Method for extracting natural bioactive protein from unpolished rice or/and rice bran

A technology for biologically active proteins and salt-soluble proteins is applied in the field of extracting natural biologically active proteins, which can solve the problems of complex and uncertain components, insufficient cleanliness, complicated processes, etc., and achieves good economic and environmental benefits, low preparation cost, The effect of inhibiting lipid peroxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

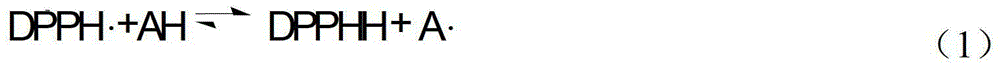

Method used

Image

Examples

Embodiment 1

[0028] 1) The commercially available Beidahuang Lvye organic brown rice from Beidahuang Green Food Distribution Co., Ltd. was used as the raw material, which was crushed and passed through a 40-mesh sieve to obtain the rice flour raw material. Acetone was used to degrease the rice flour raw material. The rice flour raw material (g) was mixed with acetone ( mL) Solid-to-liquid ratio 1:3g / mL, shake for 2 hours, centrifuge at 6000rpm for 20 minutes to collect the precipitate, and place it in a fume hood to dry naturally to obtain defatted rice noodles.

[0029] 2) Extraction of total salt-soluble protein from rice: Weigh 15g of defatted rice flour and add 120mL of 1.0mol / L NaCl aqueous solution. supernatant to obtain a total salt-soluble protein solution;

[0030] 3) Ethanol precipitation to remove impurities: add absolute ethanol to the total salt-soluble protein solution in step 2), the volume ratio of the total salt-soluble protein solution to absolute ethanol is 1:2, and stir...

Embodiment 2

[0033] 1) The commercially available Beidahuang Green Field organic brown rice from Beidahuang Green Food Distribution Co., Ltd. was used as the raw material, which was crushed and passed through a 50-mesh sieve to obtain the rice flour raw material. Acetone was used to degrease the rice flour raw material. The rice flour raw material (g) was mixed with acetone ( mL) solid-to-liquid ratio 1:3g / mL, after shaking for 2h, centrifuge at 6000rpm for 20min to collect the precipitate, and place it in a fume hood to dry naturally to obtain defatted rice noodles;

[0034] 2) Extraction of total salt-soluble protein from rice: Weigh 15g of defatted rice flour and add 150mL of 1.0mol / L NaCl aqueous solution, mix well, shake and extract at 30°C for 2h, centrifuge at 6000rpm for 20min to collect the supernatant, repeat step 2) once, and combine the supernatant solution to obtain the total salt-soluble protein solution;

[0035] 3) Ethanol precipitation to remove impurities: add absolute et...

Embodiment 3

[0038] 1) Use commercially available fine defatted rice bran powder produced by Jiangxi Tianyu Oil Co., Ltd. as raw material, as defatted rice flour;

[0039] 2) Extraction of total rice salt-soluble protein: Accurately weigh 15g defatted rice flour and add 1.0mol / L NaCl aqueous solution 150mL, mix well, shake and extract at 30°C for 2h, centrifuge at 6000rpm for 20min to collect the supernatant, repeat step 2) once, combine supernatant to obtain a total salt-soluble protein solution;

[0040] 3) Ethanol precipitation to remove impurities: add absolute ethanol to the total salt-soluble protein solution in step 2), the volume ratio of the total salt-soluble protein solution to absolute ethanol is 1:2.5, and stir and mix with a magnetic stirrer at the same time, place Precipitate at 4°C for 1 hour, centrifuge at 8000rpm for 20 minutes, remove the precipitated part, collect the supernatant to obtain the biologically active protein solution;

[0041] 4) Post-treatment, ethanol re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com