Well flushing fluid for relieving damage of drilling fluid in low permeability sandstone gas layer and preparation method thereof

A technology of drilling fluid and flushing fluid, which is applied to the flushing fluid and its preparation to relieve the damage of drilling fluid in low-permeability sandstone gas layers. In the field of ancient low-permeability sandstone reservoirs in Changqing, it can solve the problem of severe damage and reduce damage. , improve efficiency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The following components are used to prepare the flushing fluid for removing the damage caused by the drilling fluid of the ancient low-permeability sandstone gas layer in Changqing. According to the weight percentage, the weight ratio of surfactant is 0.05-0.1%, the weight ratio of chloroform as organic solvent is 8-10%, and formic acid The weight ratio of potassium is 5.0-6.0%, the weight ratio of hydrogen peroxide is 0.5-0.8%, the weight ratio of hydrofluoric acid is 0.5%-0.8%, and the balance is water. It is mixed to make the well flushing that relieves the damage of drilling fluid in the ancient low-permeability sandstone gas layer of Changqing liquid.

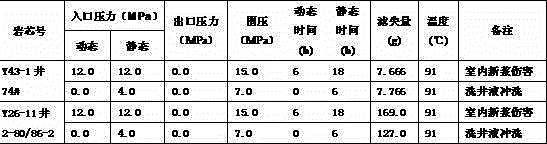

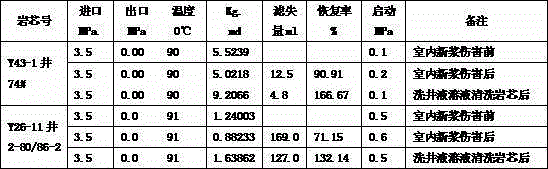

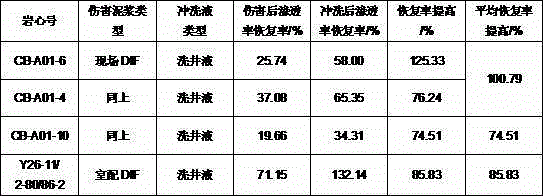

[0022] 1. Experimental Evaluation of Well Flushing Fluid for Improving Recovery Value of Gas Permeability After Injury in Example 1

[0023] According to the natural gas industry standard of the People's Republic of China "SY / T6540-2002 Indoor Evaluation Method for Drilling Fluid and Completion Fluid Damage to Rese...

Embodiment 2

[0039] The following components are used to prepare the flushing fluid for removing the damage caused by the drilling fluid in the ancient low-permeability sandstone gas layer in Changqing, using 85.6% by weight of clean water, 0.1% by weight of surfactant, and 8% by weight of chloroform as an organic solvent , Potassium formate 5.0% by weight, hydrogen peroxide 0.7% by weight, and hydrofluoric acid 0.6% by weight, mixed to make a well flushing fluid for removing damage from drilling fluids in Changqing ancient low-permeability sandstone gas reservoirs.

Embodiment 3

[0041] The following components are used to prepare the flushing fluid for removing the damage caused by the drilling fluid in the ancient low-permeability sandstone gas layer in Changqing, using 82.6% by weight of clean water, 0.1% by weight of surfactant, and 10% by weight of chloroform as an organic solvent , 6.0% by weight of potassium formate, 0.8% by weight of hydrogen peroxide, and 0.5% by weight of hydrofluoric acid, mixed to make a well-washing fluid for removing damage from drilling fluids in Changqing ancient low-permeability sandstone gas reservoirs.

[0042] In the application of Examples 2 and 3, the well flushing fluid system also exhibits the obvious improvement of the recovery rate of the permeability, the ability to overcome the water locking effect, and the simple and easy formulation and mixing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com