Novel air inlet mixing system for supercharged and inter-cooling gas engine

A gas engine and hybrid system technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of high use and maintenance costs, lack of economic conditions, complex structure, etc., to reduce system costs and be economically reasonable. , Technically feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

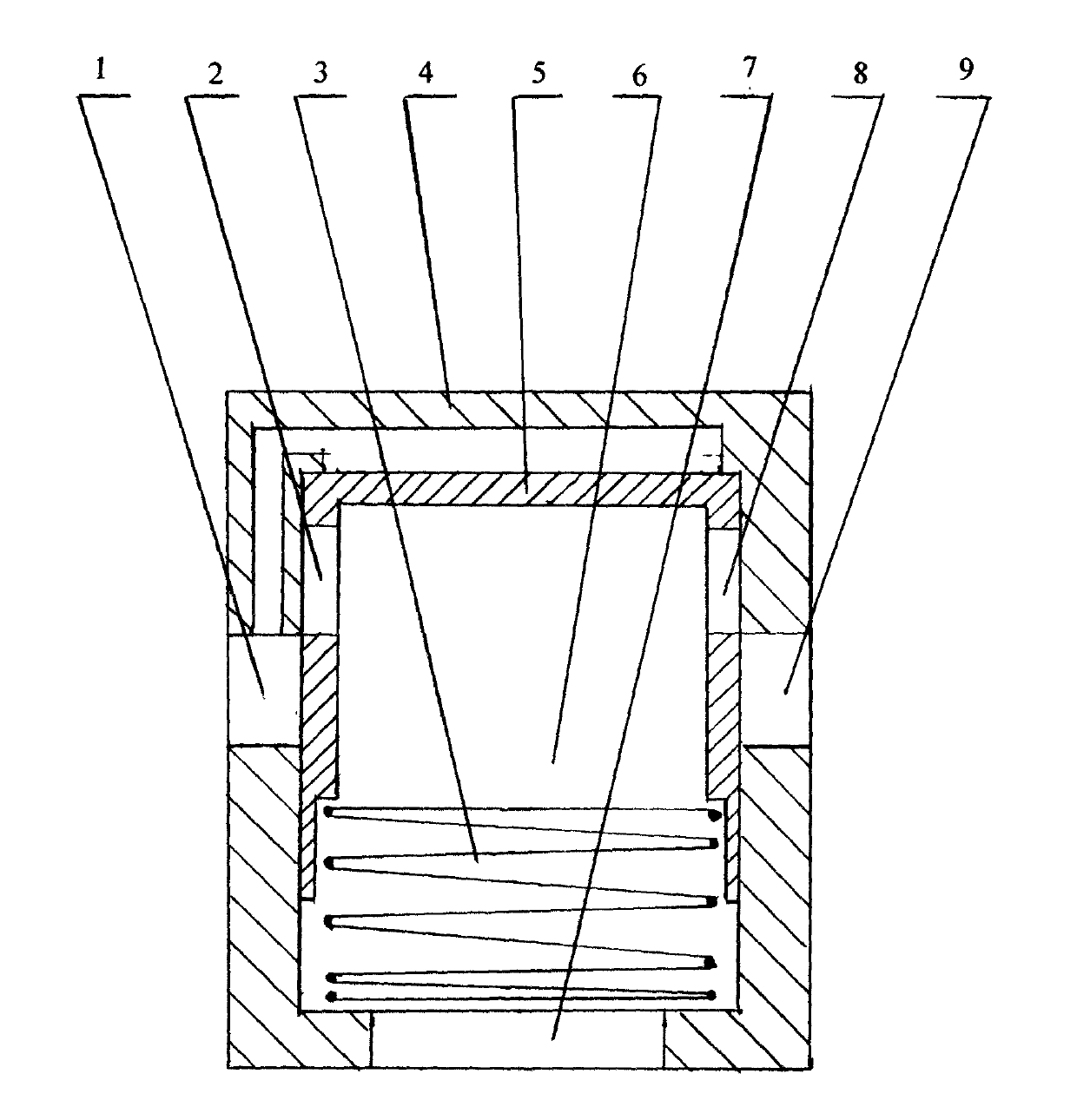

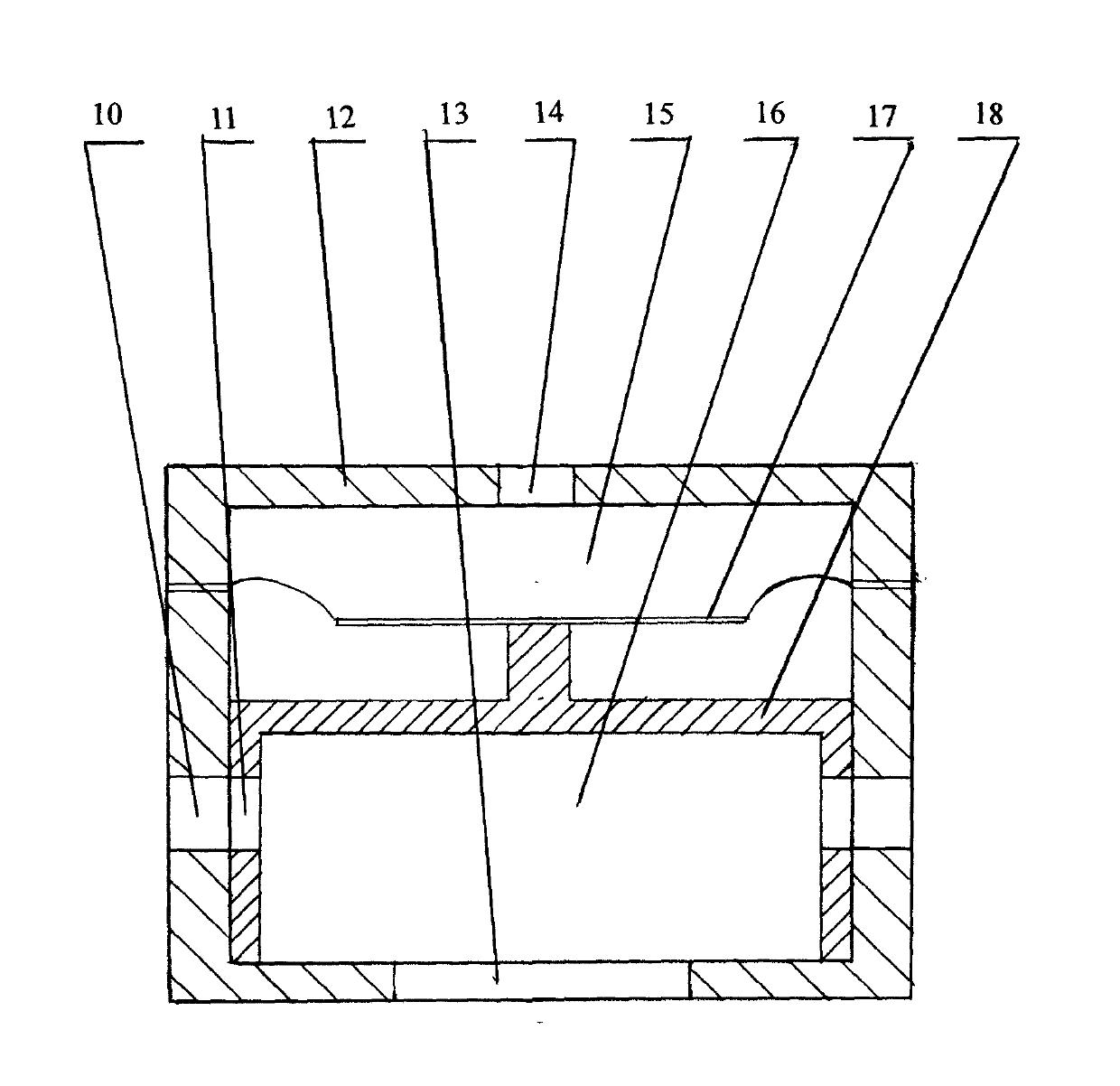

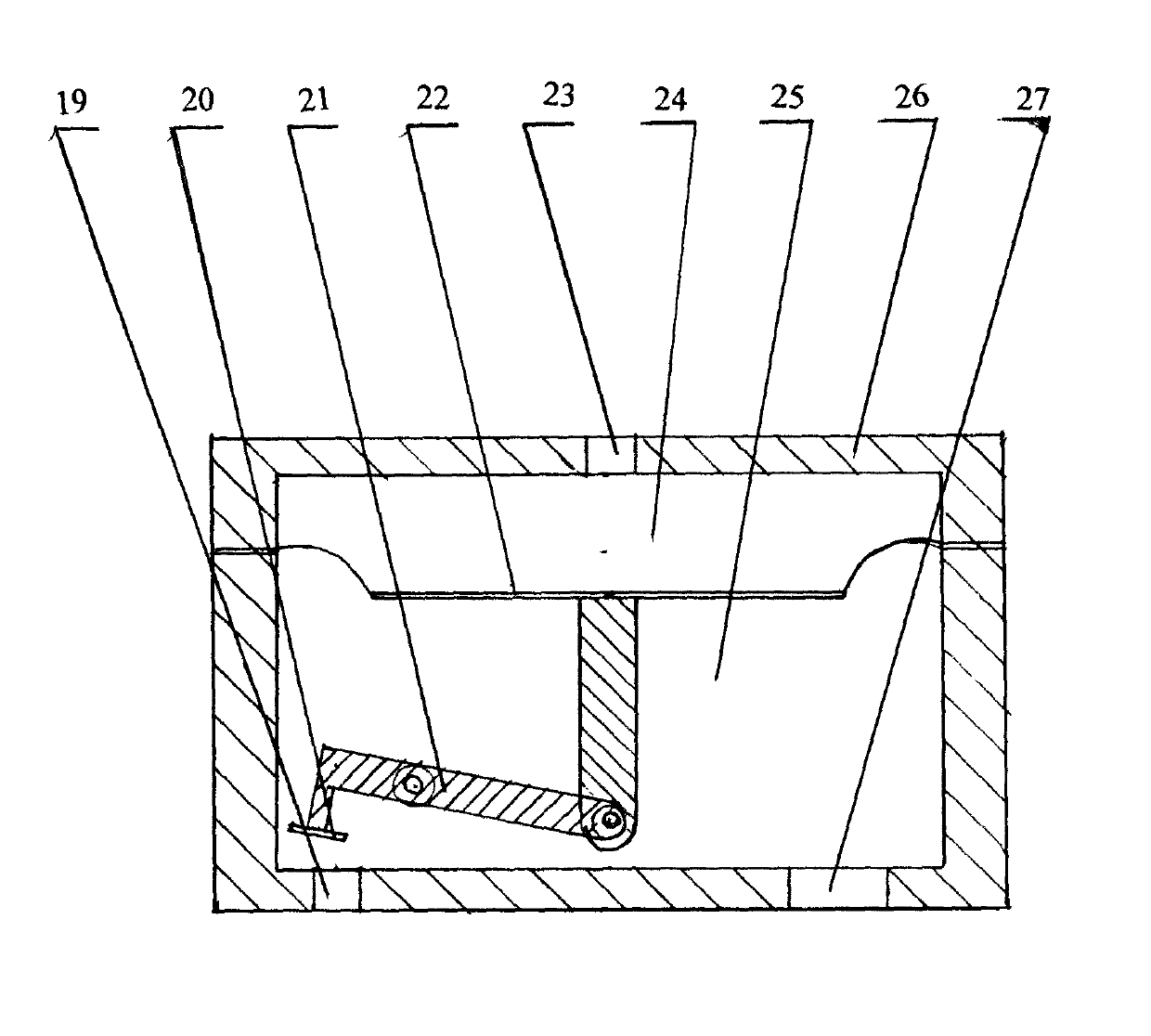

[0009] See accompanying drawing, the present invention is by: turbocharger, intercooler, vacuum mixer (attached figure 1 ), balancer (with figure 2 ), synchronous reducer (attached image 3 ) composition; the air input port of the turbocharger is connected to the air filter, and the air output port is connected to the input port of the intercooler; the vacuum mixer is composed of a mixer body 4, a regulating switch 5, and a constant pressure spring 3. The mixer body 4 is a cylinder-shaped structure, and the mixer body has a square air input port 1, a square gas input port 9, a combustible mixture gas input port 7, an air input port 1 and a balancer (attached). figure 2 ) is connected to the air outlet 13, and the gas inlet 9 is connected to the synchronous pressure reducer (attached image 3 ) is connected to the gas output port 27, the combustible gas mixture output port 7 is connected to the intake port of the engine, the regulating switch 5 is a piston-shaped structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com