Calculation method for checking ultimate strength of fan underframe

A calculation method and technology of ultimate strength, applied in calculation, special data processing applications, instruments, etc., can solve problems such as the strength and safety of fan chassis, and achieve the effect of simple and easy calculation process, accurate force relationship, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

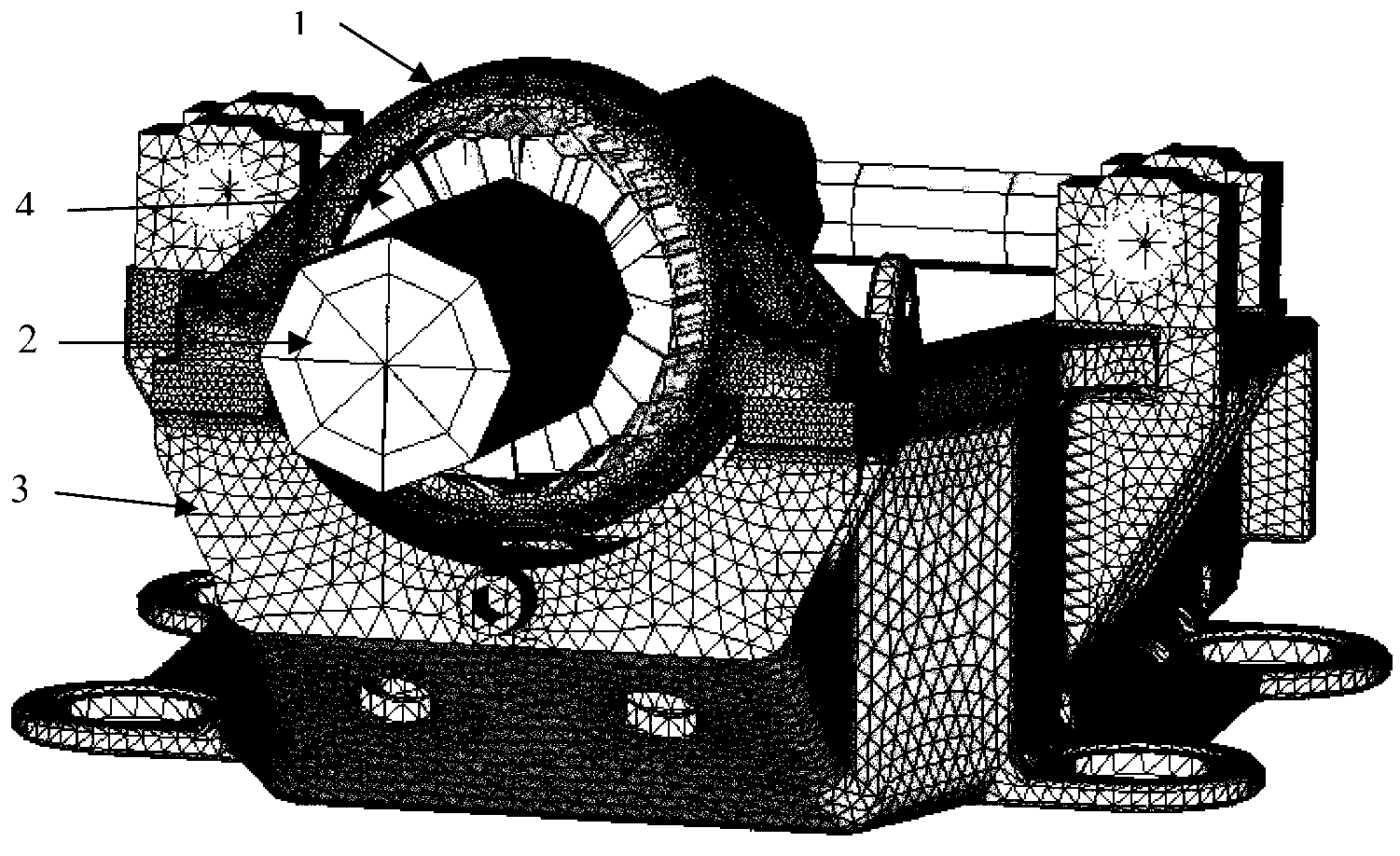

[0018] Embodiment: The calculation method of the present invention adopts ANSYS (finite element analysis software) as an implementation tool. This example is specifically described with the method of checking the ultimate strength of a fan chassis, as figure 1 As shown, its calculation method includes the following steps:

[0019] The first step: Establish the geometric model of the main shaft, chassis and main bearing: In the 3D software, establish the 3D model of the chassis and main bearing; use the beam element to establish the main shaft part.

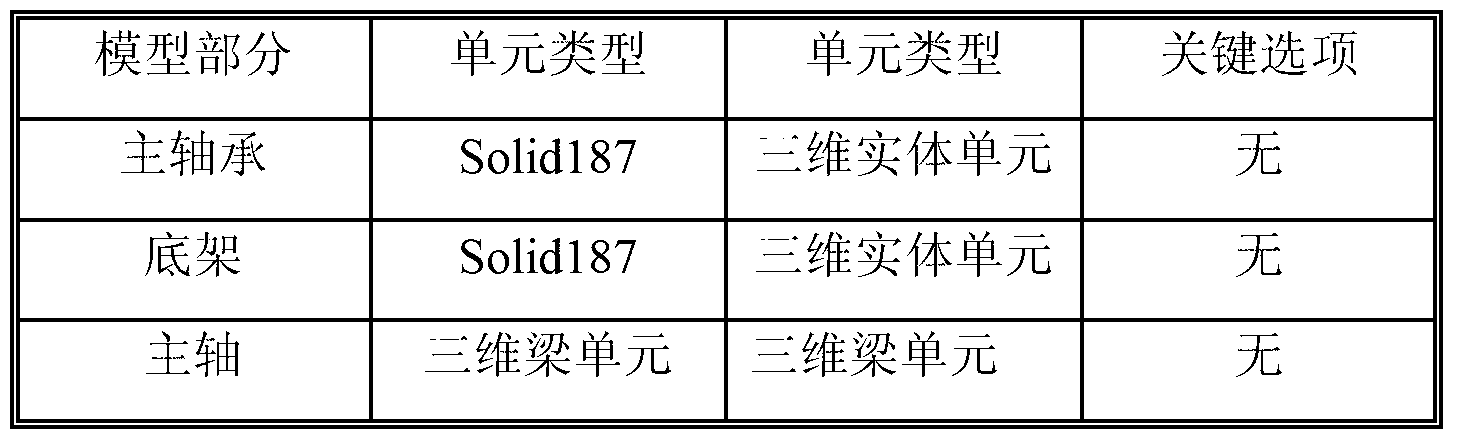

[0020] Step 2: Carry out finite element mesh division for the chassis and main bearing models: see Table 1 for details of the unit settings of each connecting part; use tetrahedron or hexahedron elements for mesh division, and at the same time, the unit size is 50-100mm; for Line elements are divided into three-dimensional beam elements, whose radius is the radius of the main axis. At the same time, each main axis is divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com