Key structure

A key and keycap technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as size reduction, complex assembly operations, and limited lifting characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides a button structure, which can be applied to any push-type input device, such as a keyboard, so as to effectively reduce the height of the buttons, simplify assembly complexity and satisfy the user's pressing habits. The structure and operation of each element of the key structure according to the embodiment of the present invention will be described in detail below with reference to the drawings.

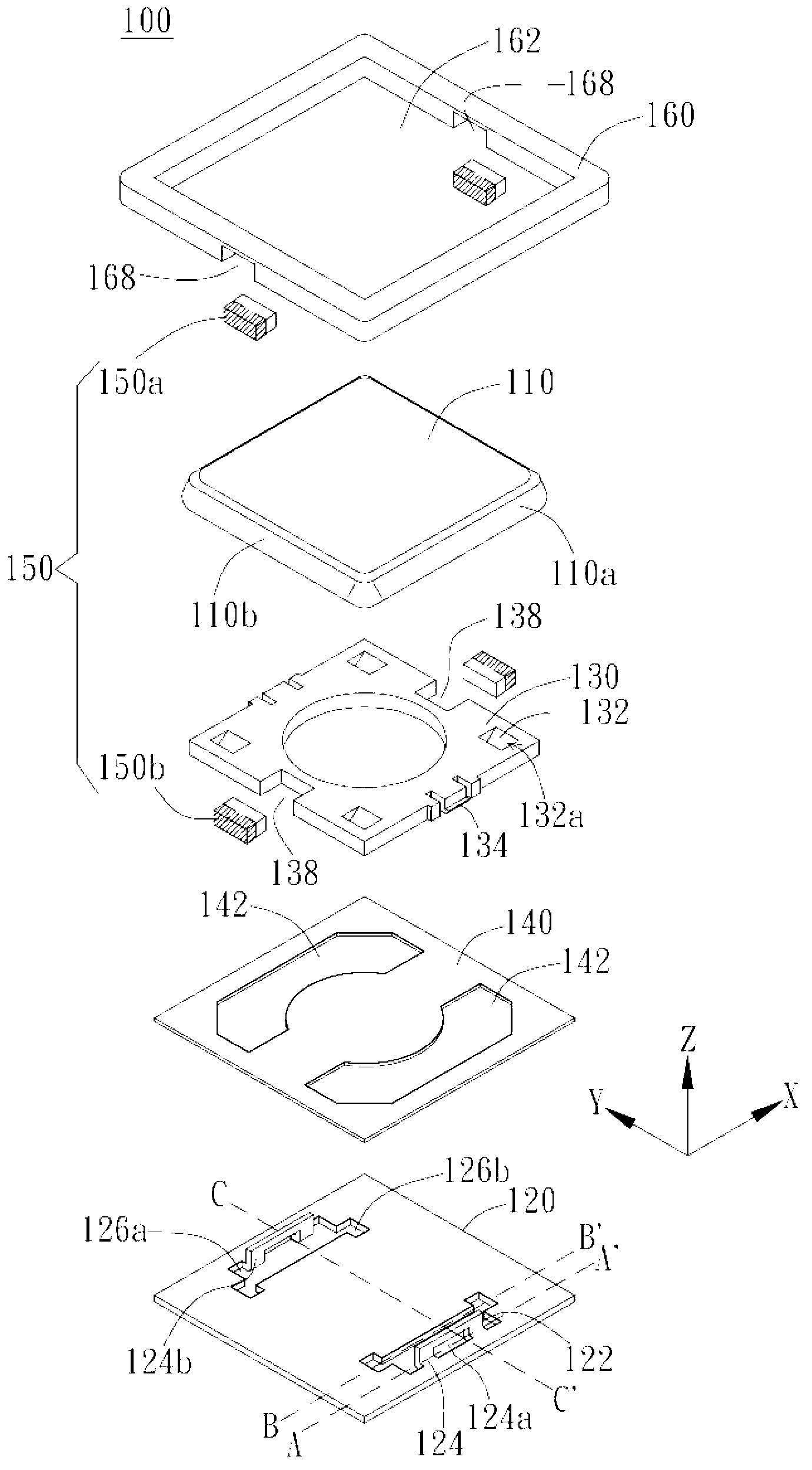

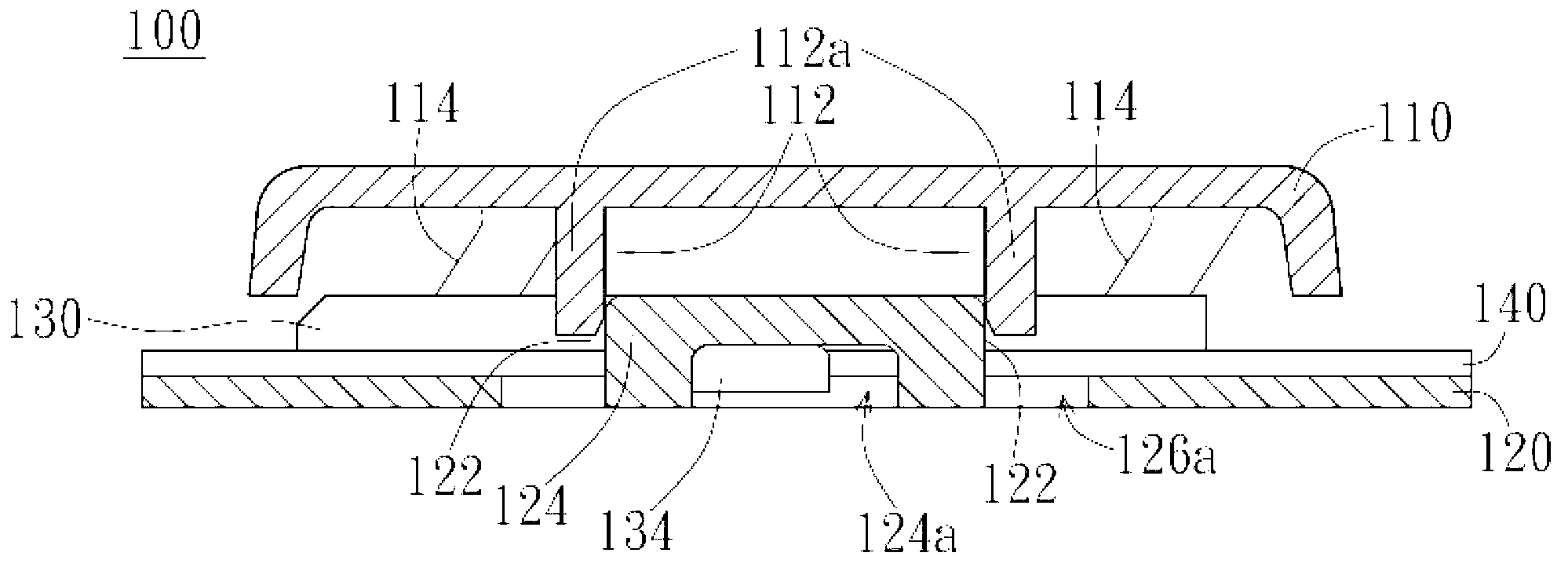

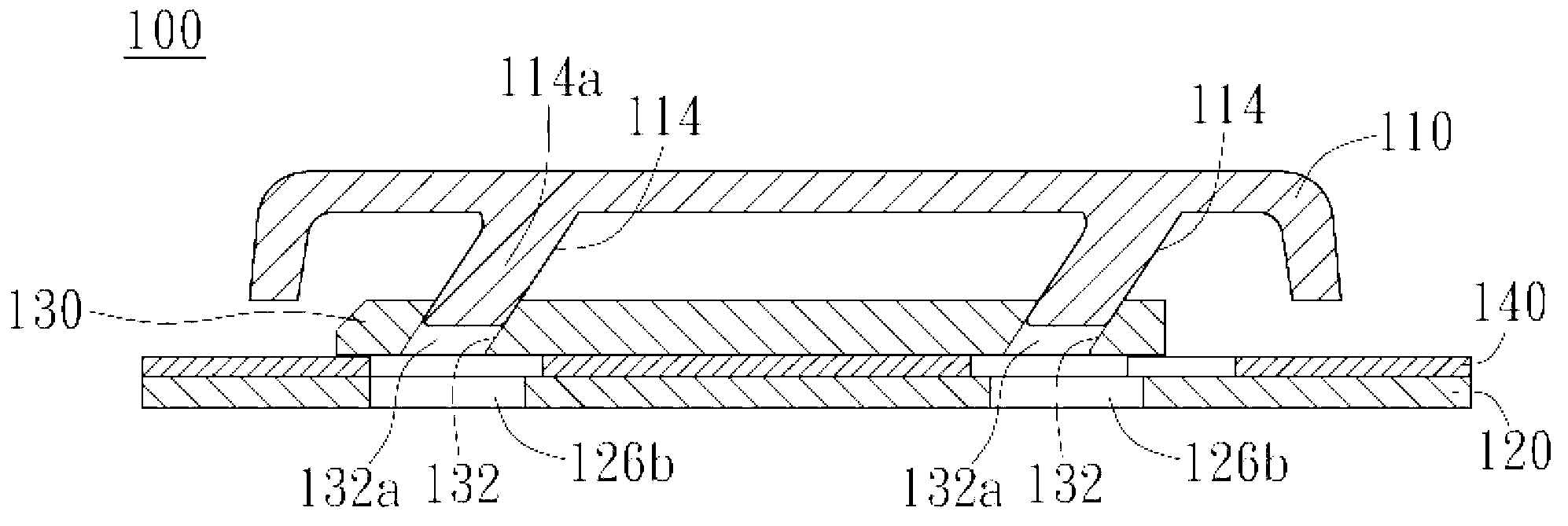

[0029] figure 1 It is an exploded view of the button structure according to an embodiment of the present invention, Figure 2A for along figure 1 The A-A' line is the cross-sectional view of the key structure after assembly, Figure 2B for along figure 1 The B-B' line is the cross-sectional view of the key structure after assembly, while Figure 2C for along figure 1 The C-C' line is the cross-sectional view of the key structure after assembly. like figure 1 and Figures 2A-2C As shown, the button structure 100 of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com