Two-dimensional displacement-adjustable overturning mechanism

A technology of flipping mechanism and adjusting structure, which is applied to projectors, optics, and instruments with built-in screen/external screen, etc. It can solve the problems that the screw of the adjustment mechanism is easy to get stuck, the screen cannot be opened and reset, and the requirements for high dimensional accuracy are achieved. The adjustment method is simple, convenient and reliable, the connection method is simple and reliable, and the effect of simplifying the adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

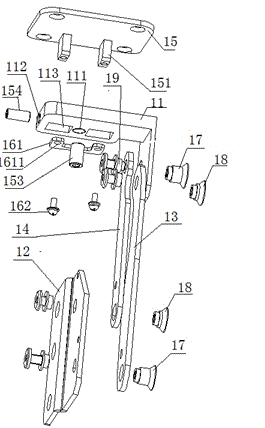

[0033] Such as Picture 1-1 As shown in 2, a turning mechanism 1 capable of adjusting displacement in two dimensions includes a turning member 11, a fixing member 12 for mounting on the box body 3, a long connecting rod connected to the fixing member 12 at one end and connected to the turning member 11 at the other end 13 and the short connecting rod 14 also include an adjustment structure 15 for being installed on the screen unit 2, the lower side of the adjustment structure 15 is provided with a downward protruding insertion part 151; The left and right adjustment holes 112 and the insertion holes 113 communicated with the left and right adjustment holes 112, the insertion part 151 passes through the insertion holes 113 and is installed on the flipper 11 through an anti-off component 16, and one end is installed on the upper and lower adjustment holes 111 against the adjustment structure 15. The upper and lower adjustment parts 153 on the lower side, and the left and right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com