Full-automatic splicing type box machine and method for processing packing boxes

A fully automatic, box-making machine technology, used in packaging, transportation and packaging, container manufacturing machinery, etc., can solve problems such as unresolved technical defects and fast drying of carton glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

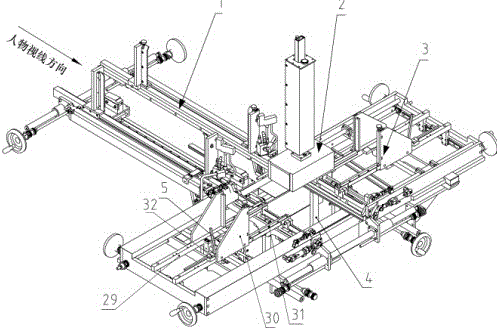

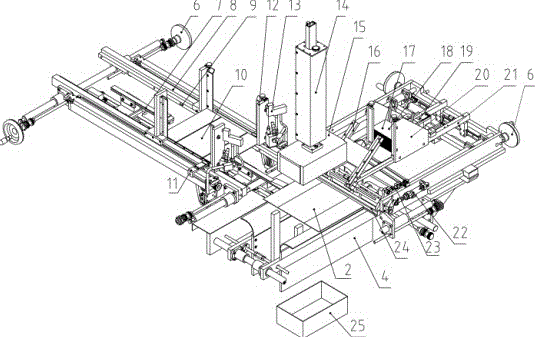

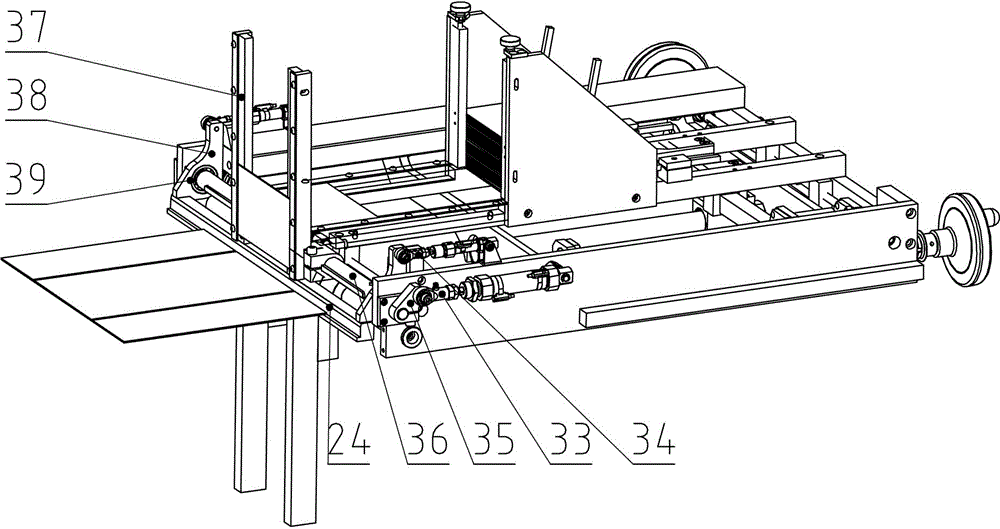

[0175] figure 1 It is a schematic layout diagram of a preferred embodiment of the present invention, figure 2 for the invention figure 1 Schematic diagram of the structure of the illustrated embodiment. Such as figure 1 and figure 2 As shown, a fully automatic jigsaw box-making machine includes a bottom plate conveying and spraying station, the output end of which is connected to the bottom plate input end of the product forming station, and the product forming station has left and right sides Plate input end, which is respectively connected with the output end of the left side plate conveying vertical plate station and the right plate conveying vertical plate station, wherein, the left plate conveying vertical plate station is provided with a left vertical plate mechanism, so The right vertical board station is provided with a right vertical board mechanism, and the bottom board conveying and spraying station is provided with a guide groove, which includes a support ...

Embodiment 2

[0177] A fully automatic jigsaw box-making machine, the same as embodiment 1, the difference is that the guide rail pair is a closed linear guide rail.

Embodiment 3

[0179] A fully automatic jigsaw box-making machine, the same as the embodiment 1, the difference is that the synchronous belt is a double-sided toothed belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com