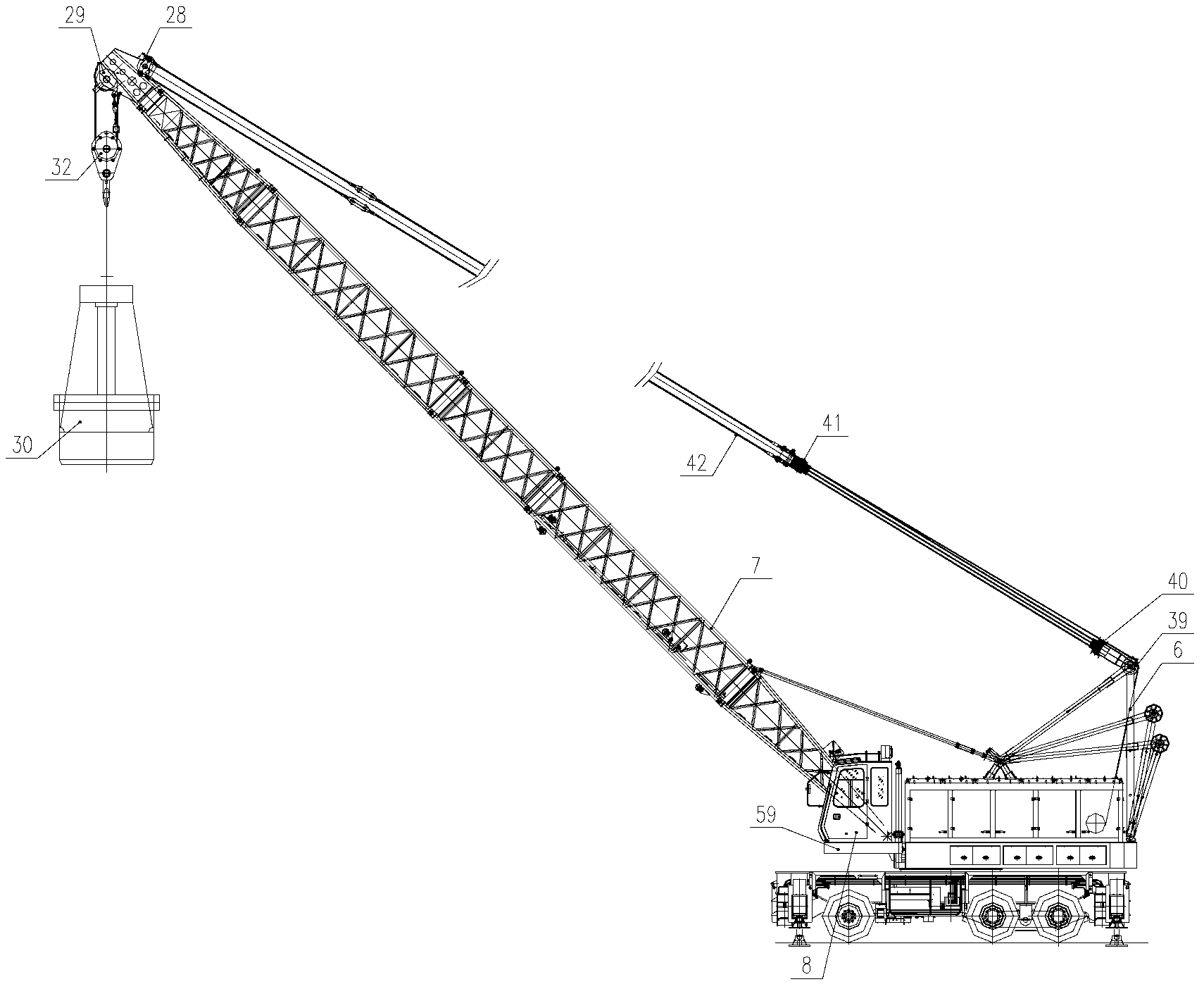

Multipurpose port tire crane

A tire crane, multi-purpose technology, applied in the direction of crane, clockwork mechanism, hoisting device, etc., can solve the problems of limited lifting capacity, single function, low efficiency, etc., to improve the utilization rate, expand the scope of work, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

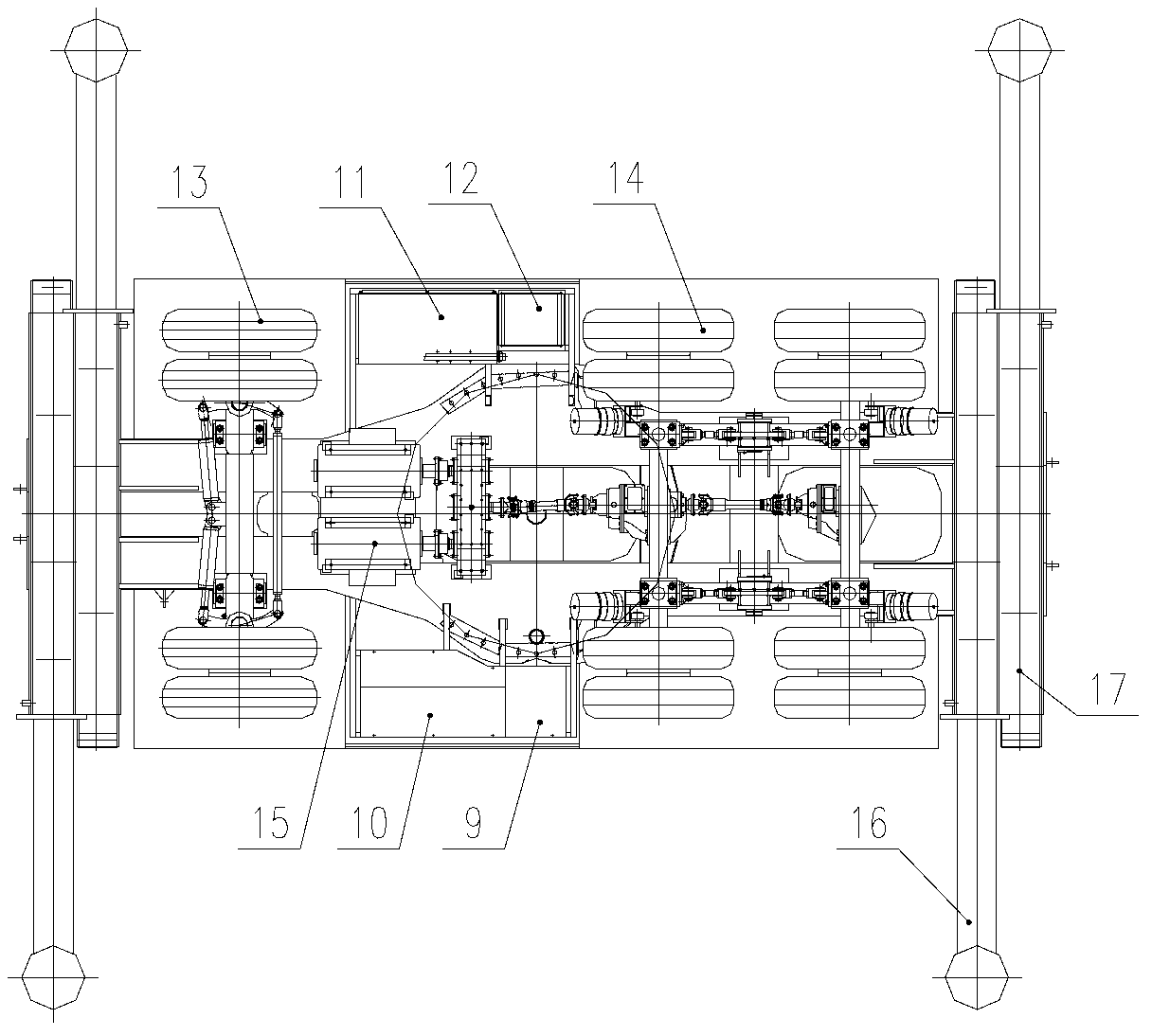

[0030] see Figure 1-7 , a multi-purpose port tire crane, which includes a lifting mechanism 1, a turntable 2, an internal combustion engine 3, a luffing mechanism 4, a slewing mechanism 5, a herringbone frame 6, a jib frame 7, a driver's cab 8, a driving control cabinet 9, and a cable Reel or cable box 10, hydraulic pump station 11 and multi-way valve 12, steering axle 13, drive axle 14, traveling mechanism 15, movable outrigger 16, fixed outrigger 17 and underframe, in which the hoisting mechanism, luffing Mechanism, slewing mechanism, herringbone frame, arm frame, internal combustion engine and driver's cab are arranged on the turntable above the bottom frame; driving control cabinet, cable reel or cable box, hydraulic pump station and multi-way valve are arranged on the bottom frame; The bridge, drive axle and running mechanism are arranged on the underside of the chassis, and the movable outriggers are arranged in the fixed legs on the chassis; the lifting mechanism is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com