Mechanical device converting clutch type reciprocating translational motion into continuous rotary motion in same direction

A mechanical device and co-rotating technology, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of not making full use of the inertia of transmission parts, difficulty in installation, easy slipping and price, and achieve compact structure, Fewer conversion links and less transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

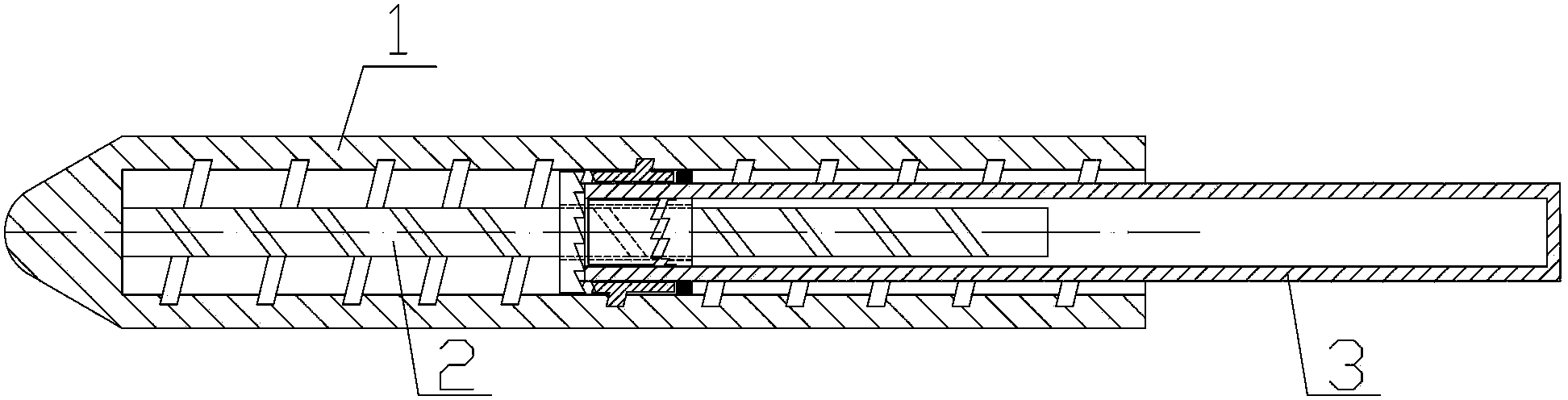

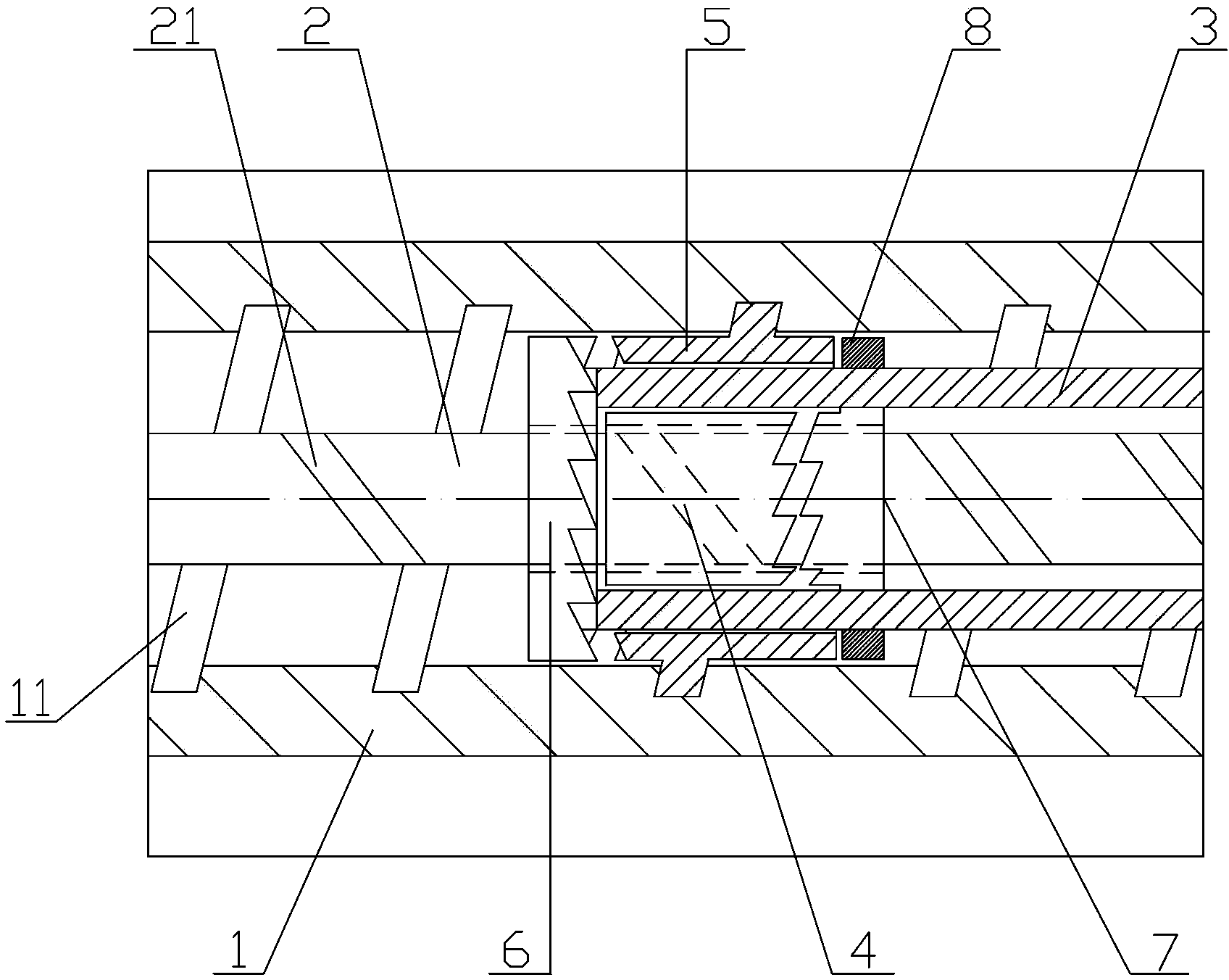

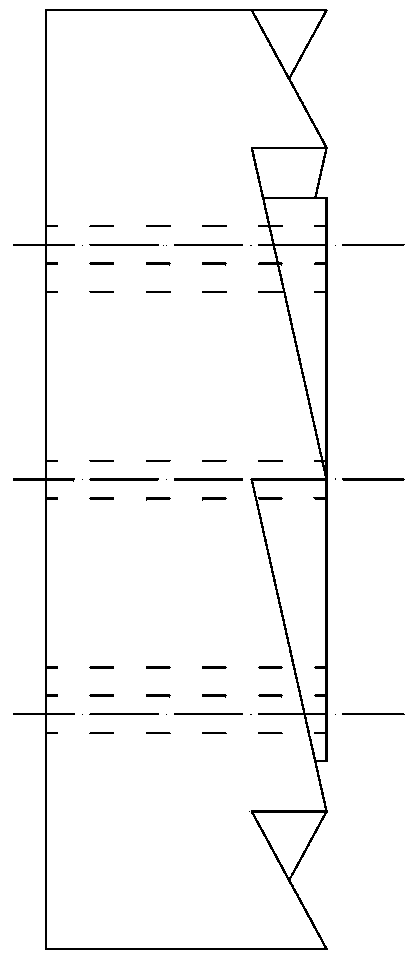

[0034] Such as figure 1 and figure 2 As shown, this embodiment discloses a mechanical device that converts clutch-type reciprocating translational motion into continuous co-rotational motion. The device includes an external thread screw 1, an internal thread screw 2, a rotating sleeve 3, and an internal rotating slider 4. Outer rotary slide block 5, port closing ring 6, inner meshing ring 7, outer limiting ring 8. The internally threaded screw 2 is installed inside the externally threaded screw 1 and arranged coaxially with the externally threaded screw 1 . The left end of the externally threaded lead screw 1 is closed and used for connecting the driving device, and the right end is open and used for connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com