Fiber extraction device and fiber multi-stage extraction device

An extraction device and fiber technology, which can be used in solid solvent extraction, textile and papermaking, and filament generation, etc., can solve the problems of a large number of godet rolls, a large extraction chamber volume, and difficulty in control, so as to increase the travel distance and reduce costs. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

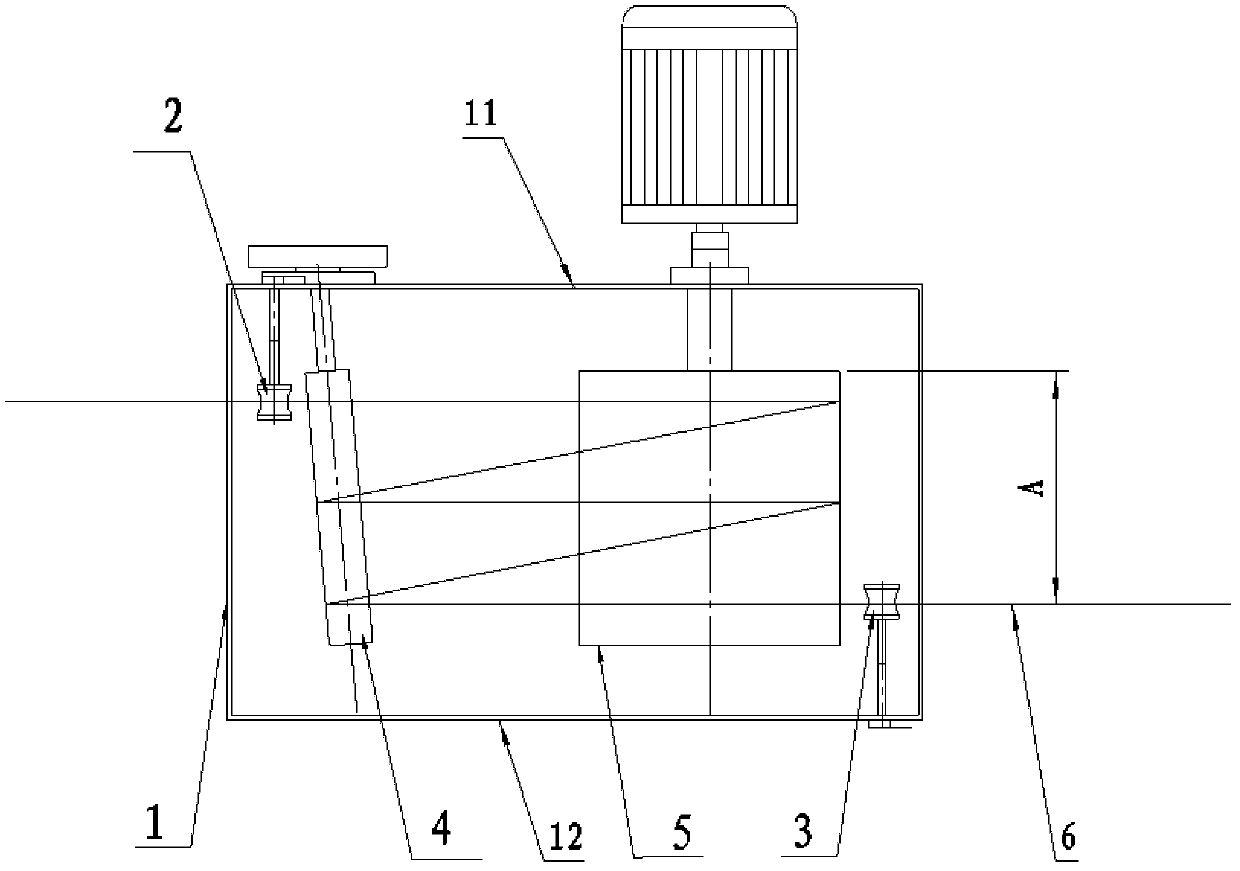

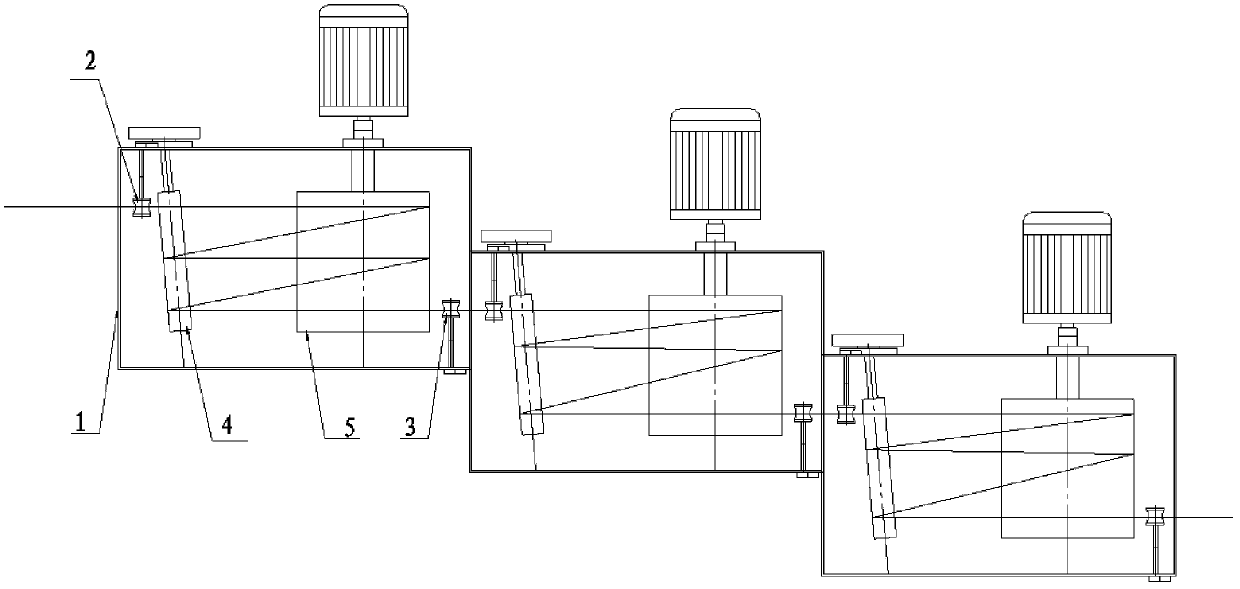

[0033] Such as figure 1 , the above-mentioned pair of guide wire rollers are respectively cylindrical or cylindrical equal-diameter rollers, and a pair of guide wire pair rollers are arranged in the extraction chamber, and the pair of guide wire pair rollers are the first roller 5 and the second roller 4, and the two rollers There is an included angle between the axes, and the included angle is an acute angle. In this way, the incoming wire will be automatically divided into multiple wire paths, so that the utilization rate of the godet rollers can be improved, and the amount of godet rollers can be reduced while achieving the same extraction effect. The volume of the extraction device reduces the cost, simplifies the structure, and increases the extraction bath ratio. Moreover, because the number of rollers is small, and the tension between the two can be automatically generated by the inclination angle, it is easy to control.

[0034] When in use, the extraction chamber 1 is...

Embodiment 2

[0044] In the above-mentioned embodiment 1, the second roller 4 can be disassembled to adjust the inclination angle, or in order to facilitate the adjustment of the angle between the two rollers, an angle adjustment device can be configured for the second roller 4, so that the second roller 4 can be adjusted without removing the second roller 4. angle.

Embodiment 3

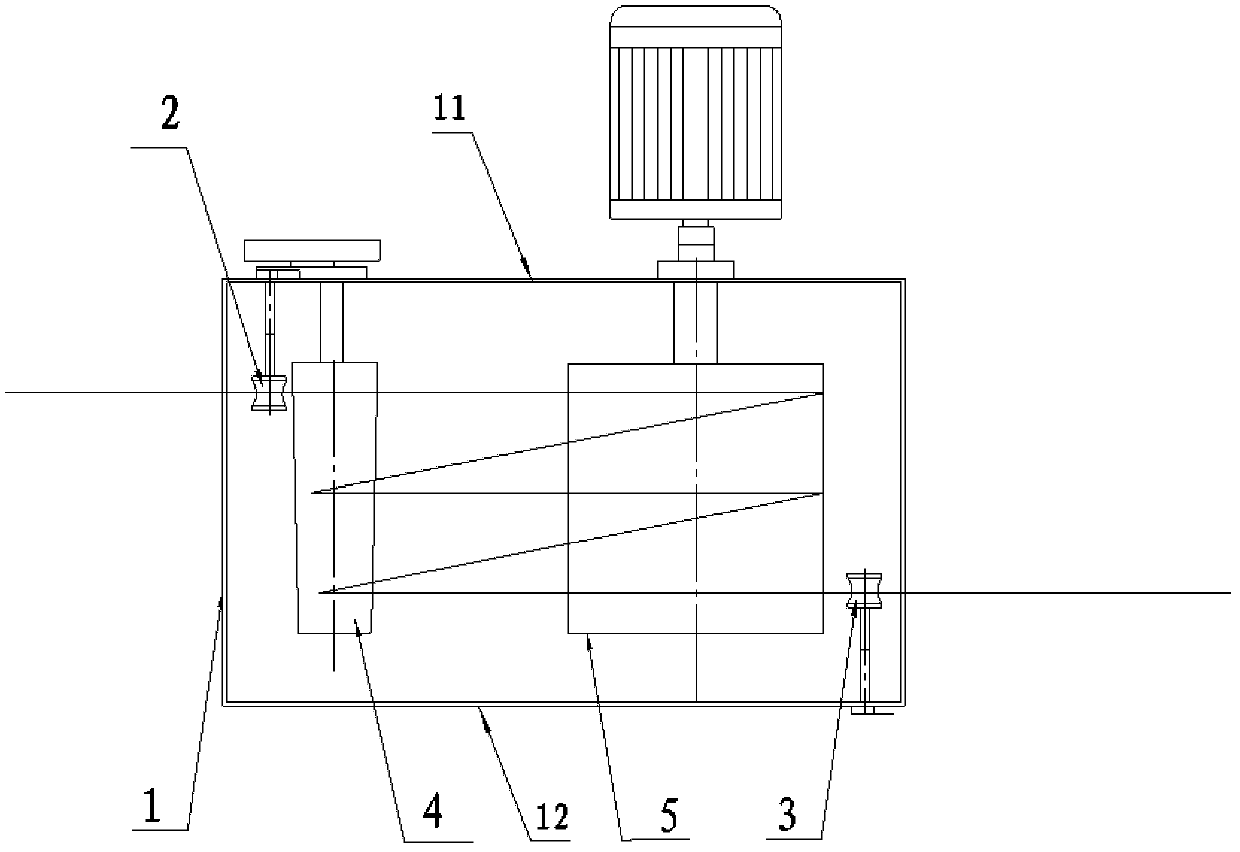

[0046] Different from Example 1, it can be as figure 2 Let the first roll 5 be an equal-diameter roll as shown, and the second roll 4 be a truncated conical roll, so that the distance between the two roll surfaces will gradually decrease from the installation end to the end. In this embodiment, there is no need to set an included angle between the two rollers, that is, the axes of the first roller 5 and the second roller 4 are parallel to each other, and the installation process is simpler.

[0047] Alternatively, the second roll 4 is an equal-diameter roll, the first roll 5 is a truncated conical roll, and the axes of the first roll 5 and the second roll 4 are parallel to each other.

[0048] The present invention mainly utilizes the principle that the distance from the installation end 11 of the extraction chamber to the end 12 of the extraction chamber on the outer edge of the rotating surface gradually decreases between the two godet rollers so that the fiber filaments ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com