Single bottom adjustable valve bottom cleaning drill

An adjustable valve technology, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve the problems that the thickness of sediment does not meet the ideal requirements, affects the effect and progress of sludge removal, and is not easy to clean the sediment, so as to achieve saving Closing time, saving materials, and avoiding the effect of sediment leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

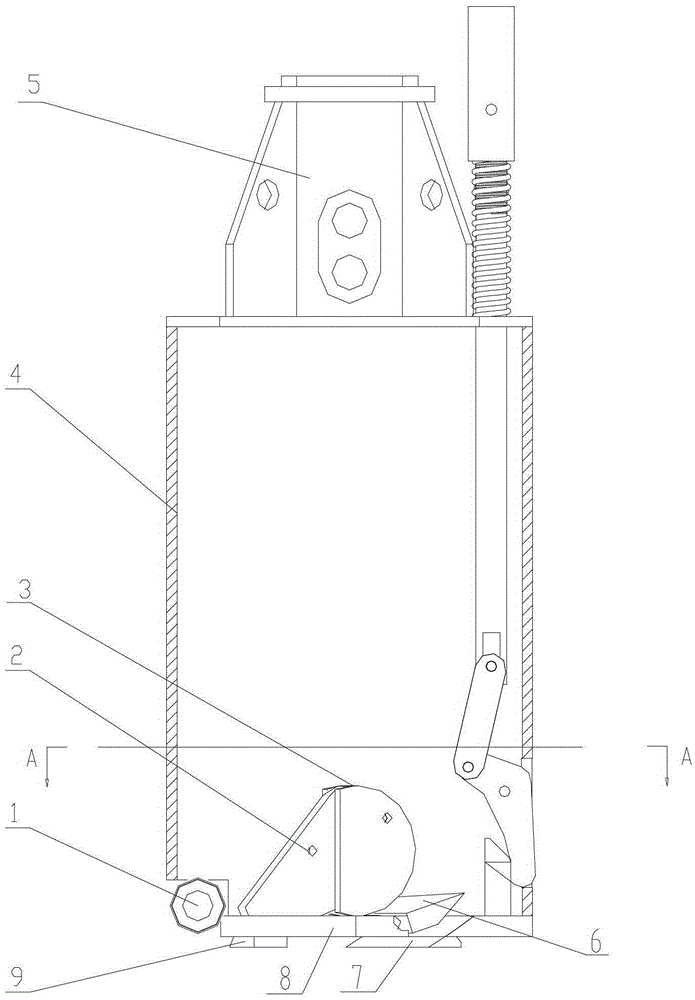

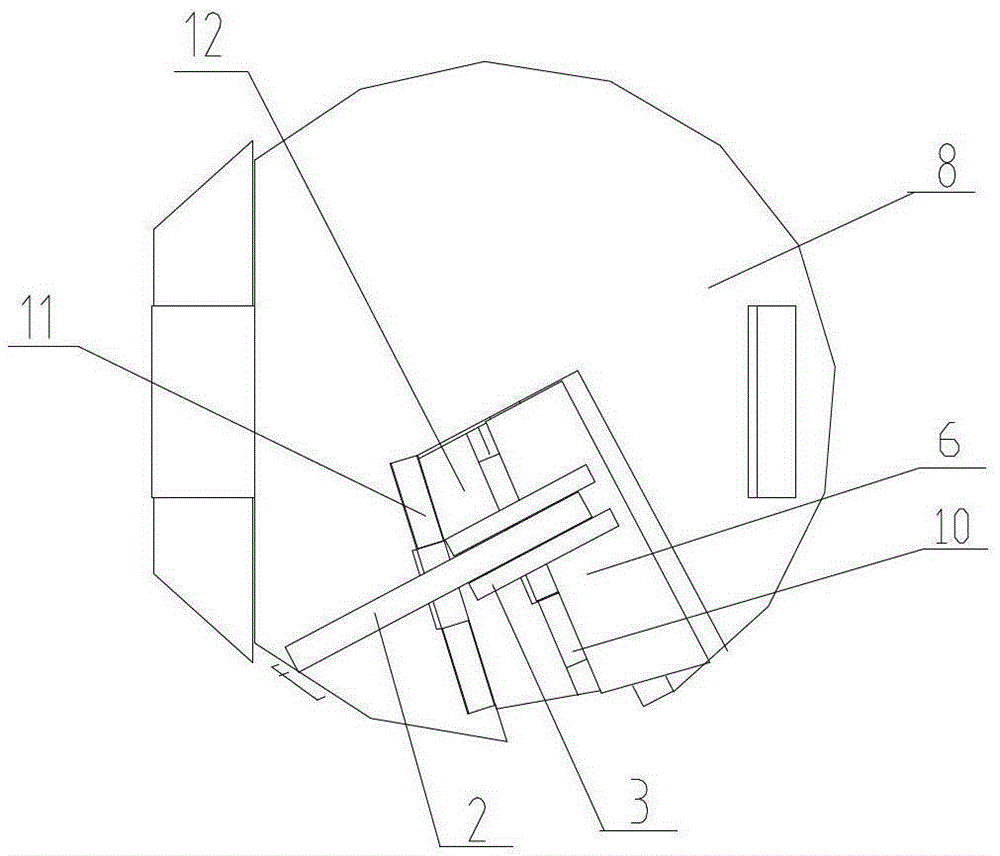

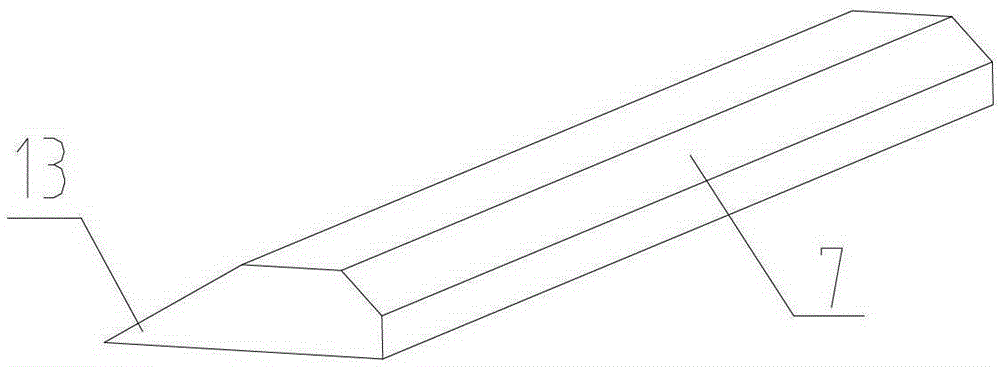

[0015] See Figure 1-Figure 5 , The present invention includes a bucket body 4 and a cleaning bottom plate 8 at the bottom of the bucket body 4. The cleaning bottom plate 8 is provided with a slag inlet, and a scraper 7 is installed under the cleaning bottom plate 8. The key technology is that the cleaning bottom plate 8 is a single-bottom cleaning bottom plate. A shutter mechanism is installed on the cleaning bottom plate 8 at the slag inlet through a second hinge 11. The shutter mechanism includes a first cover plate 6 and a second cover plate 12. The cover plate 6 and the second cover plate 12 are connected by the first hinge 10, and a valve adjustment mechanism is installed on the cleaning bottom plate 8 at a position corresponding to the valve mechanism. The valve adjustment mechanism includes a limit control board 2 and a pin and a limit control board. 2 connected arc-shaped limit plate 3.

[0016] A soil drainage plate 9 is also installed under the cleaning bottom plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com