Novel rice pot seedling transplanter and seedling raising plate, seeder, seeding pulling frame and clamp matched with transplanter

A technology for raising seedling trays and seedling pots, which is applied in the field of agricultural machinery and tools, can solve problems such as incomplete coordination, imperfect parts, and unfavorable transmission, and achieve the effects of uniform and adjustable row spacing, simple and reasonable structure, and accurate mutual cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

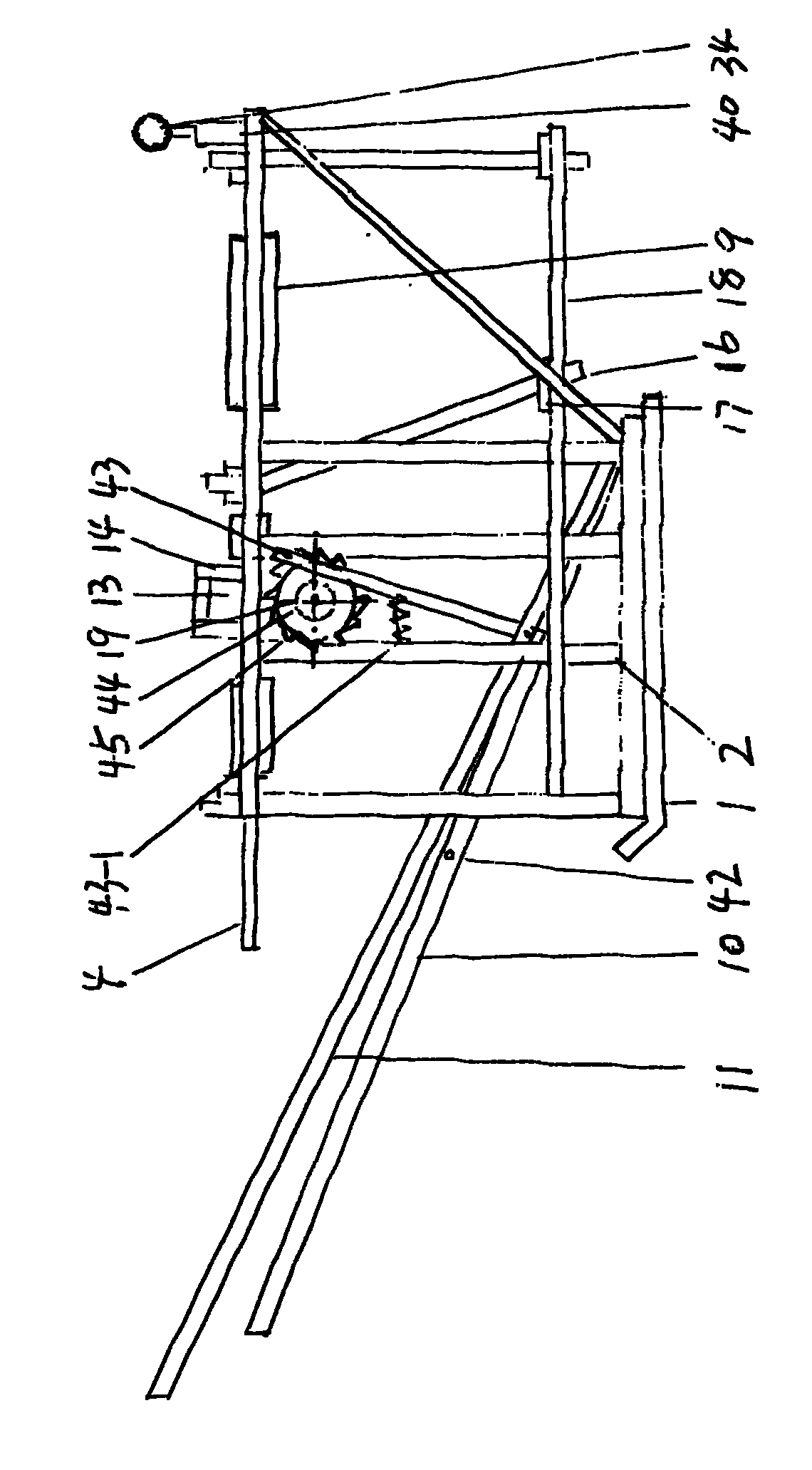

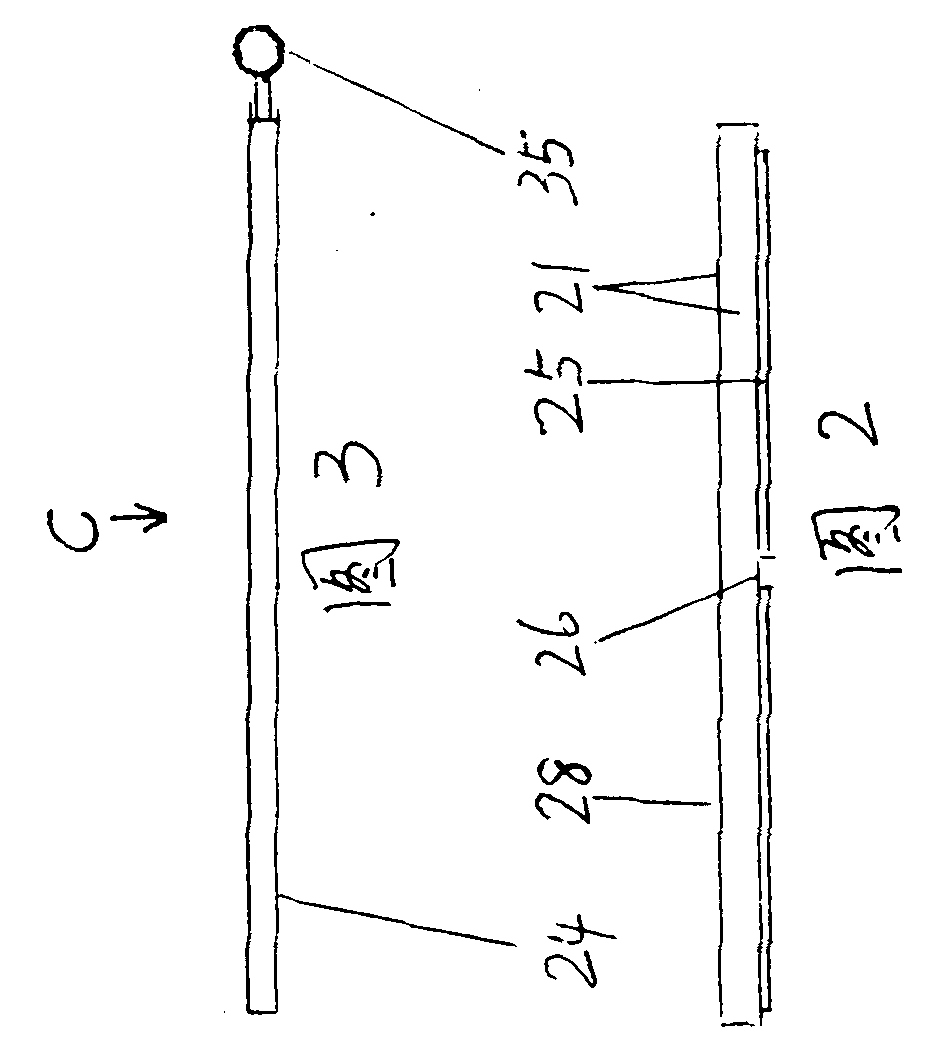

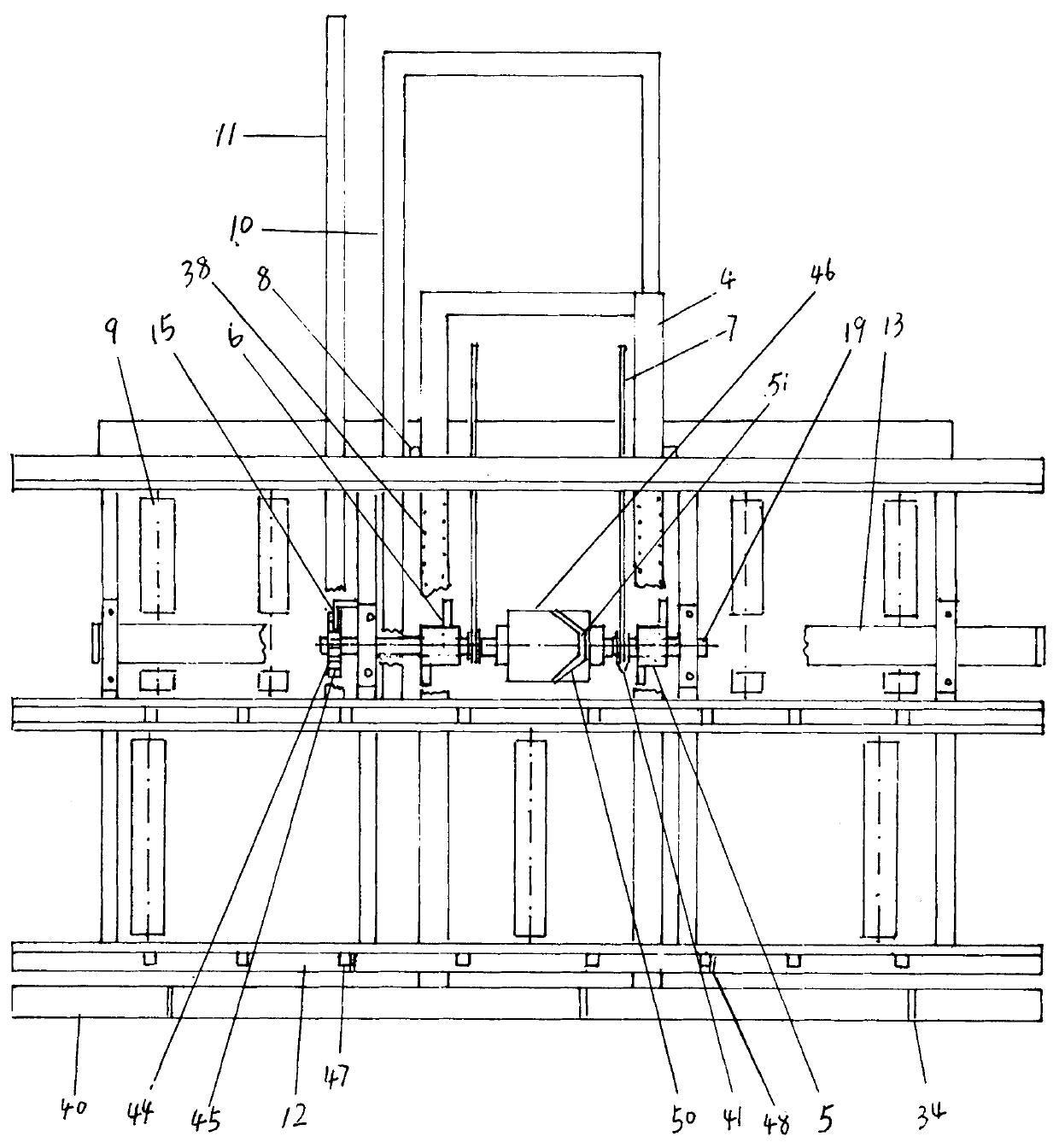

[0033] The present invention will be further described in detail below in conjunction with the specific embodiments of the accompanying drawings.

[0034] refer to Figure 1-Figure 11Among them, the rice pot seedling new planting machine of the present invention is made up of ship bottom plate (1), frame (2), and seedling tray (3). The bottom plate of the ship is to support the whole machine to float on the muddy water in the field and to level the field surface. The frame (2) is equipped with: seedling tray (3), double straight tooth push rod (4), double straight tooth clutch (5) , straight tooth (6), double straight tooth clutch shift fork (7), double straight tooth push rod clamping pile (8) seedling plate moves left and right sliding drum (9), double arm pulling machine lever (10), right hand joystick ( 11), seedling drop slats (12), seedling plate moving left and right slats (13), seedling plate moving left and right slat clamping piles (14), ratchet anti-retraction stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com