Repairable vibration-reducing track system of prefabricated steel spring floating plates

A technology of floating slabs and prefabricated slabs, which is applied to tracks, roads, ballast layers, etc., can solve problems that affect the normal operation of trains, difficult quality control, and difficult maintenance, and achieve superior vibration and noise reduction performance and construction The effect of fast speed, simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

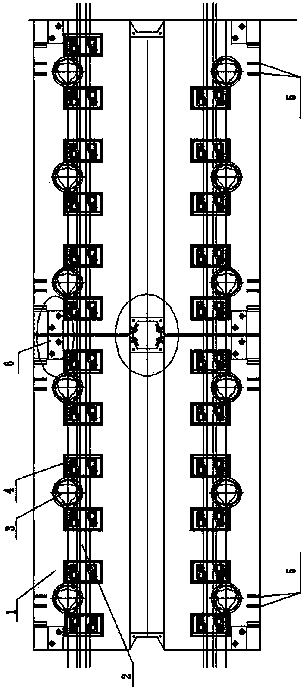

[0022] Such as figure 1 The repairable prefabricated steel spring floating slab damping track system shown in the figure has a floating slab length of 3730mm, a slab width of 2700mm, and a gutter width of 400mm.

[0023] There are 3 vibration isolators under one prefabricated slab and one rail, and a prefabricated slab with a vibration isolator arranged every 2 fasteners (referred to as 22 layout), that is, 3 vibration isolators on the left and right sides of a prefabricated slab, a total of 6 isolators vibrator. The ends of the adjacent floating slabs are connected with the vertical and vertical two-way fixed connectors of the foundation under the railway track and the vertical and horizontal two-way fixed connectors of the foundation under the railway track. The observation tube is arranged at the horizontal and vertical two-way fixed connectors of the railway under the rails of the two floating slabs. There is a gap of 20mm between the two plates, and lifting sleeves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com