Engine Torque Fluctuation Compensation Method Based on Regular Curve Compensation Control Method

A technology of engine torque and curve compensation, applied in motor vehicles, hybrid vehicles, transportation and packaging, etc., can solve the problems of large engine torque fluctuations, affecting system efficiency, large torque fluctuations, etc., to reduce the range of torque fluctuations , wide range of applications, the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

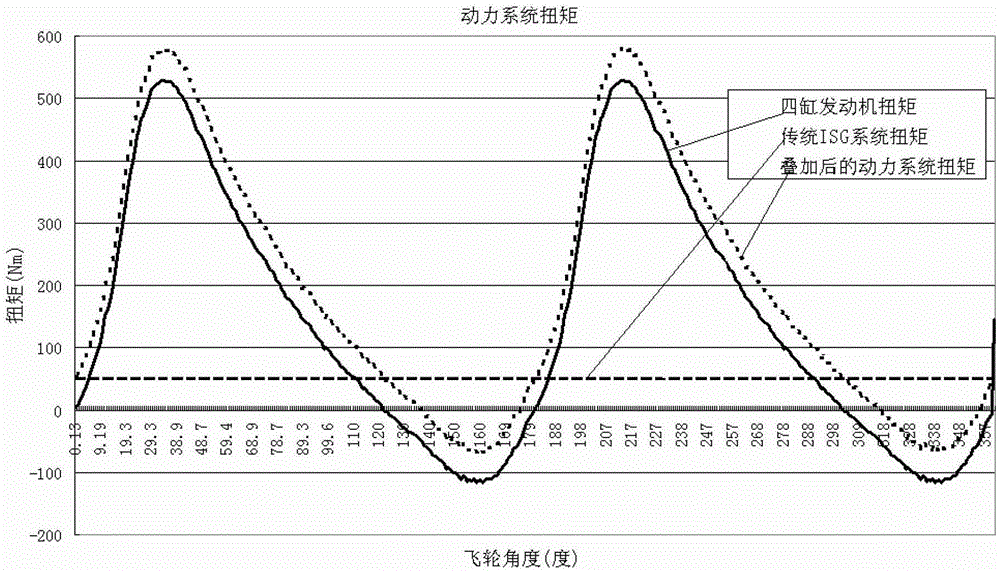

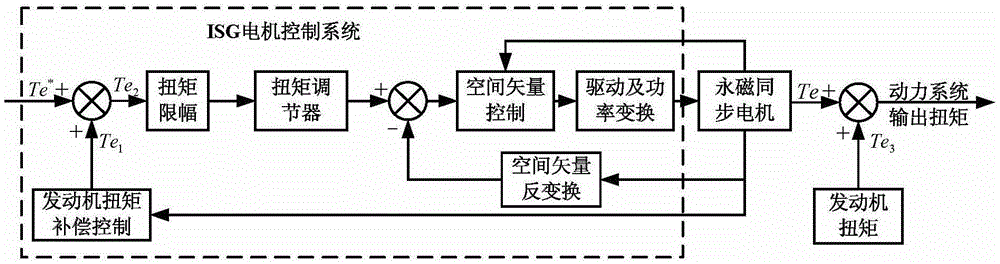

[0030] The engine torque compensation method based on the ISG system reduces the torque fluctuation effect of the power system and is related to the torque output capability and the torque command of the ISG system. The less obvious the effect of the system torque fluctuation is; on the contrary, the better the effect of reducing the torque fluctuation of the power system is. When the driving capacity of the ISG system is equivalent to the driving capacity of the engine, the output torque fluctuation of the power system can be reduced to zero in theory; and Using the torque compensation method, the output torque of the single-cylinder engine power system can be as stable as that of the multi-cylinder engine with the same displacement, and the vibration and noise of the system are also small.

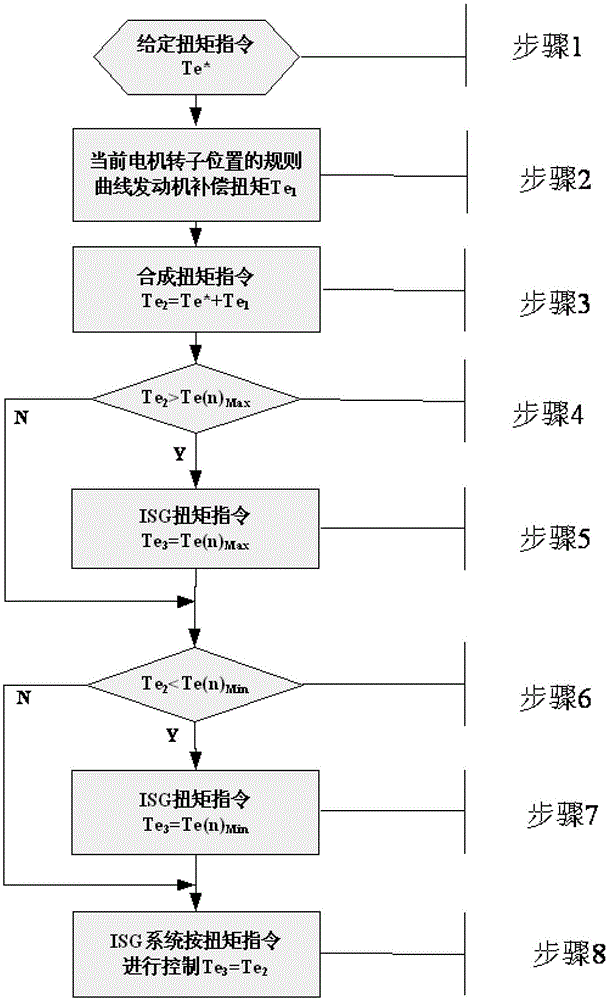

[0031] Based on the above content, the engine torque...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap