Conveying device

A technology of conveying device and conveying part, which is applied in the directions of conveyor, transportation and packaging, can solve the problems of large clamping force of the connecting cup, small application range, and the bottom of the connecting cup is easily scratched, etc., and achieves high working stability, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

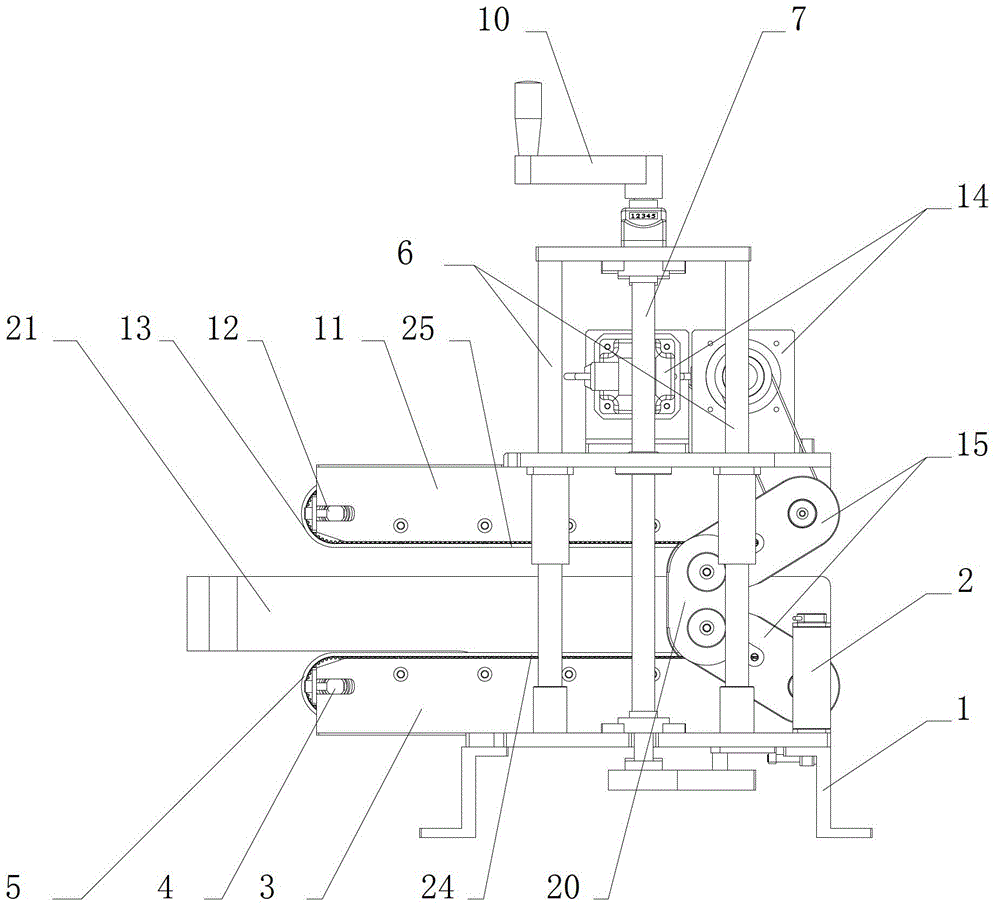

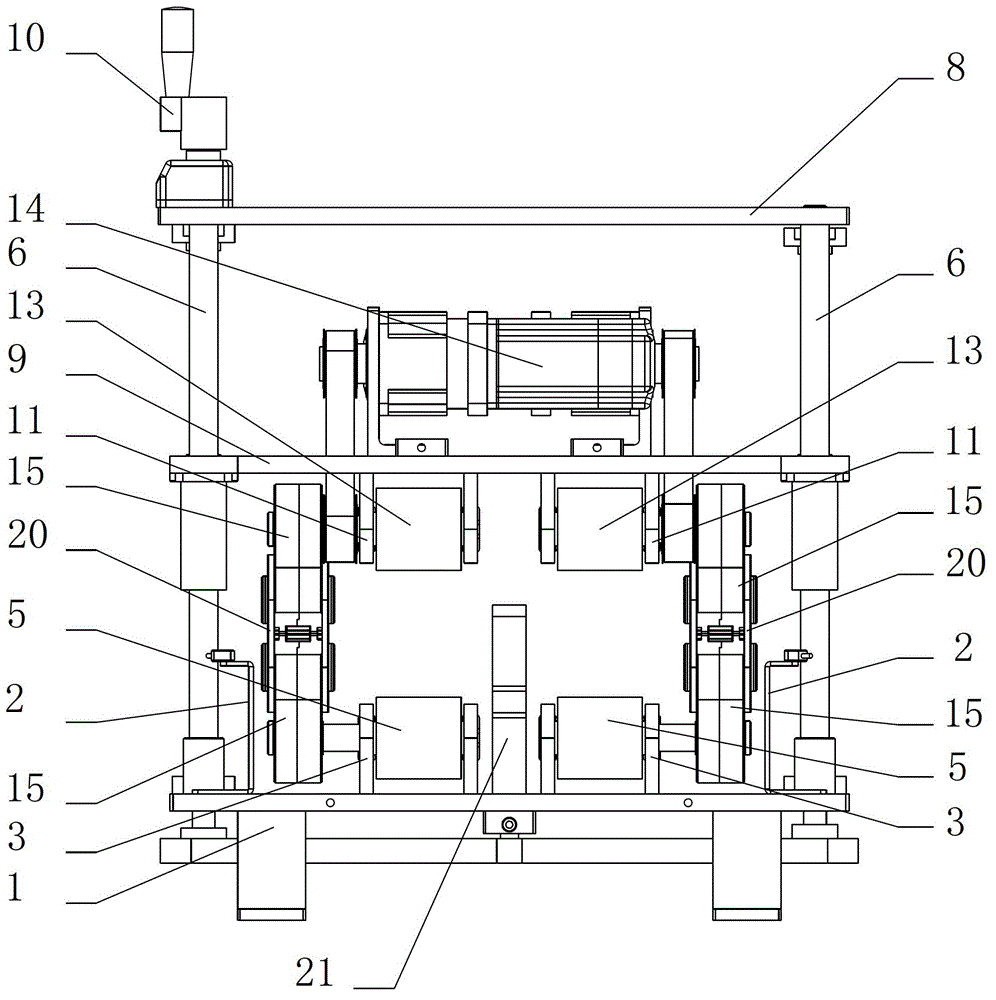

[0028] like figure 2 , 3 , 4, and 5, the conveying device includes a frame 1 and a clamping and conveying mechanism, and two clamping and conveying mechanisms are installed side by side on the frame 1. The clamping and conveying mechanism includes a conveying part I, a conveying part II, a transmission part, a power part 14 and a counting device 2 .

[0029] The conveying part I includes a bracket I3, a pulley I4, and a conveyor belt I5. The support I3 is fixedly connected to the frame 1, two pulleys I4 are installed on the support I3, and the conveyor belt I5 is installed on the two pulleys I4.

[0030] The frame 1 is provided with a lifting part, and the lifting part is located above the conveying part I. The lifting part includes a guide post 6, a screw mandrel 7, a top plate 8, and a mounting plate 9 for supporting and guiding. Four guide posts 6 distributed in a matrix are installed on the frame 1 , and the four guide posts 6 are in a parallel positional relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com