Display screen silk-screen printing positioning clamp

A technology of screen printing and positioning fixtures, which is applied to screen printing machines, printing machines, printing machines, etc., and can solve problems such as poor printing, printing fragments, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

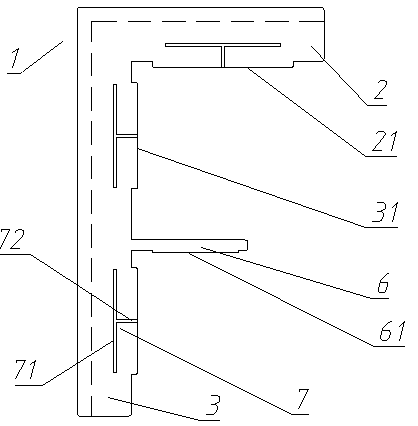

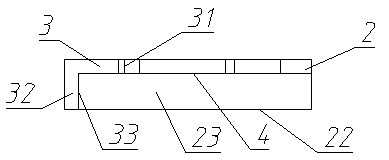

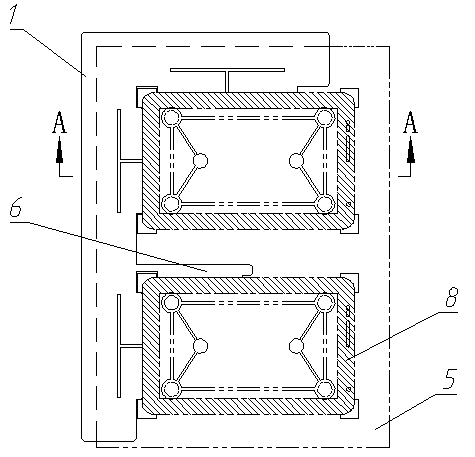

[0016] An embodiment of the screen printing positioning fixture of the present invention Figure 1~Figure 5 As shown, the screen printing positioning fixture for the display screen includes a clamp body 1, which includes a transverse positioning plate 2 and a longitudinal positioning plate 3 connected in an L-shaped butt connection, and the transverse positioning plate 2 and the longitudinal positioning plate 3 are both It has a lower surface 4 for mating and fitting with the upper surface of the corresponding plate loading jig. The butt of the horizontal positioning plate 2 and the vertical positioning plate 3 has an inner corner corresponding to the corner of the display screen 8. The horizontal positioning plate 2 and the longitudinal positioning plate 3 both have inner sides connected to the inner corners and perpendicularly connected to the lower surface 4. The inner side of the transverse positioning plate 2 includes a transverse edge corresponding to the display screen 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com