Swivel with or for hydrant manifold industrial fire fighting

A hydrant water separator and fire-fighting technology, which is applied in the field of rotary fire hydrant water separators, can solve the problems of increased waste costs and increased diameter requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

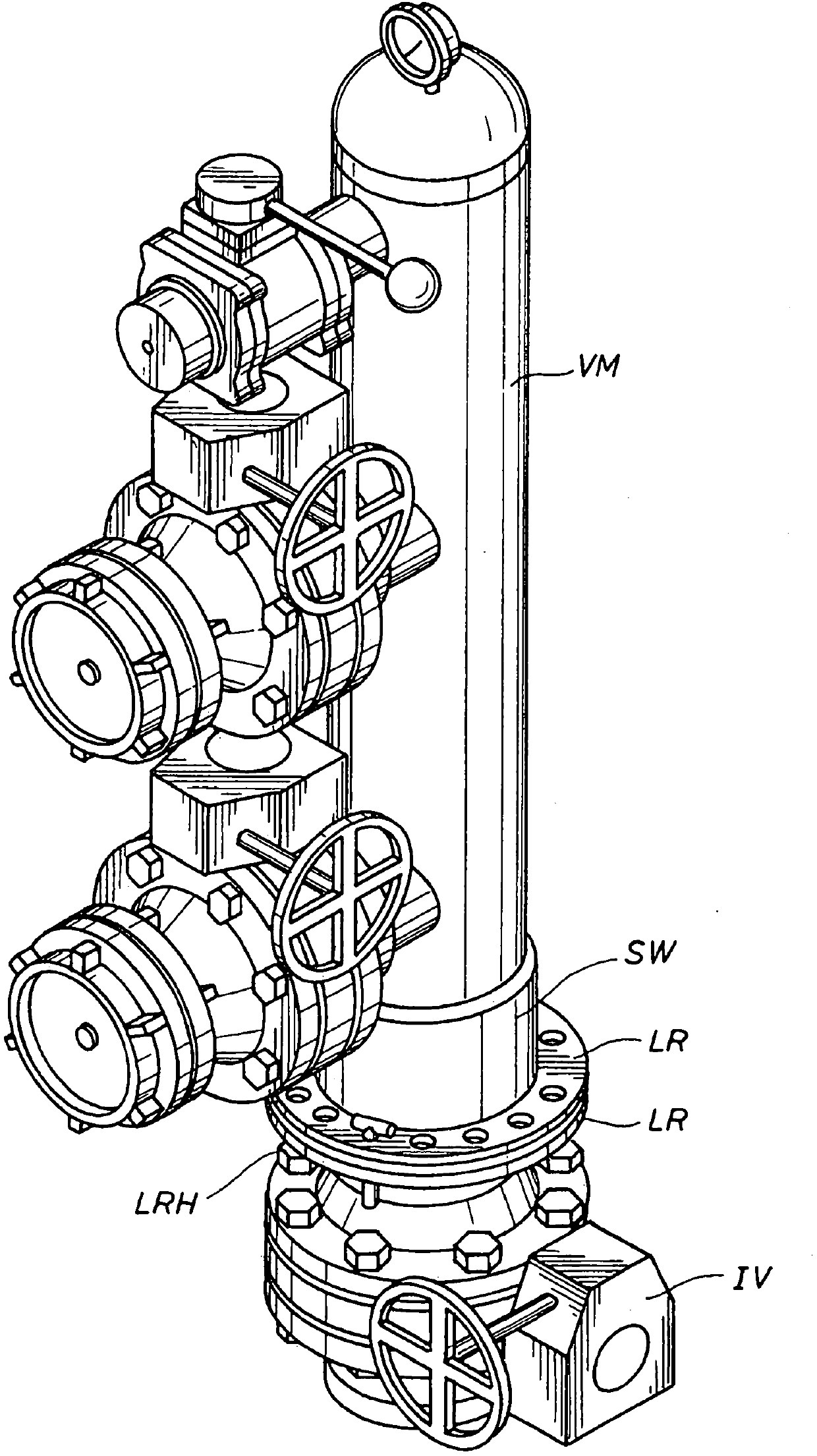

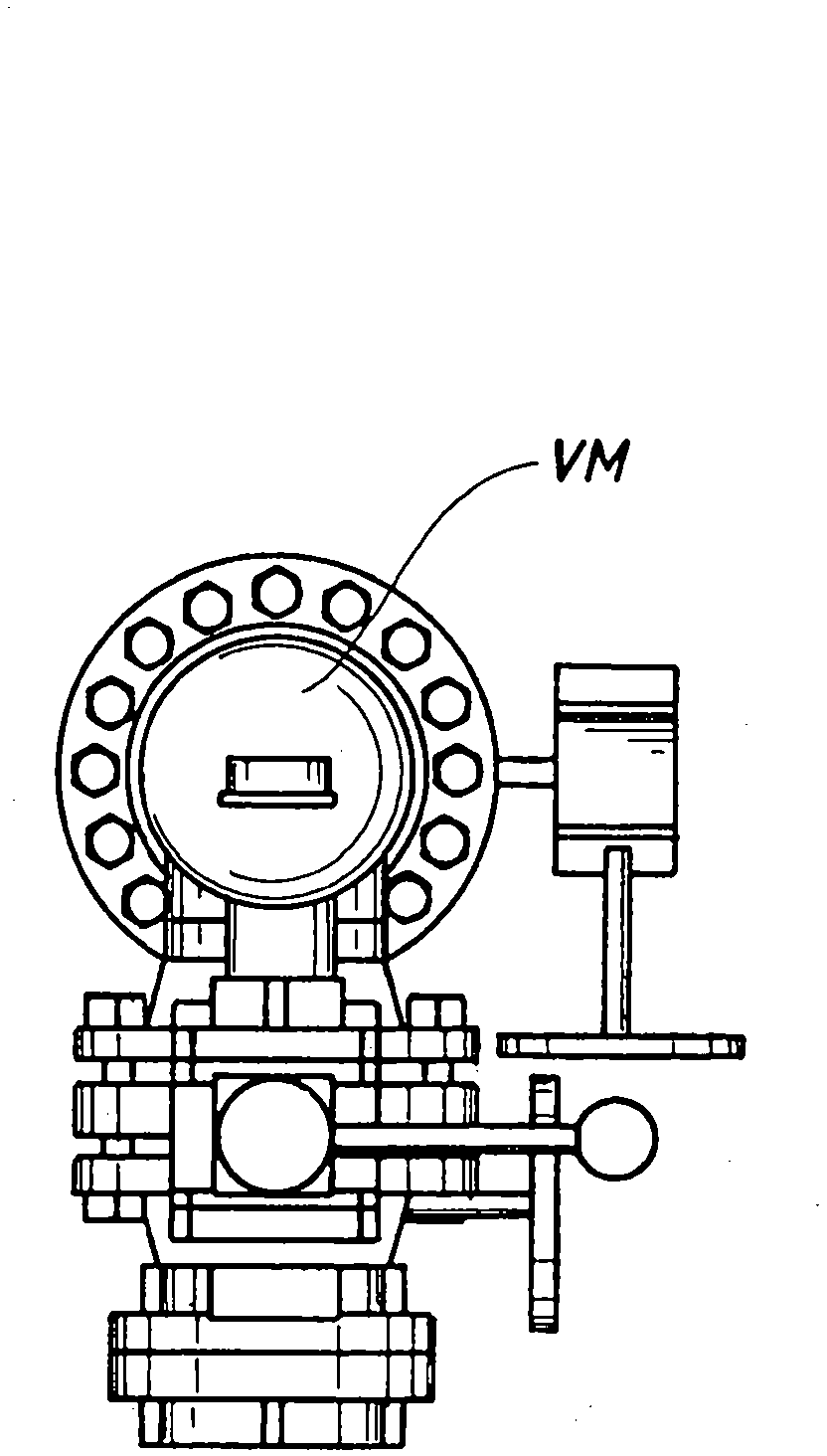

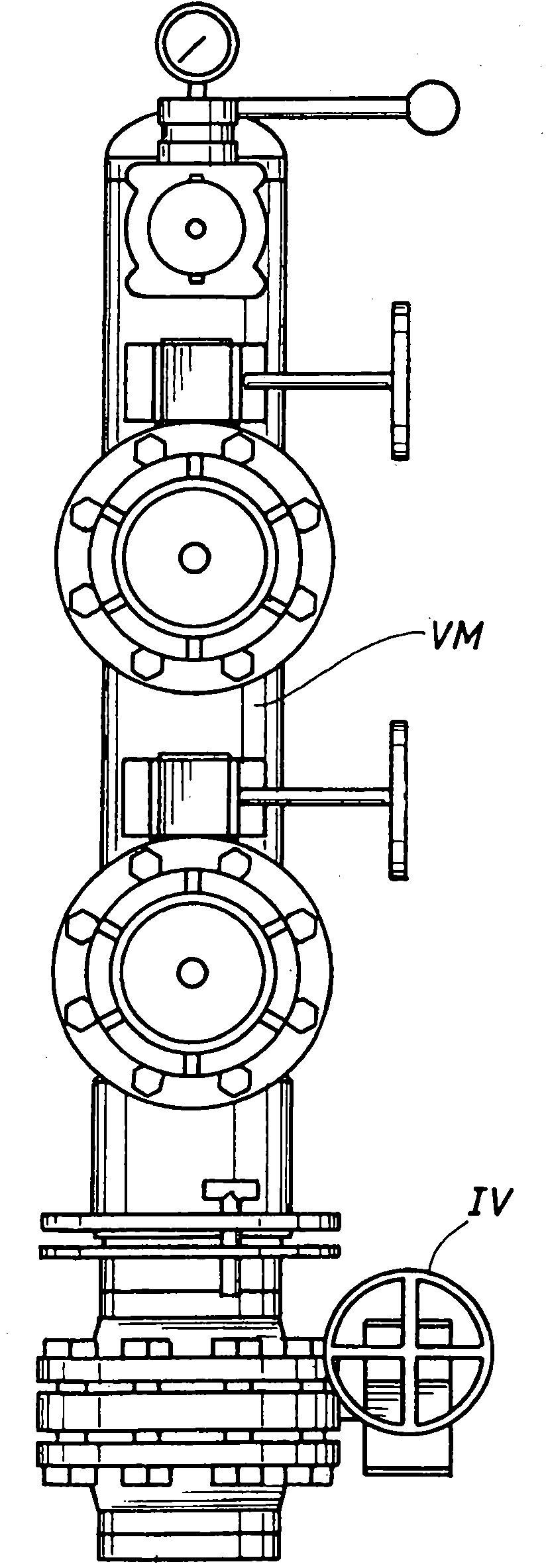

[0084] As shown in Figures 1-8, the preferred swivel embodiment of the present invention includes 316 stainless steel sleeves FS and MS and ball bearings SB. Stainless steel sleeves are preferably heat treated and annealed. In a preferred embodiment, the races RSSB of the bearing rings for at least two ball bearings SB are ground, half forming a female sleeve FS and half forming a male sleeve MS, wherein in the female The sleeve is provided with a port P for insertion of the ball bearing SB. Preferably at least one grease nipple GF is provided to maintain proper lubrication of the area between male MS and female sleeve FS and around ball bearing SB.

[0085] An external debris seal location DSL is preferably provided for a debris seal, such as an O-ring, which is provided in a suitable notch between the male and female bushings. In a preferred embodiment, a simple O-ring has been shown to prevent debris from entering the area between the male and female sleeves from the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com