same height at the bottom of the drill rod, and the agitating drill bit 11 does not interfere with each other before starting to rotate, so when all the drill rods rotate synchronously at a uniform speed, they do not interfere with each other. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com