Orbit tool changer based on grooved wheel mechanism

A technology of a sheave mechanism and a changer, which is applied in the direction of tools, manufacturing tools, manipulators, etc., can solve the problems of a track tool changer such as large mass, affecting the reliability of space operation, and complex structure, and achieves compact structure, high reliability, The effect of large pose tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

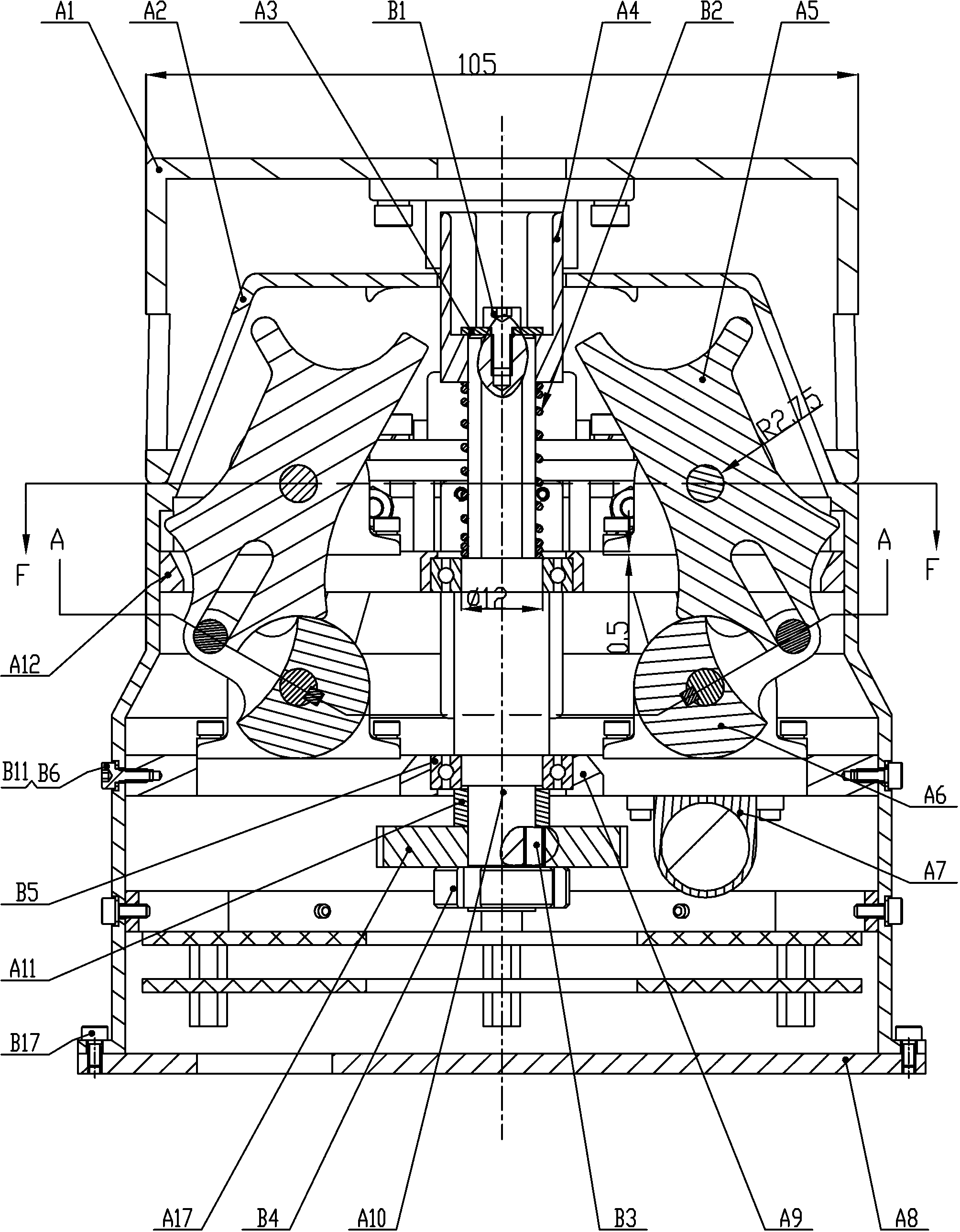

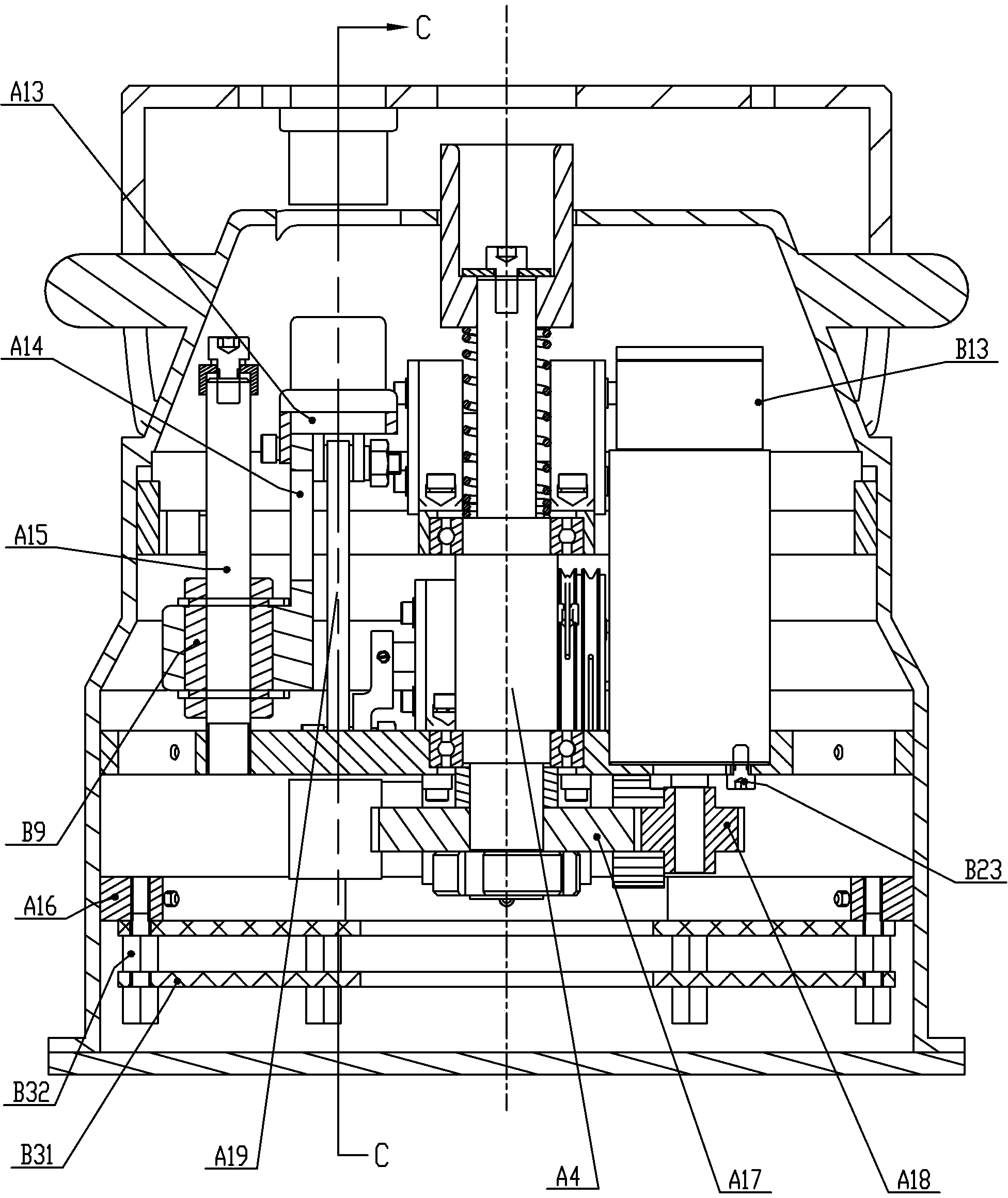

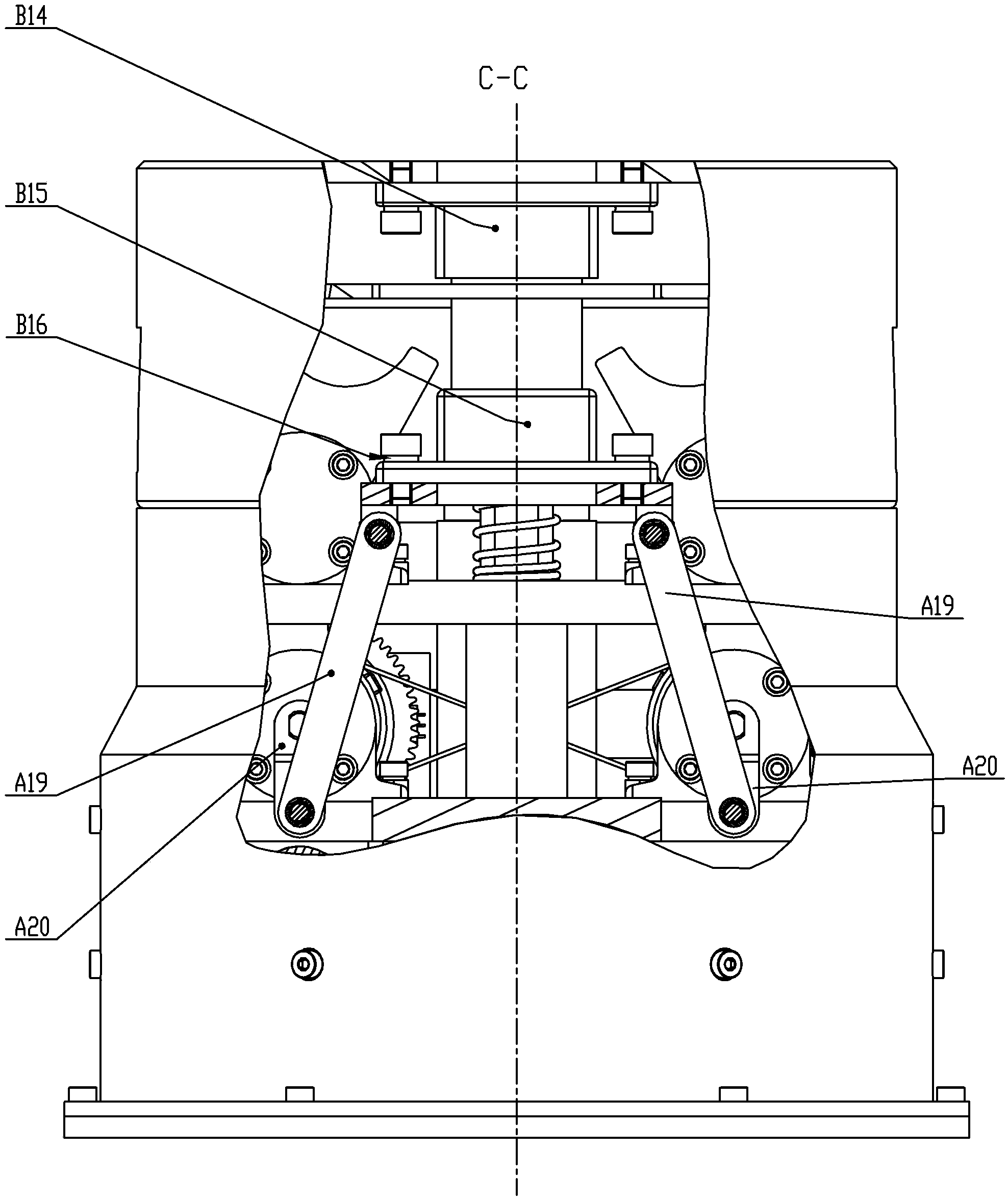

[0024] Specific implementation mode one: as Figures 1 to 8 As shown, the track tool changer based on the sheave mechanism of this embodiment includes a tool end interface A1, a housing A2, a bottom end cover A8, a lower support ring A9, an upper support ring A12, a circuit board support frame A16, and an electrical system 1. The first drive system and the second drive system, the upper support ring A12, the lower support ring A9, and the circuit board support frame A16 are installed in the housing A2 from top to bottom, the electrical system, the first drive system and the second drive system The two sets of driving systems are placed in the housing A2, the electrical system is placed on the circuit board support frame A16, the lower end surface of the housing A2 is connected to the bottom end cover A8; the tool end interface A1 is set on the housing A2;

[0025] The first set of drive system (to realize mechanical transmission) includes a first input device, a first transmis...

specific Embodiment approach 2

[0029] Specific implementation mode two: as Figures 1 to 8 As shown, the dial A6 in this embodiment is in the shape of a cam, and the dial pin A27 installed on the dial A6 moves linearly in the groove opened by the driven sheave A5. When the tool end interface is A1, the dial pin A27 breaks away from the linear groove of the sheave A5, so that the dial A6 can rotate idly, so as to realize the docking of the electrical connector interface. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: as Figures 1 to 8 As shown, the limit switch of the second set of drive system in this embodiment adopts a Hall sensor, and the Hall sensor B29 is glued to the support block A23 above the bearing seat, and the magnetic steel is embedded in the long axis gear of the dial On A22, the second drive system uses potentiometer B33 for absolute position sensing. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com