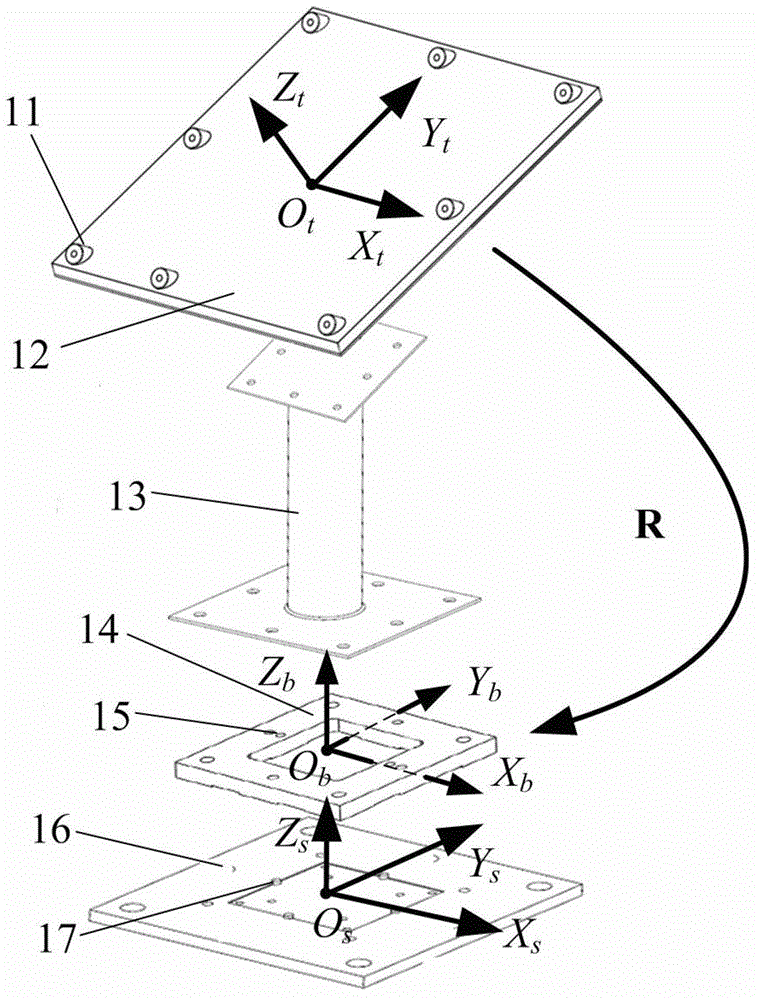

Visual target plate device for calibrating component mounting attitude and calibration method

A calibration method and visual technology, applied in the field of visual measurement, can solve problems such as difficulty in ensuring accuracy, inability to realize digital real-time tracking measurement and calibration, and inability to adapt to technological development trends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

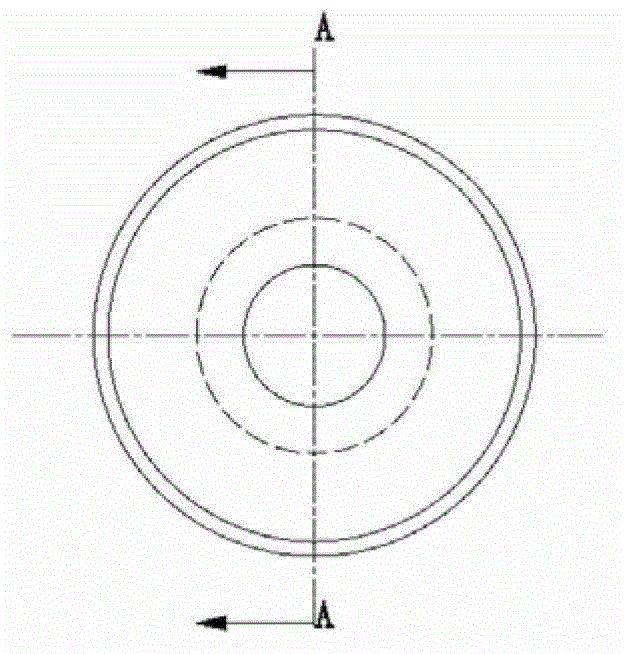

[0078] The camera imaging system used in all experiments in this example is: Basler A102f camera, image resolution 1394×1040pixel 2 , The nominal focal length of the lens is 12.5mm, and an infrared filter is installed at the front to filter out visible light.

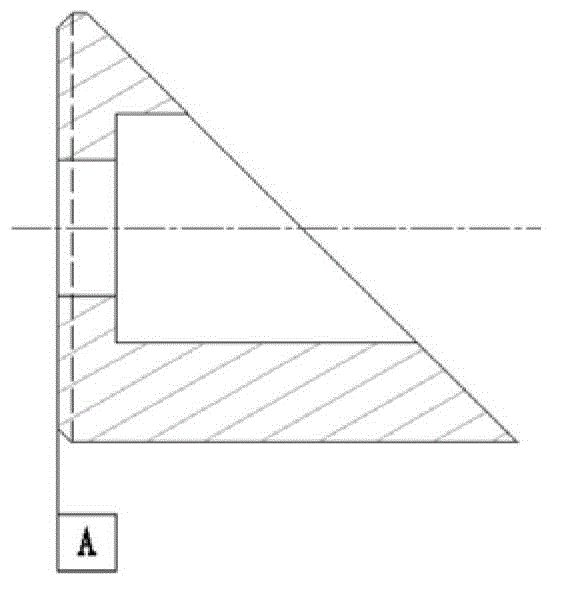

[0079] The relative position of the optical target point is calibrated by NH-SK CNC machine tool to control the precise movement of the auxiliary target point, and the effective stroke of the machine tool is 1000×600×550mm 3 , the freedom of movement in the three directions of the X, Y, and Z axes of the machine tool is on the tool. Fix the target board in the middle of the working table of the machine tool. An infrared LED optical target auxiliary target is fixed at the tool clamping base. The camera is placed about 6m away from the target board.

[0080] The two preset coordinate positions (unit mm) in the machine tool coordinate system are (0.00, 588.00, 485.00) and (955.00, 0.00, 0.00), then the standard length f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com