Mining electric locomotive leak-proof automatic stuccoing device

A technology of sand spreading device and electric locomotive, which is applied to locomotives and other directions, can solve the problems of high manufacturing cost, inconvenient operation, complex structure, etc., and achieves the effects of low cost, simple and reliable structure, and prevention of sand falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

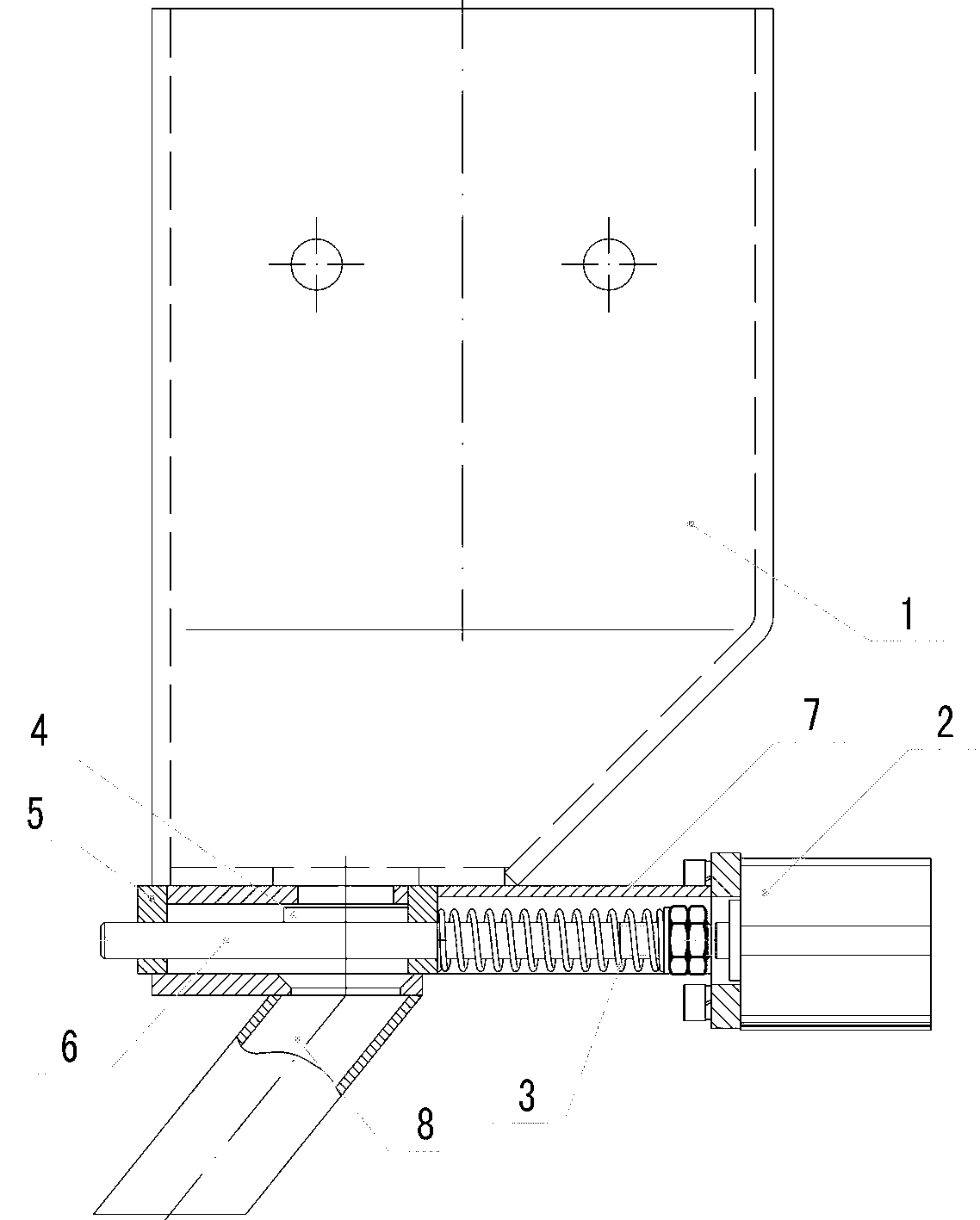

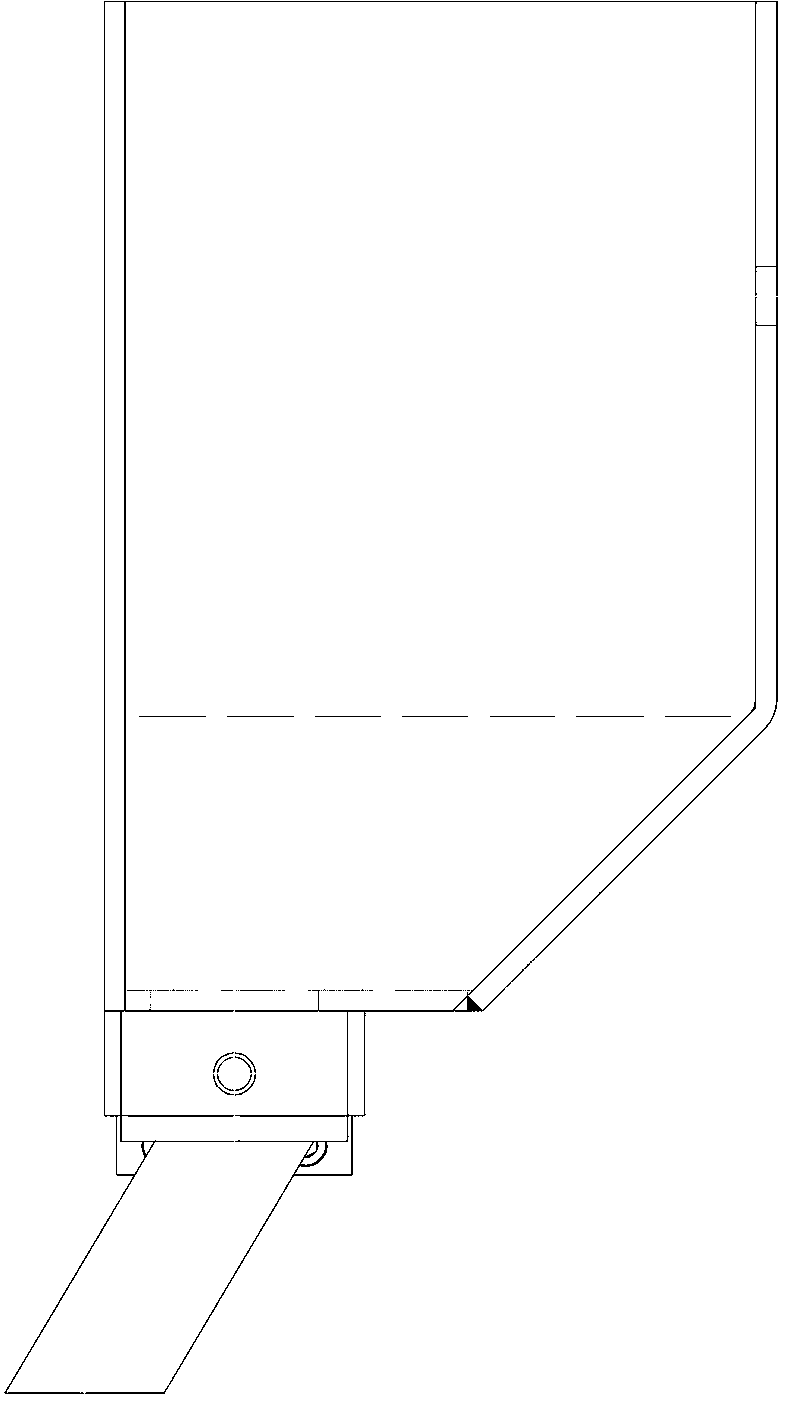

[0014] Embodiment 1, the present invention comprises sand box 1, sealing plate 4, and the bottom plate of sand box 1 is joined with the top plate of sand spreading box 5 and the top of one side of power unit support plate 7, and the other side of power unit support plate 7 It is fixedly connected with the power device 2 to make the structure more stable. Under the support plate 7 of the power device, the side of the power device 2 is fixedly connected with the spring 3, and the inner side of the spring 3 surrounds the power device connected with the power device 2 and crosses the sand box 5. Axis 6 and spring 3 are fixedly connected with the side plate of sand spreading box 5, and the control effect can be achieved by advancing power device 2 and resetting spring 3. Power shaft 6 is fixed with a circular outlet on the top plate of sand spreading box 5. Sealing plate 4, power shaft 6 motions can drive sealing plate 4 motions, reach the effect of controlling sand spreading, and s...

Embodiment 2

[0015] Embodiment 2, the upper part of the sand box 1 of the present invention is a cuboid, and the lower part is a square cone-shaped funnel. The middle part of the bottom plate of the sand box 1 is provided with a circular through hole, so that the sand automatically gathers and flows out to the bottom. refer to Figure 1 to Figure 3 , all the other are with embodiment 1.

Embodiment 3

[0016] Embodiment 3, the power device (2) of the present invention adopts a pneumatic device, which is safer and more reliable. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com