Discharging device and stirring vehicle

A technology of unloading device and mixer truck, which is applied in the direction of unloading device, clay preparation device, cement mixing device, etc. It can solve the problems of leakage to the construction site, etc., and achieve the effect of eliminating material leakage and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

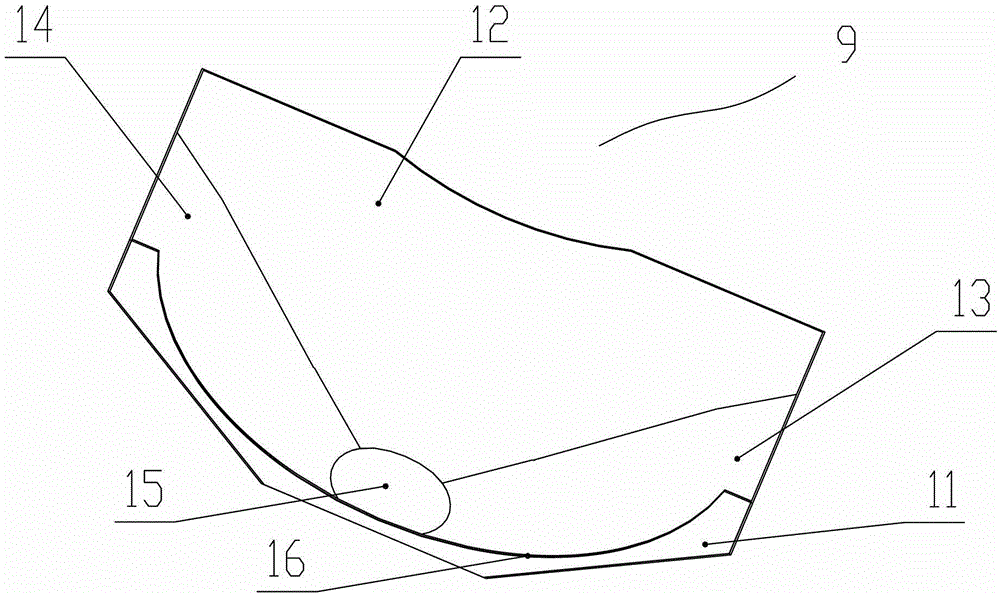

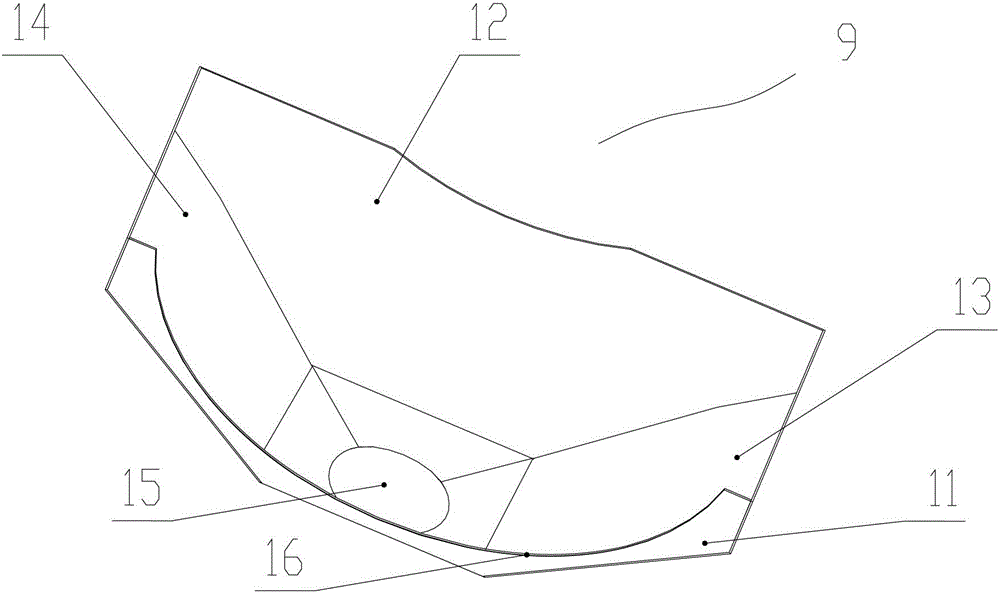

[0035] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Attached below Figures 2 to 13 Specific examples of the present invention will be described in detail.

[0036] For the convenience of expression, the orientation words in this article are limited as follows: Figure 5 , the top is up, the bottom is down, and the left and right are sides.

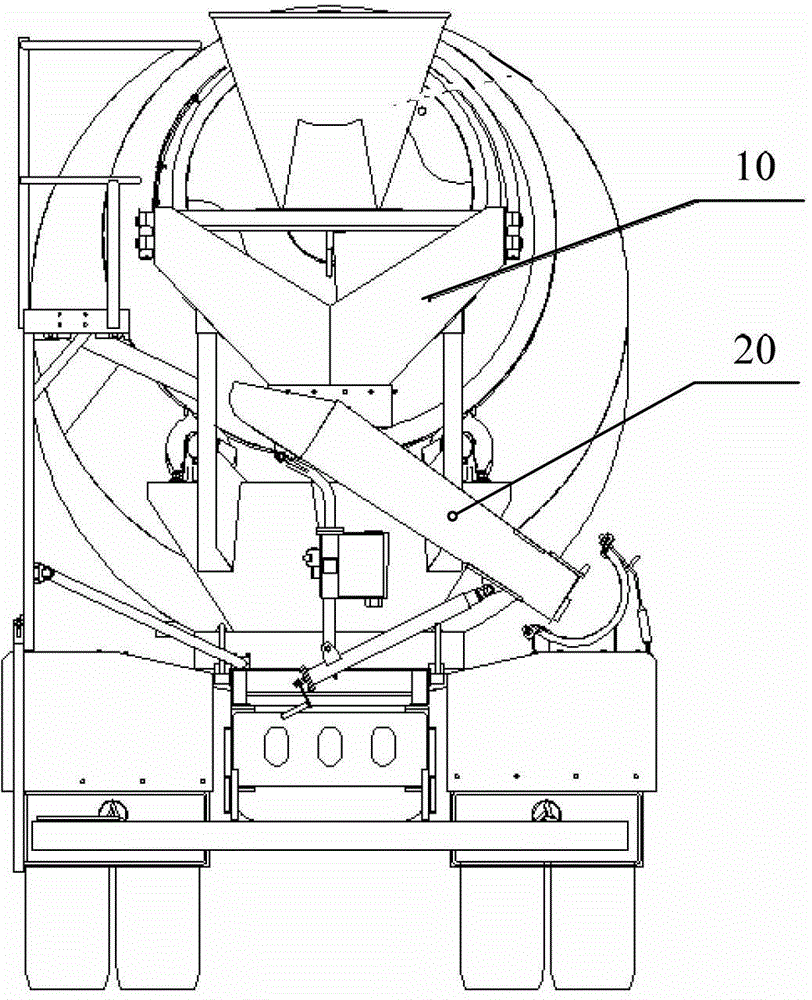

[0037] On the one hand, in order to prevent the problem of material leakage or material splashing out of the diversion tank during the unloading process of the mixer truck, a specific embodiment of the present invention proposes an unloading device, such as Figures 2 to 5 As shown, a discharge hopper 1 is included, and the discharge hopper 1 is provided with a material inlet and a discharge port 15; the discharge hopper is formed by sequentially connecting the first baffle plate 11, the left side plate 14, the second ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com