Hydraulic oil composition and method for preparing same

A hydraulic oil composition and high-pressure technology, applied in the field of hydraulic oil, can solve the problems of poor annealing cleanliness, high residual carbon and ash index, application influence, etc., and achieve good annealing cleanliness, reduce annealing oil spots, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

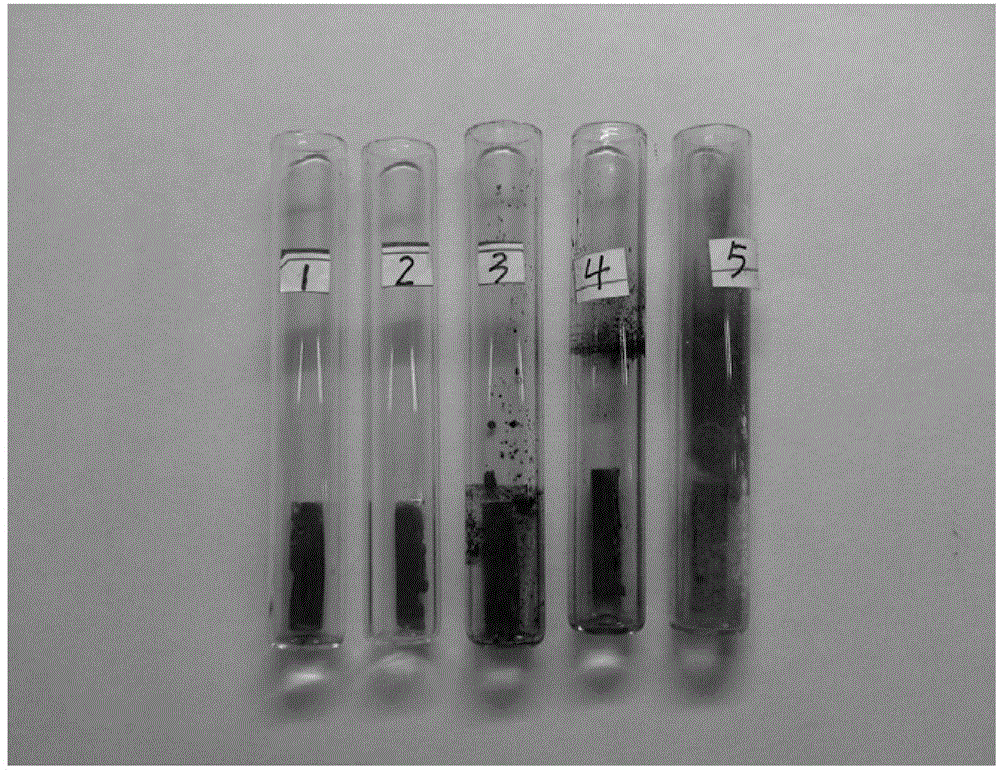

Image

Examples

preparation example Construction

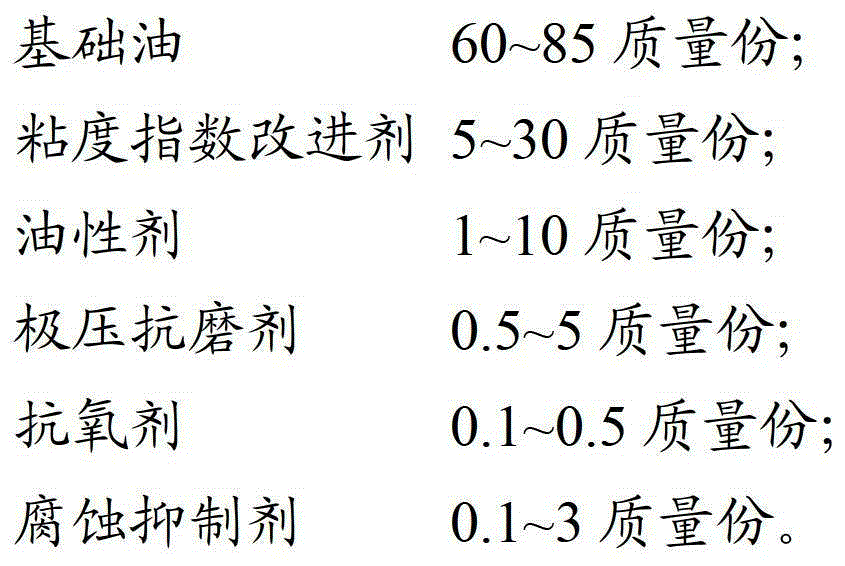

[0029] The invention also provides a preparation method of the hydraulic oil composition, which comprises the following steps:

[0030] The viscosity index improver, oiliness agent, extreme pressure antiwear agent, antioxidant, corrosion inhibitor and base oil are mixed, heated and stirred to obtain a hydraulic oil composition.

[0031] In the present invention, the base oil is preferably added to the mixing kettle first, and then the viscosity index improver, oiliness agent, extreme pressure antiwear agent, antioxidant, and corrosion inhibitor are added. The present invention has no limitation on the way of feeding.

[0032] In the present invention, the heating temperature is preferably 50°C to 80°C, more preferably 55°C to 75°C. The present invention has no limitation on the mixing and stirring, as long as the mixing and stirring are well known to those skilled in the art.

[0033] In the present invention, the base oil is preferably mineral oil, which may be paraffin oil or naphth...

Embodiment 1

[0043] Add 70g poly-α-olefin synthetic oil PAO2 into the mixing kettle, and then add 10g polyisobutylene (number average molecular weight of 1300 Daltons), 8g butyl stearate, 4g tricresyl phosphate, 0.4g diphenylamine, 2g2- Aminoethyl heptatenyl imidazoline succinate is mixed, heated to 50° C. and stirred uniformly to obtain a hydraulic oil composition.

[0044] The hydraulic oil composition prepared in Example 1 was measured for kinematic viscosity according to GB / T265, viscosity index was measured according to GB / T2541, acid value was measured according to GB / T7304, and corrosion performance was measured according to GB / T5096 , According to GB / T260 for moisture determination, GB / T17144 for residual carbon value determination, GB / T508 for ash determination, GB / T511 for mechanical impurity determination, and GB / T1690 for material suitability and volume The results of the change measurement are shown in Table 1. Table 1 is the performance measurement result of the hydraulic oil co...

Embodiment 2

[0046] Put 85g of Type II base oil 60N into the mixing kettle, then add 20g polyisobutylene (number average molecular weight of 600 Daltons), 4g oleic acid, 1g di-n-butyl phosphite, 0.2g 2.6-di-tert-butyl pair The cresol and 1 g of benzotriazole are mixed, heated to 80° C. and stirred uniformly to obtain a hydraulic oil composition.

[0047] The hydraulic oil composition prepared in Example 2 was measured for kinematic viscosity according to GB / T265, viscosity index was measured according to GB / T2541, acid value was measured according to GB / T7304, and corrosion performance was measured according to GB / T5096 , According to GB / T260 for moisture determination, GB / T17144 for residual carbon value determination, GB / T508 for ash determination, GB / T511 for mechanical impurity determination, and GB / T1690 for material suitability and volume The results of the change measurement are shown in Table 1. Table 1 is the performance measurement result of the hydraulic oil composition provided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com