Explosion-proof skid-mounted refueling device and protective shed

The technology of a refueling device and a protective cover is applied in the directions of distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., and can solve the problems of unfavorable promotion and use of skid-mounted refueling devices, waste of land, man-hours and funds, and small sheds, etc. To achieve the effect of easy promotion, convenient installation, good explosion-proof safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

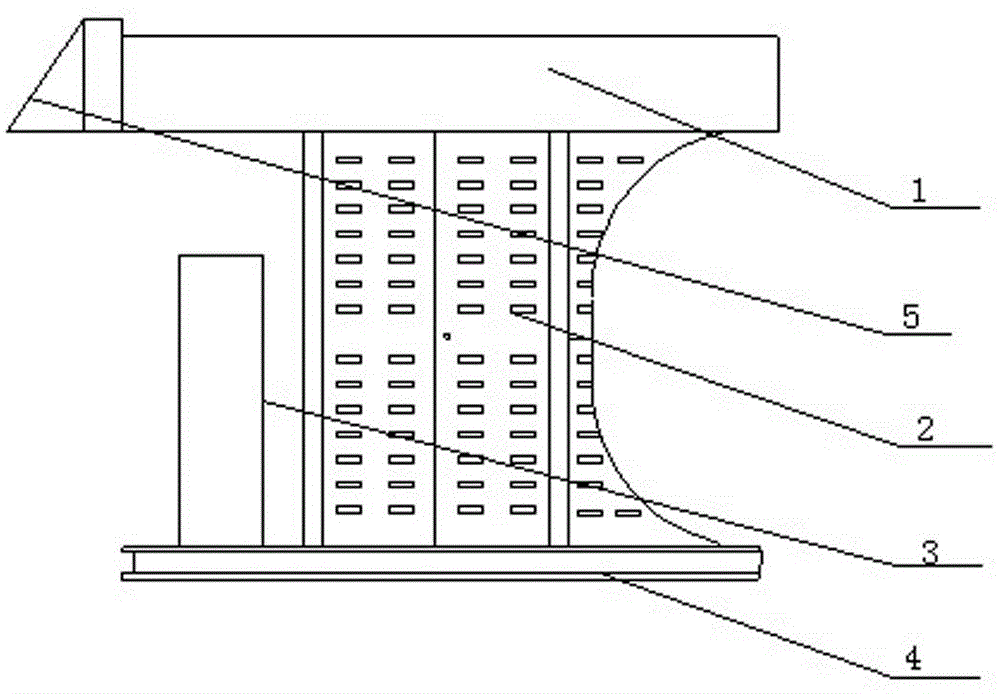

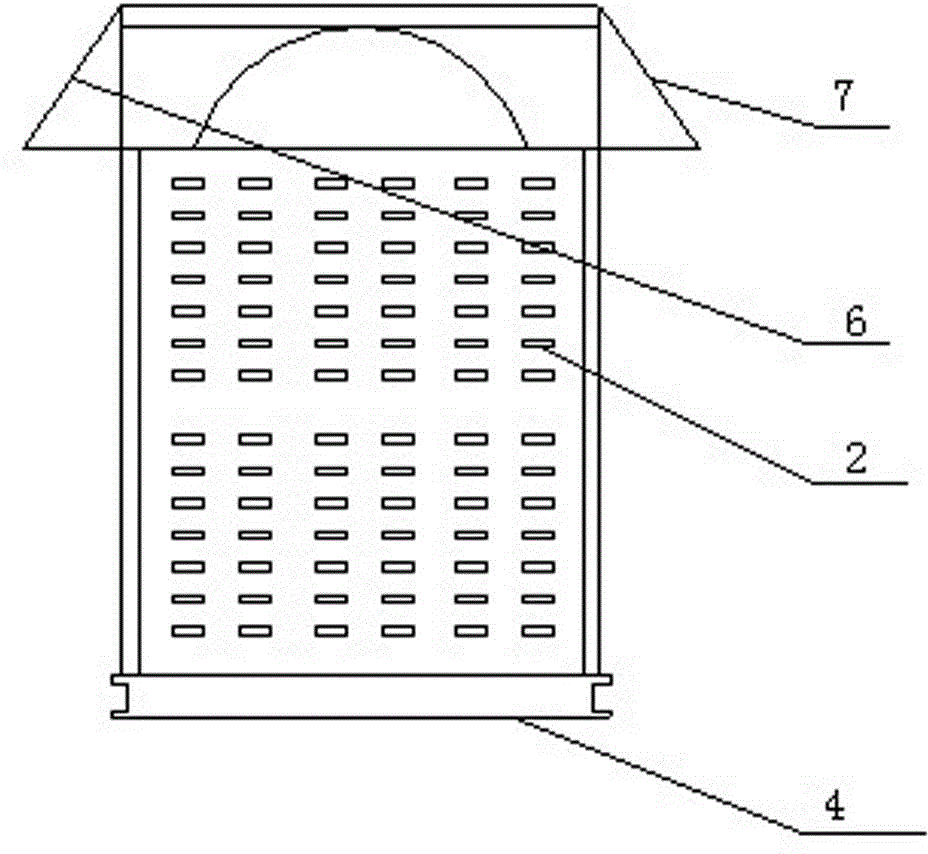

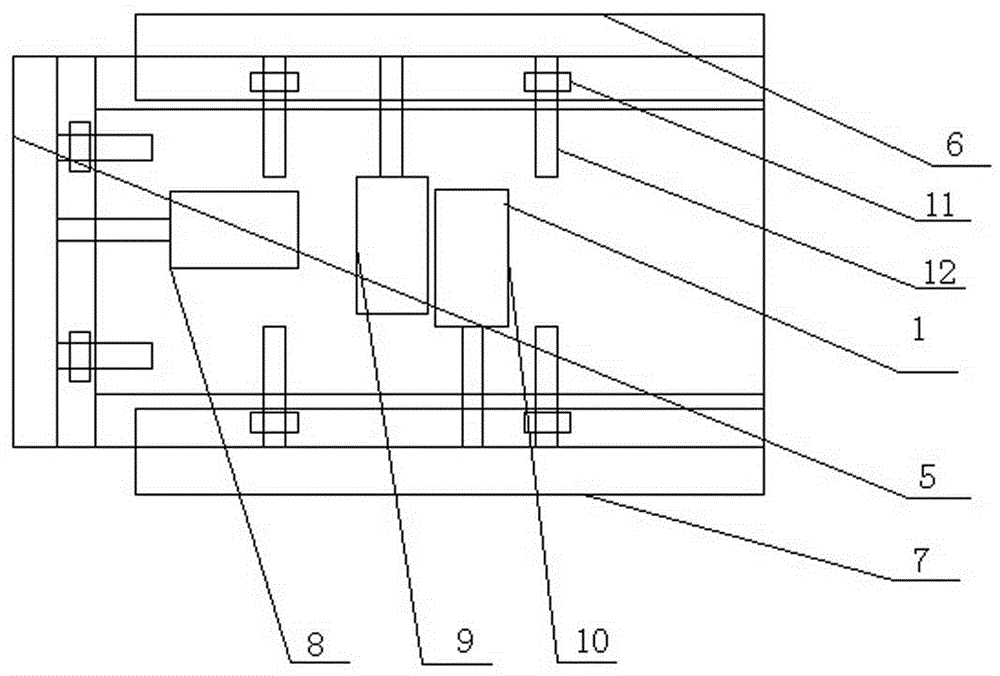

[0014] Depend on figure 1 , figure 2 As shown in the schematic diagram, it can be seen that the expansion cover of the barrier explosion-proof skid-mounted refueling device of the present invention mainly includes the refueling device and the expansion cover.

[0015] The refueling device mainly includes a base 4, a fuel dispenser 3, a power distribution room 2, and a top fixed shed 1. One side close to the outer end, and the fuel dispenser 2 is located between the top fixed cover 1 and the base 4 .

[0016] An oil pump is arranged in the power distribution room 2, and the oil pump is connected with the fuel dispenser 2.

[0017] The extended canopy is composed of three small canopies. The small canopy is rectangular, and they are small canopy A5, small canopy B6 and small canopy C7. 1 The three side ends close to the tanker are connected, wherein the small canopy B6 and the small canopy C7 are respectively located at the two ends of the top fixed canopy 1, and the small c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com