AO reactor for water treatment

A reactor and water treatment technology, applied in the field of AO reactors for water treatment, can solve the problems of inability to excrete wastes in time, inconvenient processing, transportation and installation, and unsatisfactory service life, and achieve easy mass production, The effect of good water quality and low cost after treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

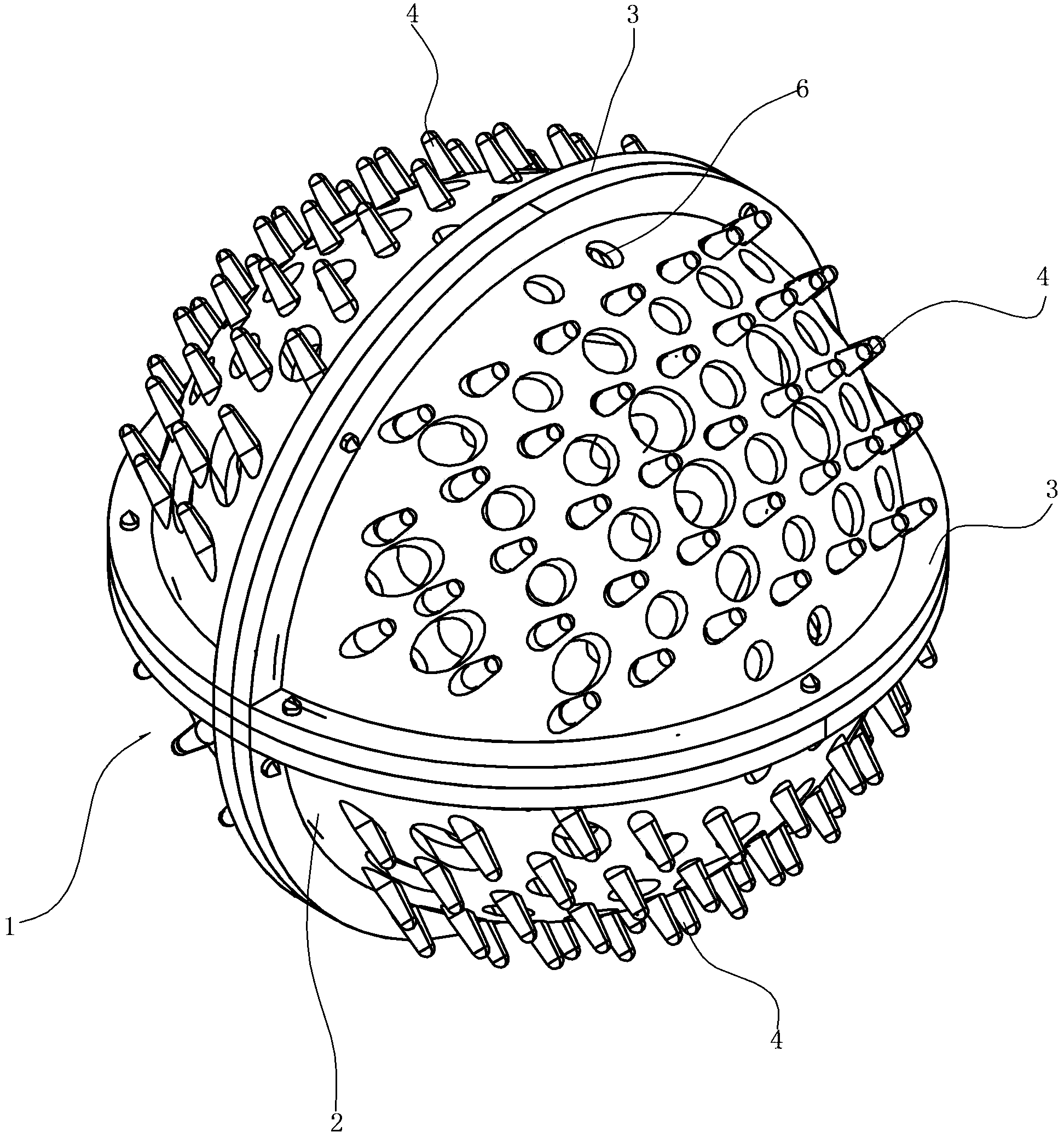

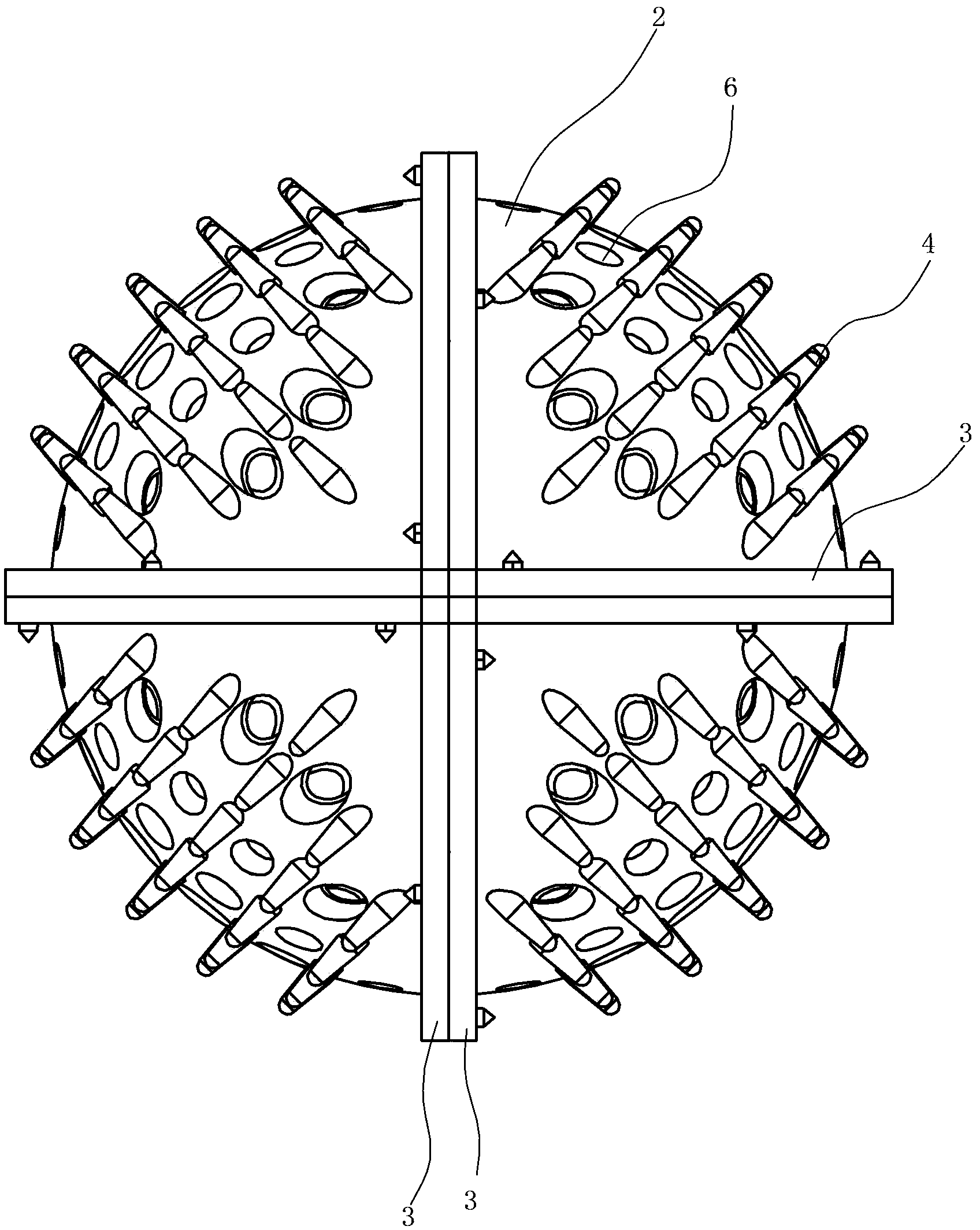

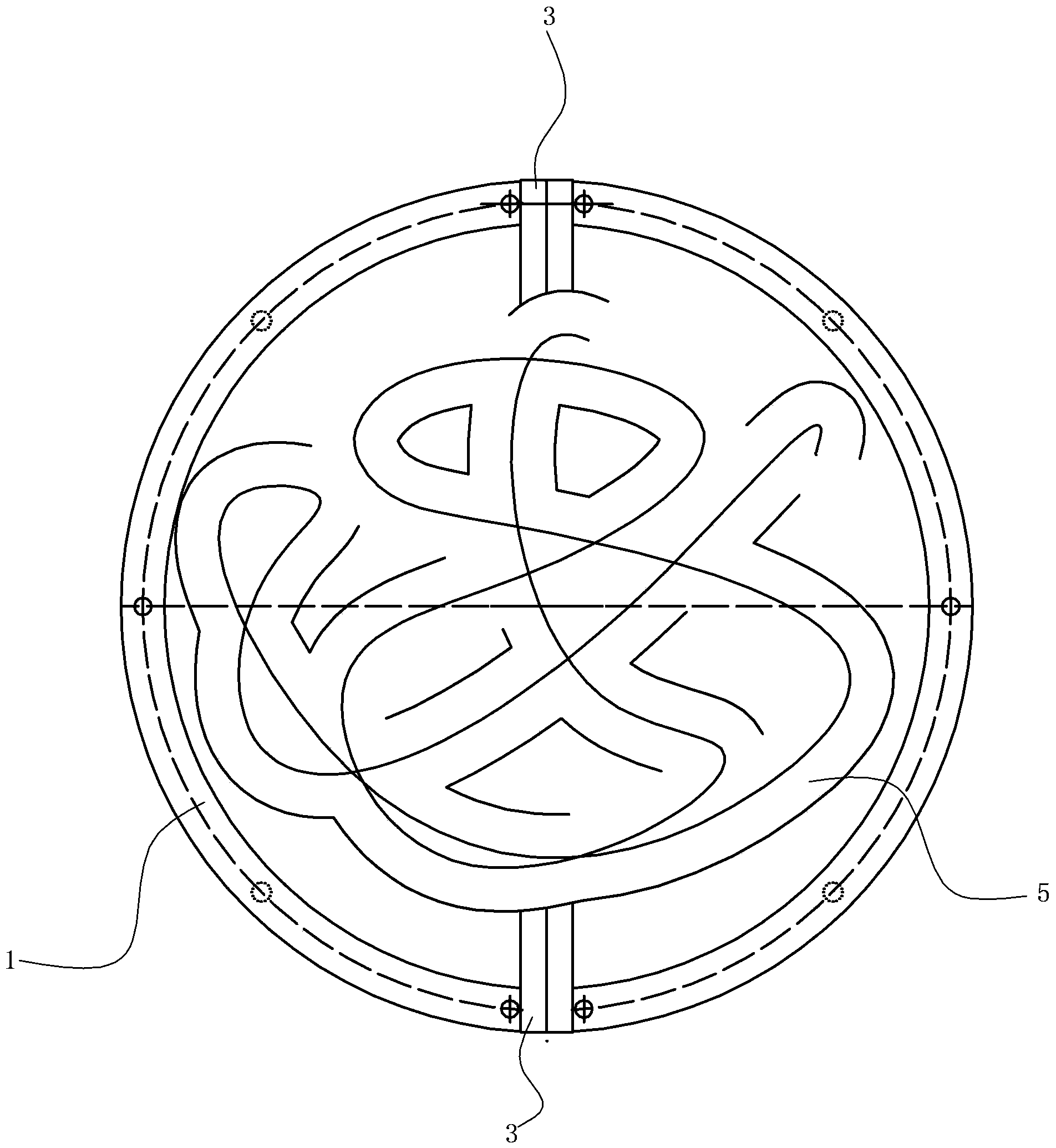

[0023] Such as Figure 1 to Figure 8 As shown, the AO reactor for water treatment includes:

[0024] The housing 1 is a hollow structure and is assembled from a plurality of housing petals 2 . The shell in this embodiment has a spherical structure with an uneven and rough surface, and is assembled from four identical shell petals 2 . The end edge of each shell petal is respectively provided with a flange 3 protruding from the outer surface of the shell, and each flange is respectively provided with a corresponding boss 7 and a slot 8, through the cooperation of the boss and the slot, the The shell petals are joined together to form the shell.

[0025] The casing 1 is provided with a plurality of through holes 6 , and the sum of the areas of each through hole is 70%-80% of the surface area of the casing, which is 75% in this embodiment. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com