Threaded screening machine

A screening machine and screw thread technology, which is applied in the field of workpiece detection and screening devices, can solve the problems of high labor intensity, unqualified products mixed into qualified products, and slow screening speed, and achieve the effect of low labor intensity, high production efficiency and fast screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

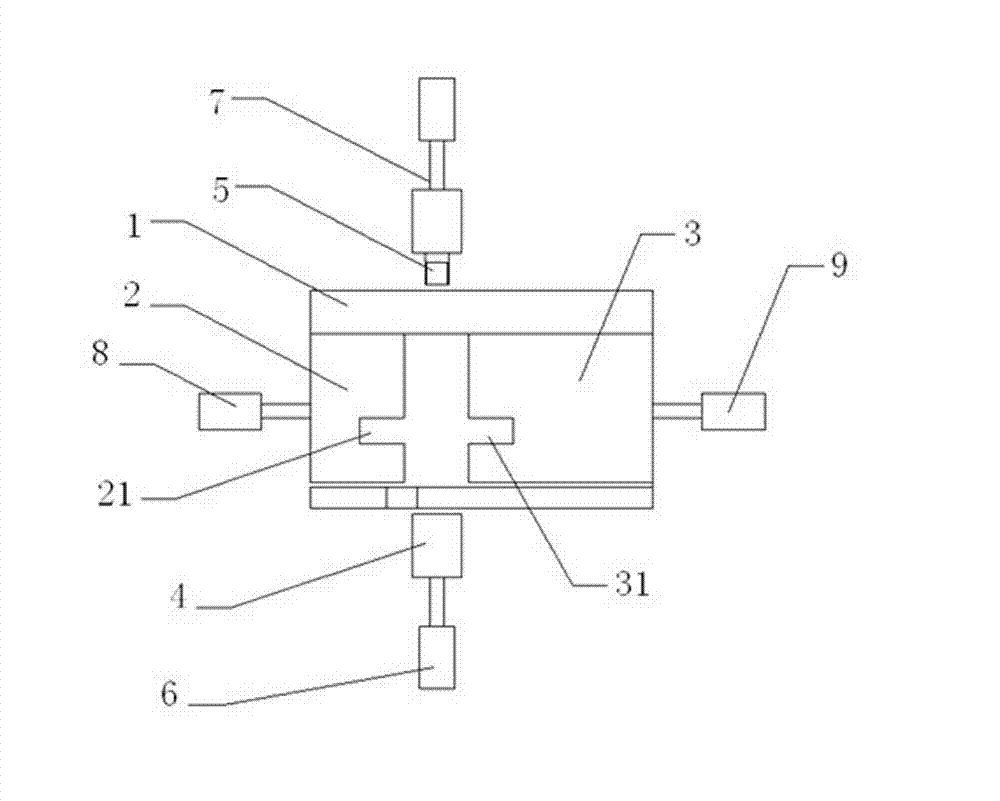

[0008] Embodiment: a thread screening machine, including frame 1, first and second positioning blocks 2, 3, feeder, top block 4, tooth gauge 5, first, second, third, and fourth power devices 6, 7, 8 , 9 and the controller, the first and second positioning blocks 2 and 3 can be slid and positioned on the frame 1, and the opposite side walls of the first and second positioning blocks are respectively provided with a number of first and second positioning blocks with symmetrical structures and vertically arranged Two inner grooves 21, 31, the first and second inner grooves 21, 31 are matched with the outer wall of the nut circumference, the discharge port of the feeder is located directly above the middle position of the first and second positioning blocks 2, 3, and the top block 4 and tooth gauge 5 are located on the axial sides of a pair of first and second inner grooves 21 and 31 respectively, and the combined top block 4, tooth gauge 5 and the pair of first and second inner gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com