Linear seven-axis transfer robot for stamping

A technology for handling robots and straight lines, which is applied in the field of seven-axis straight lines. It can solve problems such as heavy weight, difficulty in fast and efficient handling, and insufficient compact structure of the seven-axis body, and achieve the effects of light weight, shortened production efficiency, and simplified handling tracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical solutions of the present invention, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

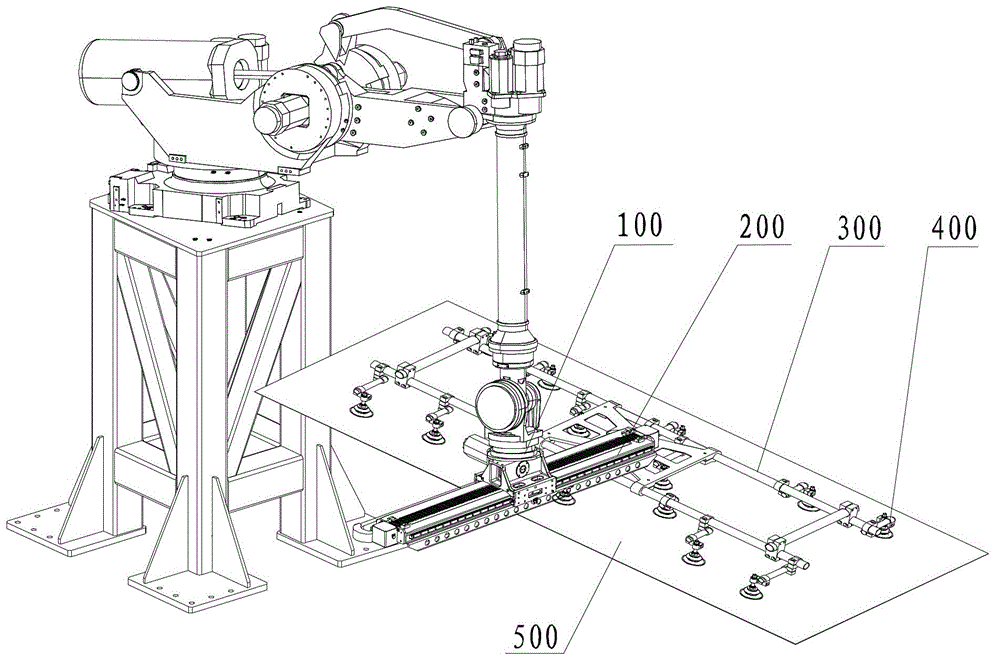

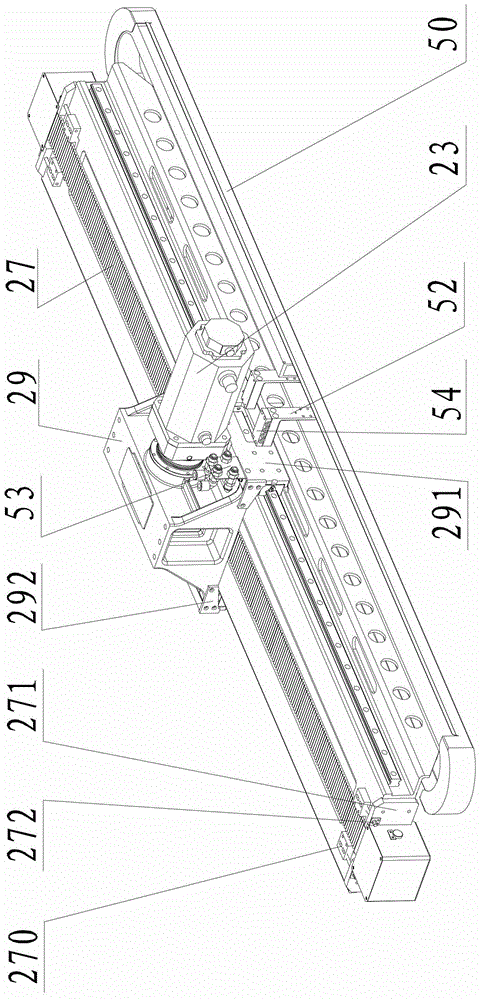

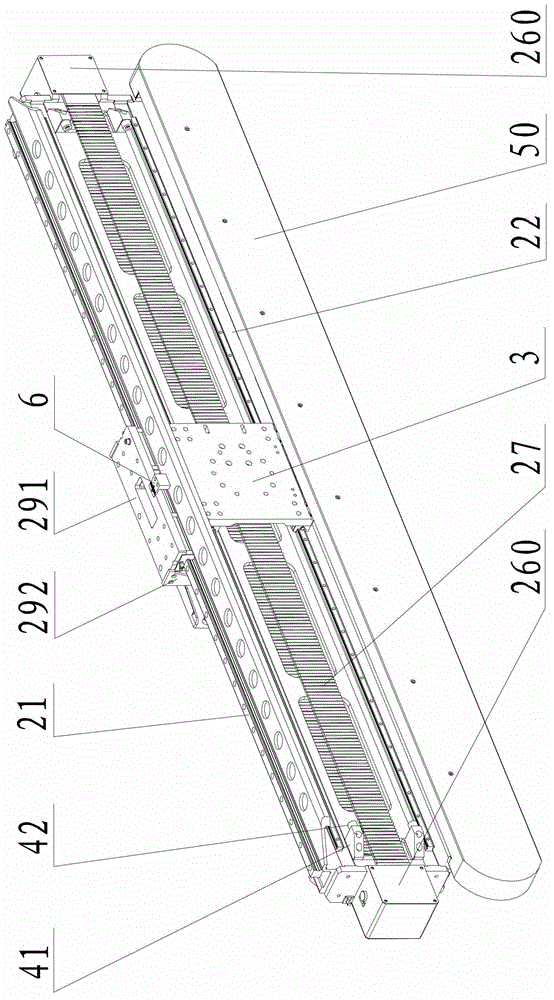

[0028] see Figure 1 to Figure 9 , the straight line seven-axis 200 of the handling robot for stamping of the present invention is connected between the sixth axis end flange 100 of the robot and the end picker 300, and the straight line seven-axis 200 includes a main arm 1, a straight line moving device, One end pickup mounting plate 3, four sets of buffer mechanisms and a drag chain device.

[0029] Main arm 1 (see Figure 8 and Figure 9 ) is extruded from aviation aluminum, the main arm 1 includes a main arm main body 10 with a rectangular frame in cross section and front and rear supports respectively connected to the front and rear sides of the lower end of the main arm main body 10 and forming a transverse U shape Plates 11, 12; in order to enhance the rigidity of the main arm 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com