Spacer, connector and insulating glazing

A technology for spacers and glass windows, which is applied in connection, window/door, building construction, etc., and can solve the loss of airtightness of isolation glass windows, the limitation of the possibility of dimensioning of isolation glass windows, the damage of butyl rubber bands, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

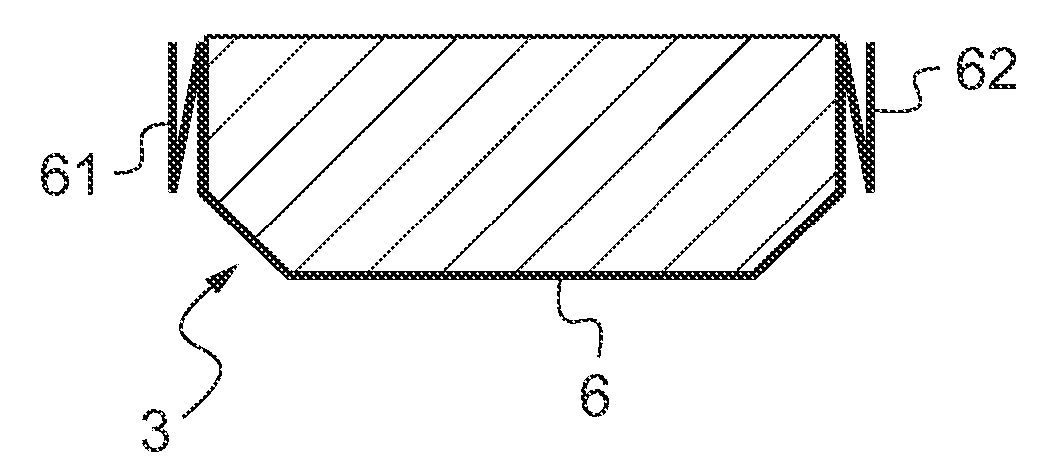

[0031] The invention proposes a spacer for an insulating glazing, comprising a longitudinal body equipped with two longitudinal sides and two membranes or membrane parts intended to be fixed each to a pane of the insulating glazing . Each diaphragm or diaphragm portion is adapted to be hinged to the body about an axis parallel to the longitudinal axis of the body in a position where the diaphragm or diaphragm portion rests on a longitudinal side of the body and at least partially aligned with the longitudinal direction of the body between side-separated positions. Thus, each membrane or membrane part forms a hinge with respect to the main body.

[0032] When the insulating glazing is deformed under wind loads or climatic loads, the deformation of the glass pane is taken care of by the diaphragm or part of the diaphragm which forms a hinge with respect to the body, the hinge allowing the diaphragm or part of the diaphragm to move away from the body, at the same time due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com