Manual and precision plunger pressuring pump

A booster pump and plunger technology, which is applied in the field of manual plunger precision booster pumps, can solve the problems of poor pressure regulation accuracy, low pressure resistance, and low resolution of pressure regulation, and achieve a smooth and no fluctuation in the pressure regulation process , The pressurized driving torque is small, and the effect of high pressure regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

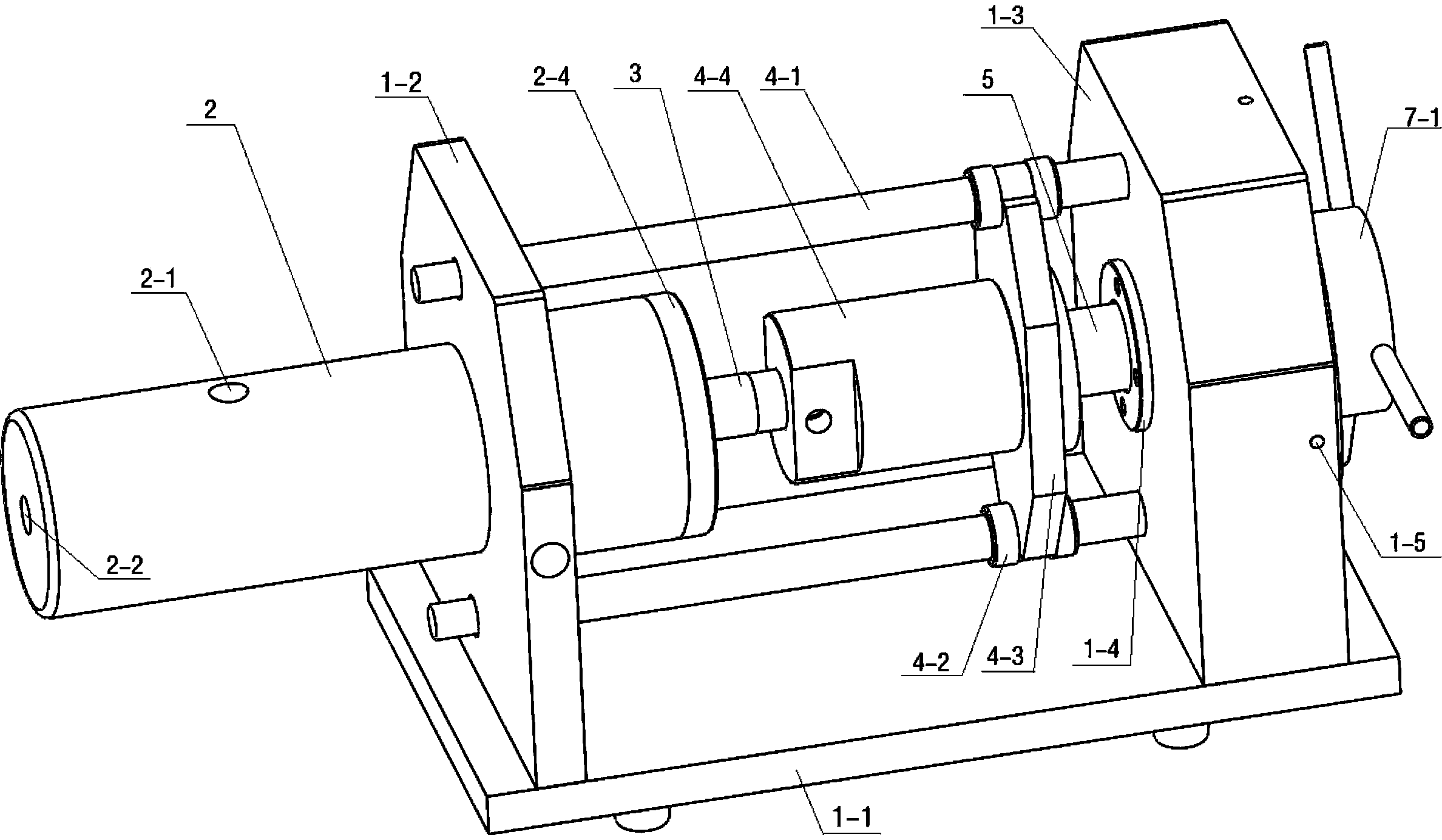

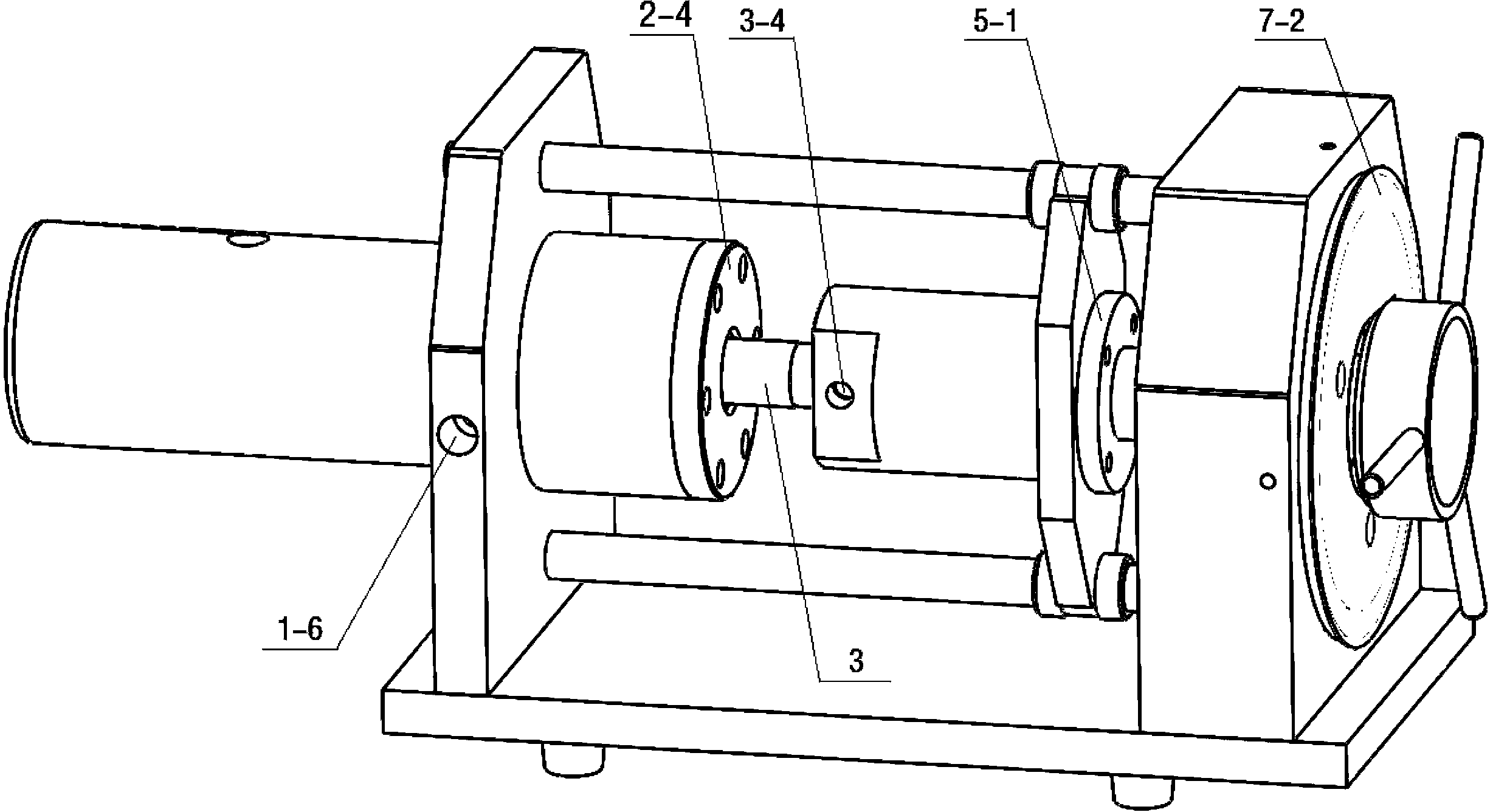

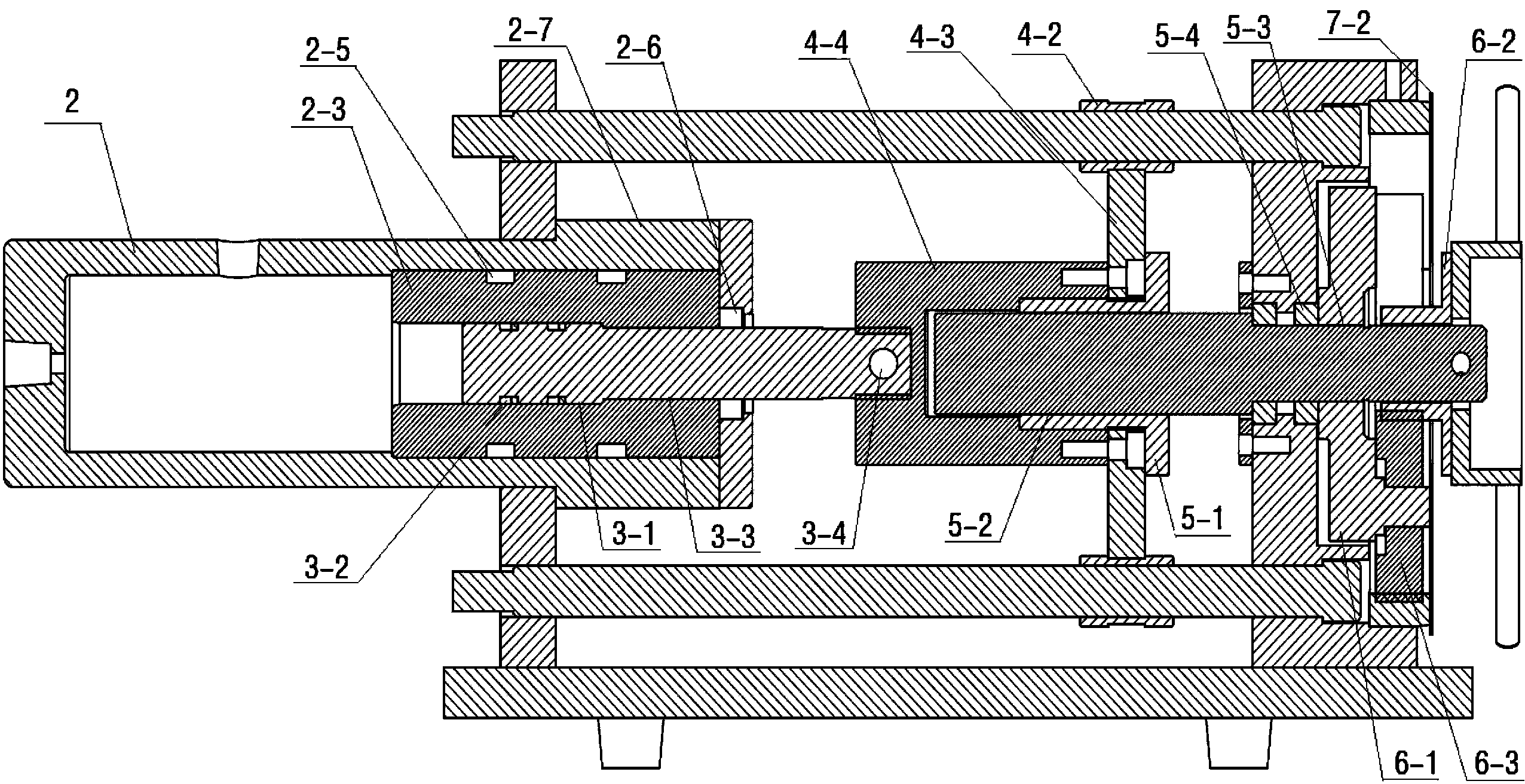

[0023] Combine Figure 1 ~ Figure 7 For manual plunger precision pressurizing pumps, the design basis is based on the theory of the effective volume modulus of oil. To explain the theory of the effective volume modulus of oil, the effective volume modulus of oil must be defined first. e as follows:

[0024] K e = ΔP × V - ΔV

[0025] Effective bulk modulus of elasticity for oil K e The explanation of is helpful to the understanding of the theory of the effective bulk elastic modulus of oil. Any elastic modulus can be explained by stress and strain. For the bulk elastic modulus of oil, the stress refers to the pressure of the oil, and the strain refers to the oil. The rate of change of liquid volume. The compressibility of liquid refers to the nature of the volume reduction of oil under pressure. When the pressure is P, the corresponding volume of the pressure oil is V. When the pressure increases by ΔP, the volume decreases by ΔV. The manual plunger prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com