Ultra-narrow-row cotton planting method

A technology of ultra-narrow rows and cotton, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of easy scaffolding on fruit branches, low harvesting rate, poor defoliation effect, etc., and achieve good resistance uniformity , improved recovery rate and small growth difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

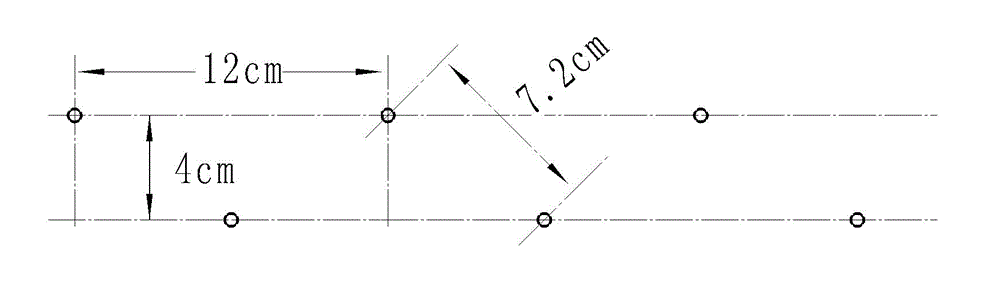

[0017] Example 1: Refer to attached figure 1 , is the schematic diagram of plant row spacing distribution of sowing in Example 1 of the present invention, the wide row spacing is 72cm, the narrow row spacing is 4cm, the plant spacing is controlled at 12cm, and the plants between the two narrow rows are arranged in a staggered manner, i.e. in a triangle, between the two narrow rows The distance between the plants of any of the above-mentioned plants was maintained at more than 7.2cm.

Embodiment 2

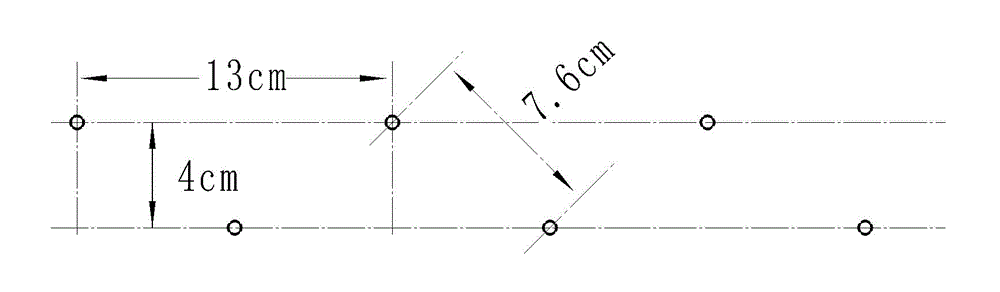

[0018] Example 2: Refer to attached figure 2 , is the schematic diagram of plant row spacing distribution of planting in Example 2 of the present invention, the wide row spacing is 72cm, the narrow row spacing is 4cm, and the plant spacing is controlled at 13cm. The distance between the plants of any of the above-mentioned plants was maintained at more than 7.6cm.

Embodiment 3

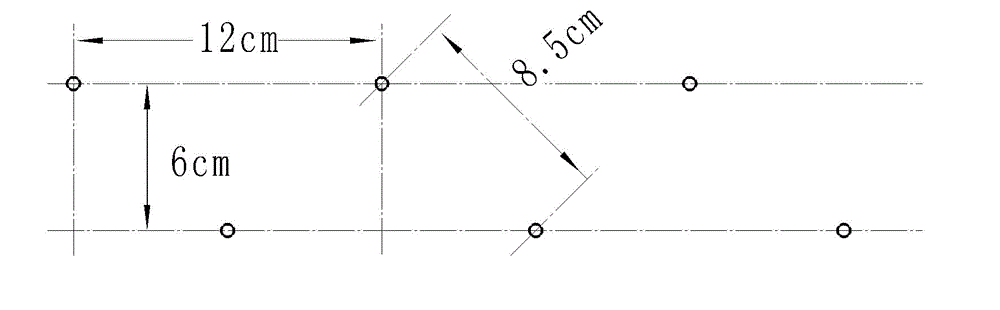

[0019] Example 3: Refer to attached image 3 , is the schematic diagram of plant row spacing distribution of sowing in Example 3 of the present invention, the wide row spacing is 70cm, the narrow row spacing is 6cm, the plant spacing is controlled at 12cm, and the plants between the two narrow rows are in a staggered distribution configuration, i.e. in a triangle, between the two narrow rows The distance between the plants of any of the above-mentioned plants was maintained at more than 8.5cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com