Lathe fast moving device

A lathe and drive shaft technology, applied in feeding devices, metal processing machinery parts, metal processing and other directions, can solve the problems of labor and time, and achieve the effect of reducing ineffective labor, saving time and labor, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

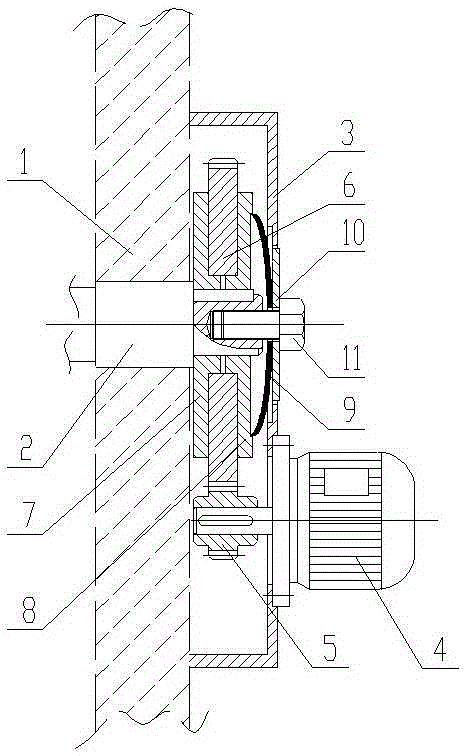

[0020] see figure 1 , a lathe fast-moving device according to the present invention, which includes a slide box 1 and a transmission shaft 2, the slide box 1 is arranged on the drive shaft 2, and the front side of the slide box 1 is provided with a gear box shell Body 3, the lower part of the gearbox housing 3 is provided with a motor 4, the output end of the motor 4 is provided with a pinion 5 through a key, and the front end of the transmission shaft 2 is provided with a fixed friction plate 7 and a moving friction plate 8 through a key, so The moving friction plate 8 is located in front of the fixed friction plate 7, and a large gear 6 is arranged between the fixed friction plate 7 and the moving friction plate 8, and the pinion 5 and the large gear 6 are located in the gearbox housing 3 and mesh with each other. A pressing plate 10 is arranged in front of the transmission shaft 2 , a butterfly spring 9 is arranged between the pressing plate 10 and the dynamic friction plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com