Runner screw guide type drive impeller

A runner and screw technology, applied in propellers, rotating propellers, transportation and packaging, etc., can solve the problems of hindering high-speed driving, upper limit, resistance shock wave, etc., and achieve the effect of changing energy consumption and increasing the upper limit of driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

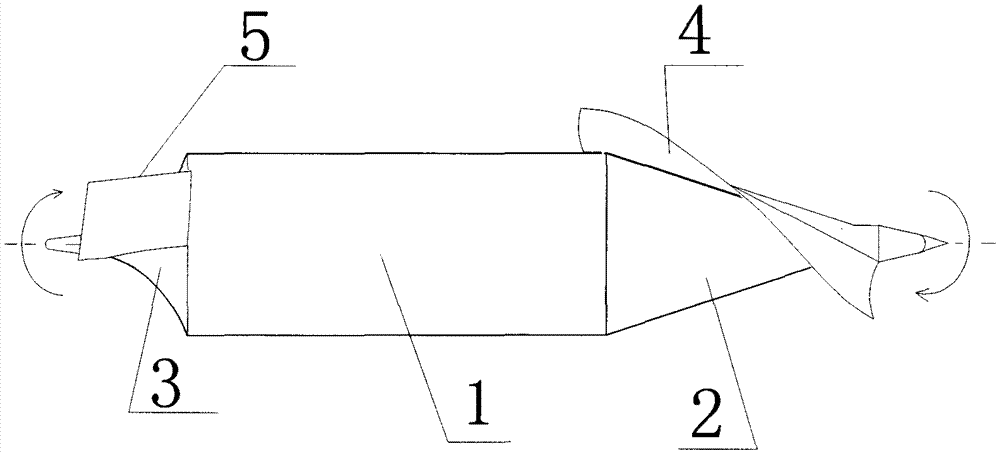

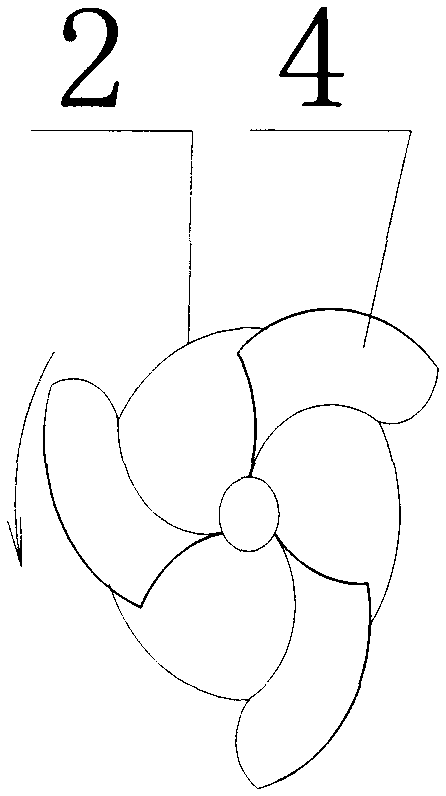

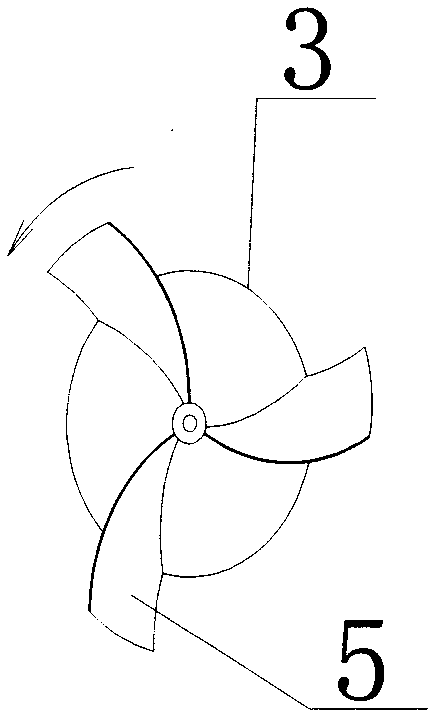

[0017] The present invention is a spiral pressure-guided driving impeller for a runner, which includes a runner 1 and a front impeller 2; the front impeller 2 for dredging the pressure generated by the external medium due to the speed is installed on the outside of the front cone of the runner 1, The front blade 4 is installed on the front impeller 2 outside the front vertebral body of the runner 1. The front blade 4 is spirally arranged on the cone surface of the front impeller 2. The front end of the front blade 4 is biased to the direction of rotation, and the surface of the front blade 4 is groove-shaped. , the direction of the groove faces the direction of rotation of the front impeller 2, the line connecting the inner and outer edges of the front blade 4 is perpendicular to the axis of the runner 1, the shape of the front blade 4 is twisted, and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com