Manufacturing equipment and process of woven embroidery thread color card

A technology for manufacturing equipment and embroidery threads, applied in the field of manufacturing woven embroidery thread color card equipment and its process, can solve the problems of easy winding loose, affecting color matching, falling off, etc. The effect of high degree and regularity, not easy to fall off and loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

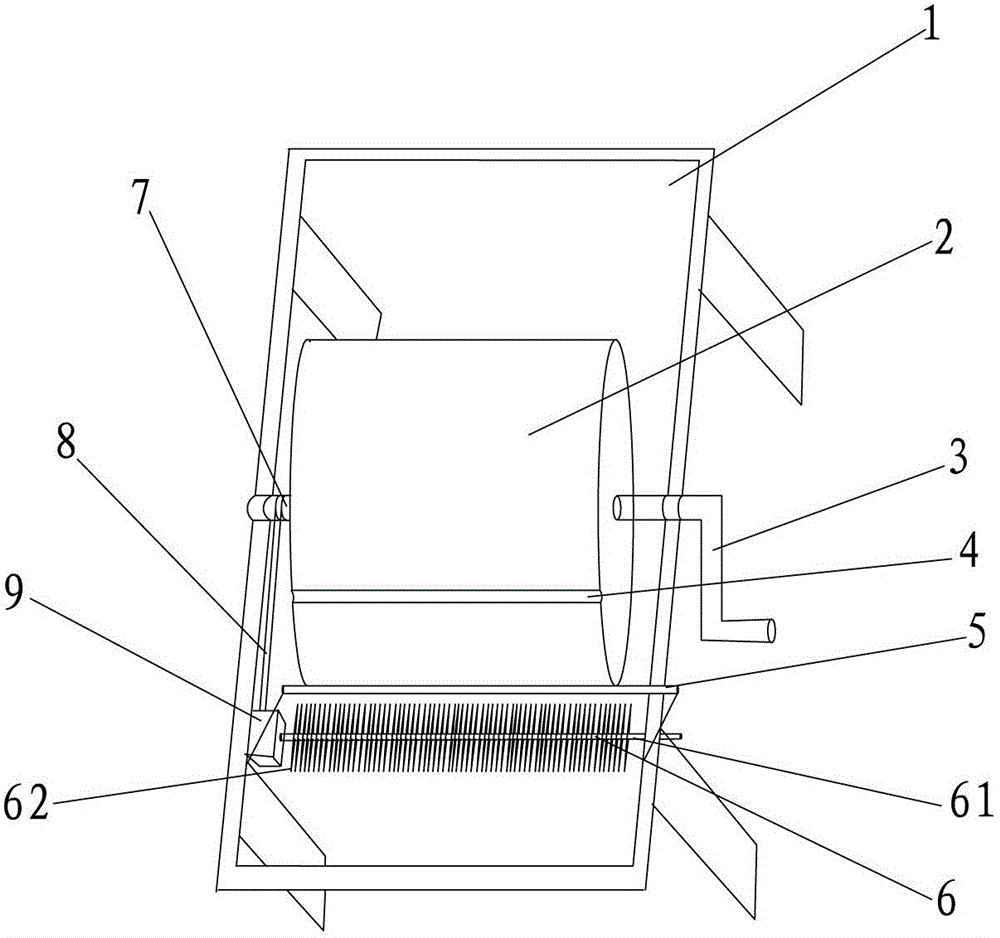

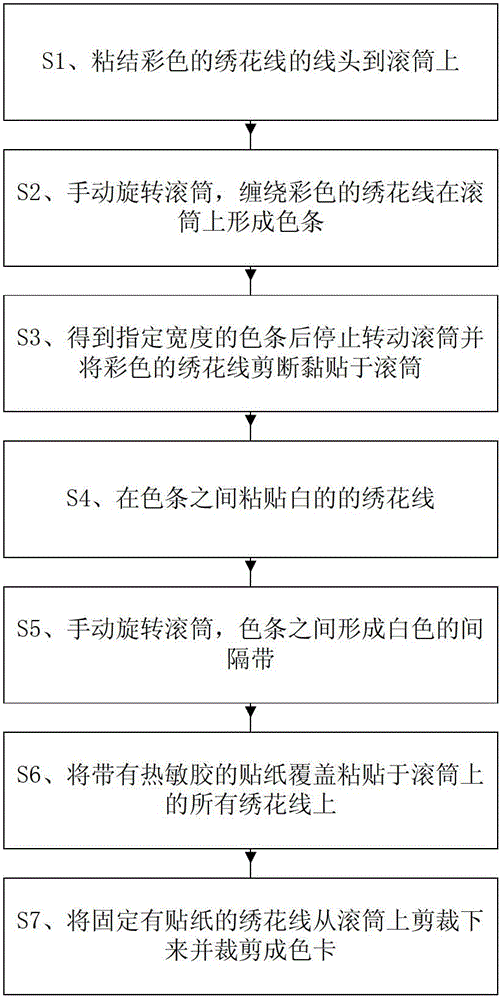

[0028] see figure 1 , a kind of braided embroidery thread color card manufacturing equipment in this embodiment, including a support 1, a roller 2, a branch, an interval controller 6 and a thread rack (not shown in the figure); the interval controller 6 includes a cross bar 61, the crossbar 61 is pivotally connected to the bracket 1, and a plurality of protruding teeth are arranged at intervals on its side; the thread rack is used to place embroidery thread, and the embroidery thread is connected to the cylinder 2 through the interval controller 6; the cylinder 2 Pivoted on the bracket 1, one end of which is provided with a rocker arm 3, the rocker arm 3 drives the drum 2 to rotate along the pivot axis; The end is provided with a pivot sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com