Artificial bone joint friction and abrasion test device

A friction and wear test, artificial bone technology, applied in the field of instrument science or bionic robot, can solve the problems of friction and wear test, unable to carry out joint pair, unable to effectively simulate the shutdown of human body, etc., to achieve the effect of accurate and reliable experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

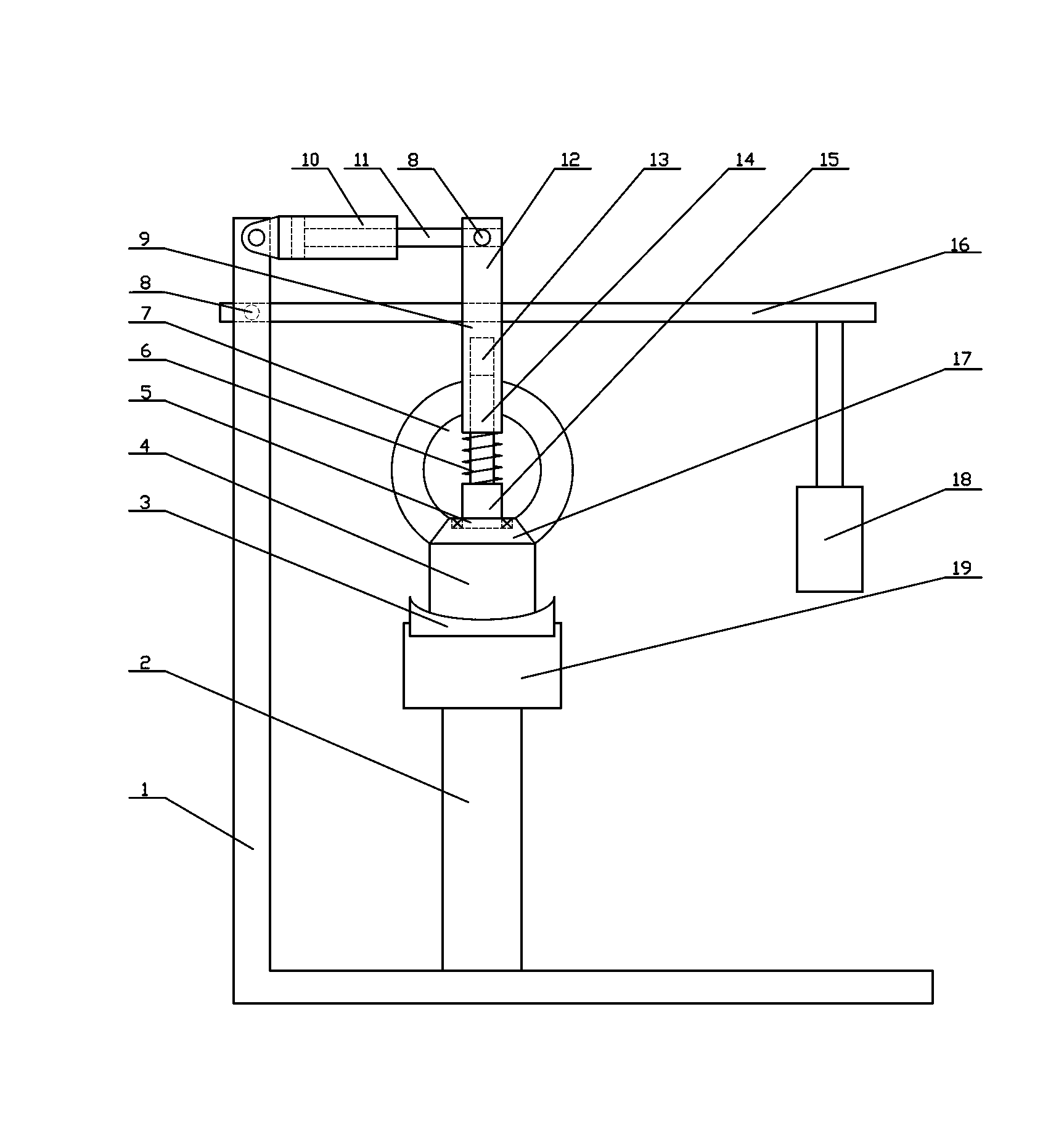

[0014] Attached below figure 1 The present invention is described further:

[0015] A friction and wear test device for artificial bone joints, comprising a base 1, the base 1 is "L" shaped, the top of the base 1 is fixedly provided with a cylinder 10, the piston rod 11 of the cylinder 10 is provided with a push rod 9, the The push rod 9 is vertically placed, the rear portion of the push rod 9 is fixedly provided with a first bevel gear 7, and the bottom surface of the push rod 9 is provided with a second bevel gear 17 meshing with the first bevel gear 7, The push rod 9 is concentric with the second bevel gear 17, and the second bevel gear 17 is provided with a rolling bearing 5, the push rod 9 and the second bevel gear 17 are connected together through the rolling bearing 5, The lower part of the second bevel gear 17 is fixedly provided with a joint head 4 , and the lower part of the joint head 4 is provided with a joint socket 3 fixedly provided on the base 1 .

[0016] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com