A mold for preparing radial columns of permanent magnetic materials and its application method

A permanent magnet material and radial column technology, applied in the field of magnetic material manufacturing, can solve the problems of uneven density of green compacts, long isostatic pressing time, large deviation of magnetic field poles, etc. The effect of uniform magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

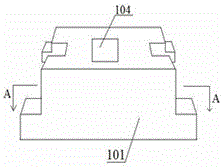

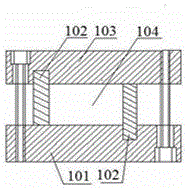

[0031] The present invention will be further described below in conjunction with accompanying drawing.

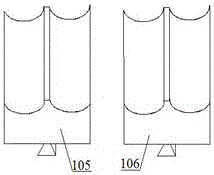

[0032] Such as Figure 4 , Figure 5 with Image 6 As shown, a mold for preparing radial columns of permanent magnetic materials includes a main template II201, a secondary template II207, an upper indenter II209, and a lower indenter II210. The main template II201 and the auxiliary template II207 are fastened and connected by screws I202. The middle block 206, the center of the middle block 206 is provided with not less than two circular cavities 205, the two ends of the middle block 206 are provided with protrusions 204, the main template II 201 and the secondary template II 207 are U-shaped grooves 208 are formed symmetrically, and the protrusions 204 are installed in the U-shaped grooves 208 respectively.

[0033] Preferably, two screw holes are symmetrically opened at both ends of the U-shaped groove 208, and screw holes corresponding to the screw holes of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com