Pumping concrete cleaning divider and application method thereof

A technology for pumping concrete and diverter, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of threat to construction personnel, labor and time-consuming, and excessive waste, so as to improve safety and reduce environmental pollution. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

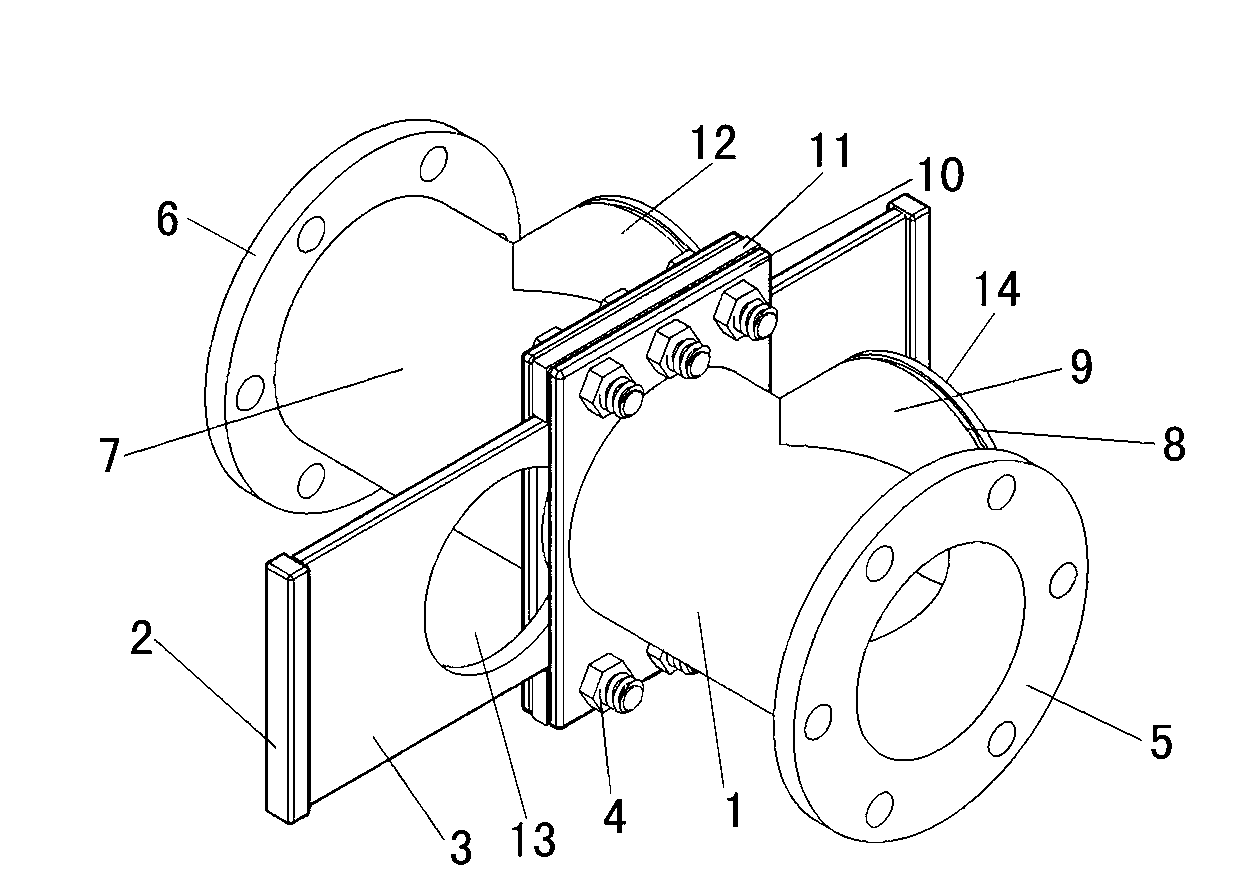

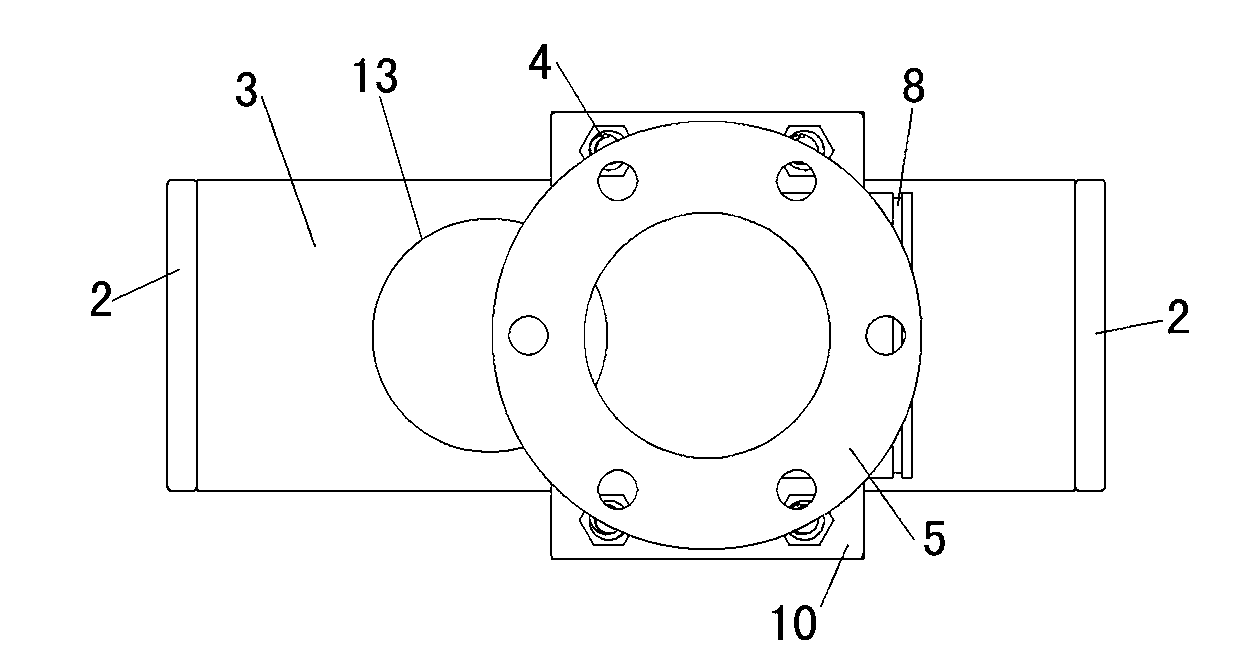

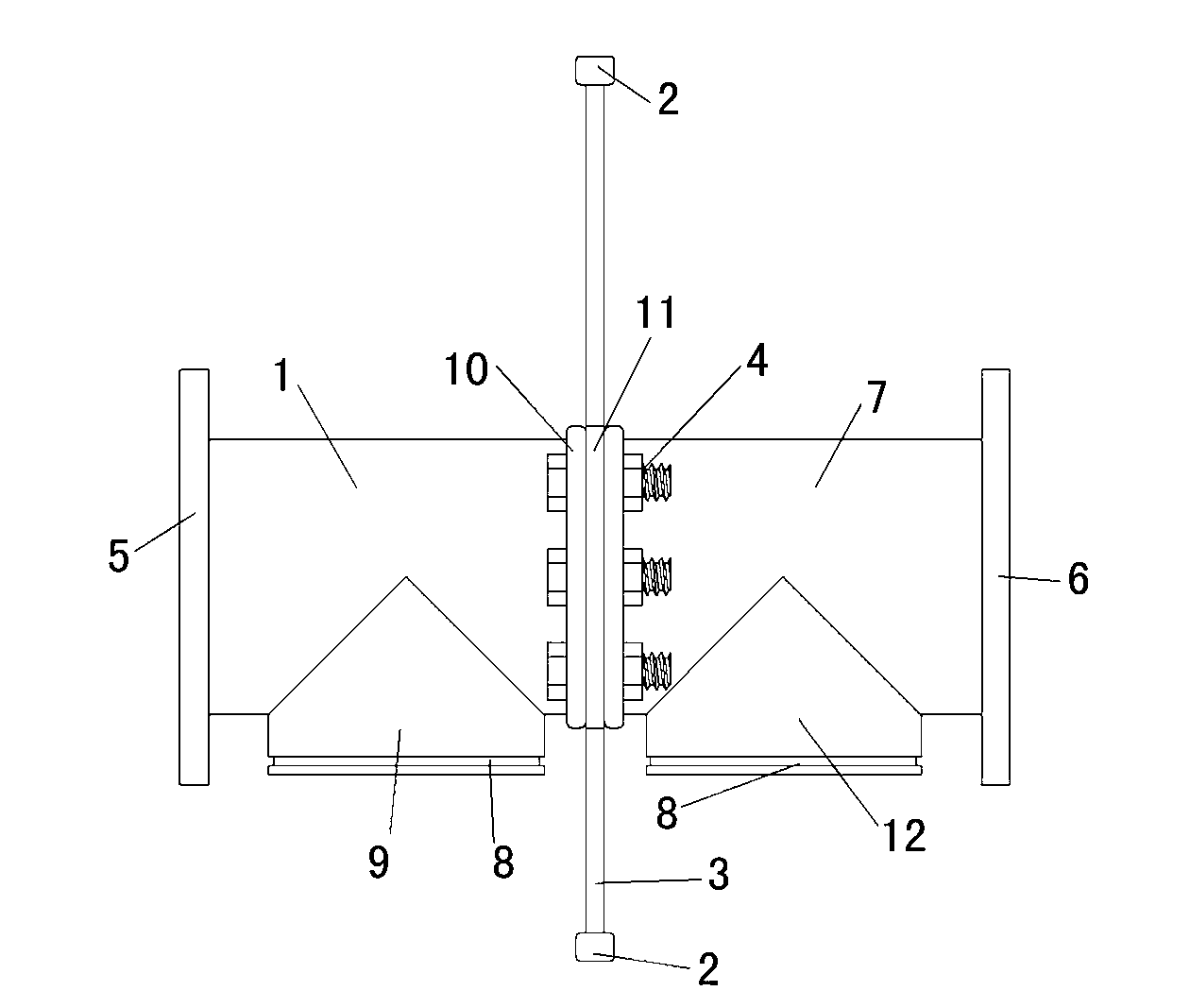

[0029] Examples see Figure 1-5 As shown, this pumping concrete cleaning splitter 18 (also referred to as splitter for short) is arranged on the outdoor pump pipe 17 (the pump pipe system includes the outdoor pump pipe 17, the indoor pump pipe 26 and the high-pressure concrete pump, and the outdoor pump pipe 17 communicates with the high-pressure concrete pump 16), including cleaning the diverter pipe body A1, cleaning the diverter pipe body B7 and the knife gate valve.

[0030] One end of the cleaning shunt body A1 is provided with a circular flange A5 connected with the outdoor pump pipe 17, and the other end of the cleaning shunt body A1 is connected with the square flange 10, the flange spacer 11 and the bolt 4. One end of the cleaning shunt body B7 is flanged, and the other end of the cleaning shunt body B7 is provided with a circular flange B6 for connecting with the outdoor pump pipe 17.

[0031] The pipe wall of the cleaning shunt body A1 is provided with a shunt outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com