High-strength low-tension cable combined by optical fibers

A technology of optical fiber composite and low-voltage cables, which is applied in the field of power cables and optical communications. It can solve the problems of optical unit damage, scrapping, and failure of normal operation of optical fiber composite low-voltage cables, so as to reduce the construction period, reduce costs, and solve the problems that are easily affected by external forces. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

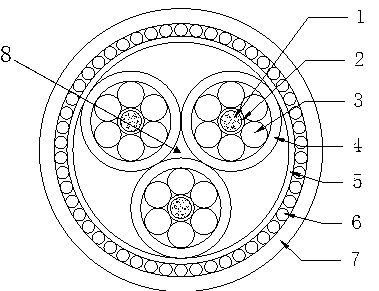

[0011] Such as figure 1 As shown, a high-strength optical fiber composite low-voltage cable according to the present invention includes a cable core. The gap of the core is provided with a filling tape 8, and the inner sheath 5, the armor layer 6 and the outer sheath 7 are sequentially covered outside the cable core; the conductor is an optical unit assembly structure, which is composed of the optical unit and the coating A plurality of metal wires 3 outside the optical unit are twisted. The optical unit is composed of an optical fiber and a steel loose tube wrapped around the optical fiber. Cable paste is also filled between the optical fiber 1 and the steel loose tube 2, and the excess length of the optical fiber 1 is controlled between 4‰ and 6‰.

[0012] The present invention provides a high-strength optical fiber composite low-voltage cable. The above is only a preferred implementation method of the present invention. Several improvements can be made, which should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com