A method for applying a film on moulded fibrous product and a product produced by said method

A fiber product and product technology, applied in the field of suction molds, which can solve the problems of film rupture, bubble formation, high discard rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

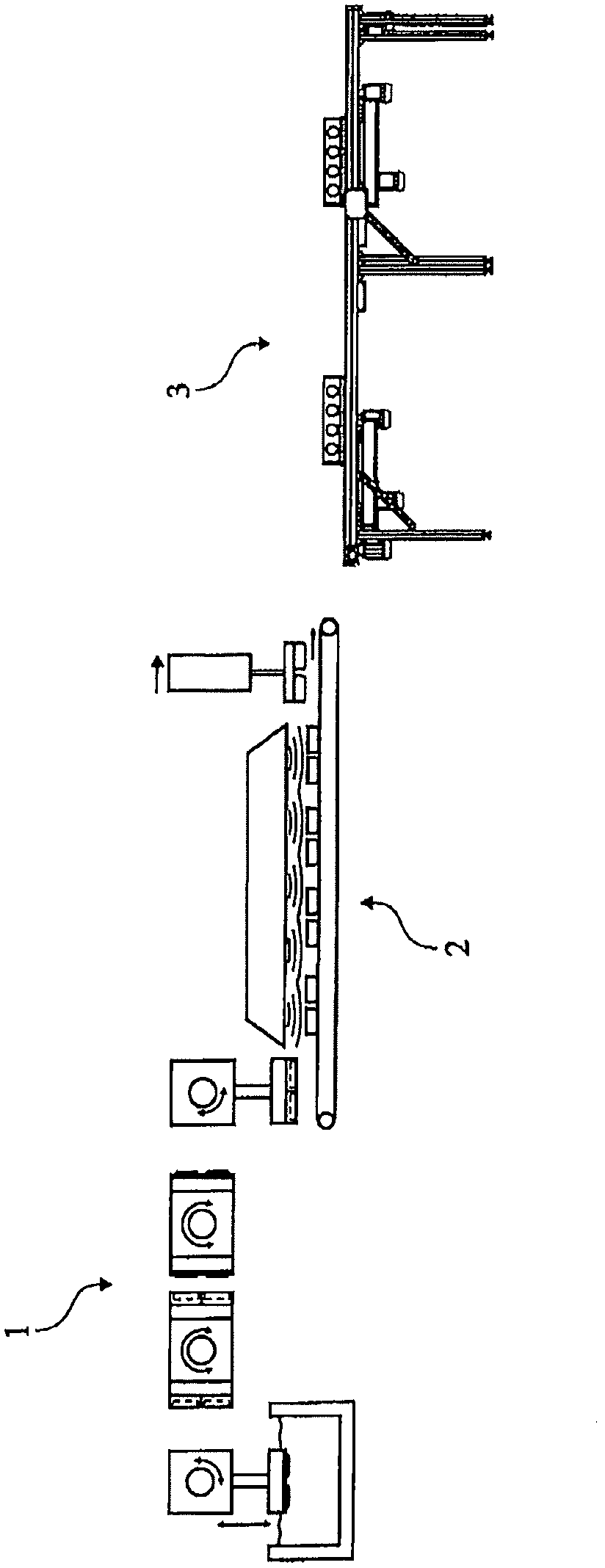

[0033] figure 1 is a schematic diagram of a manufacturing process for making molded fiber products, illustrating a forming section 1 for forming a molded pulp product, a drying section 2 for drying the molded pulp product, and a drying section for drying the molded pulp The post-processing part 3 where the product is subjected to post-processing steps such as trimming the edges of the pulp product, baling the pulp product, etc. The film is preferably applied to the product before or during the post-processing part 3 when the product is substantially dry.

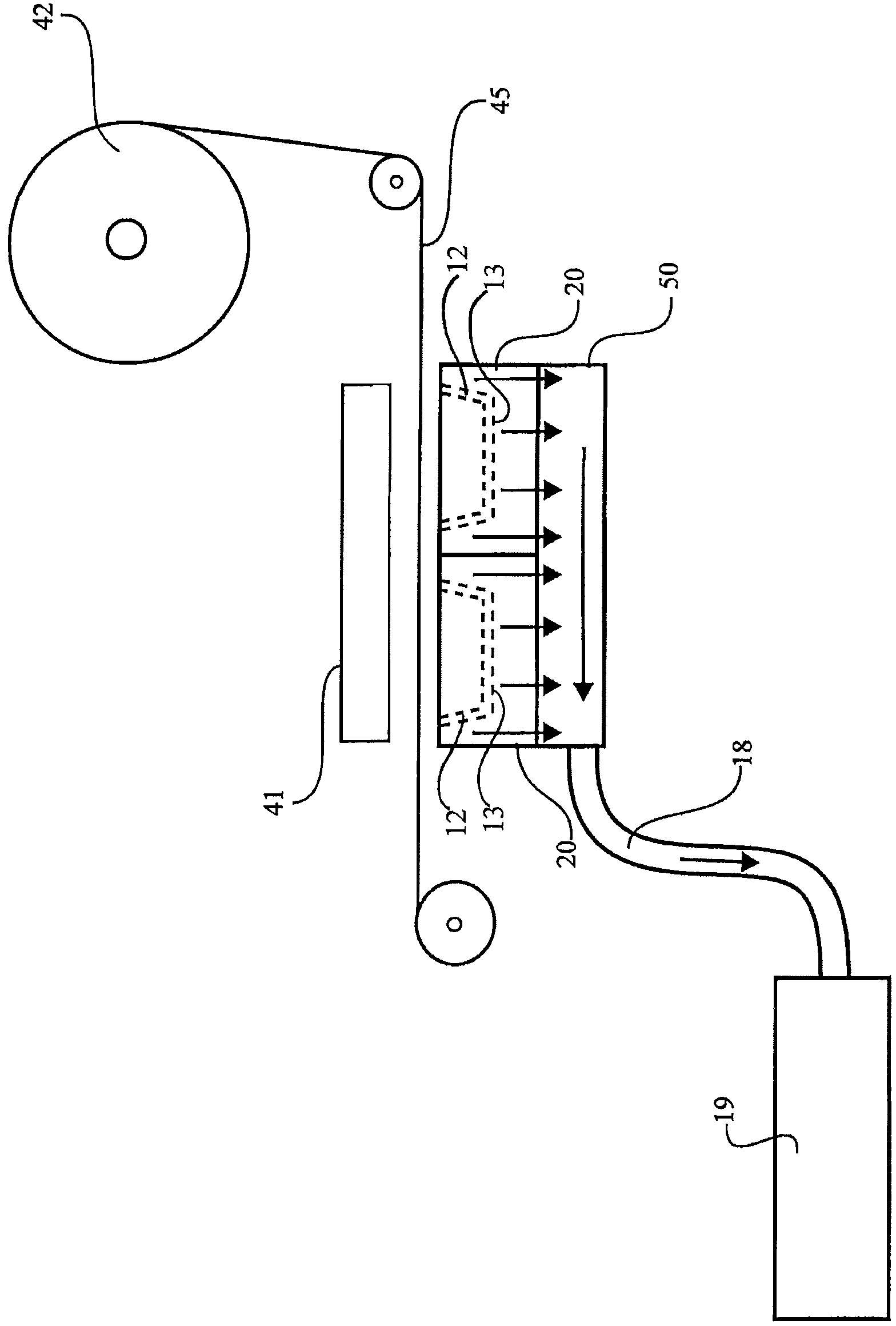

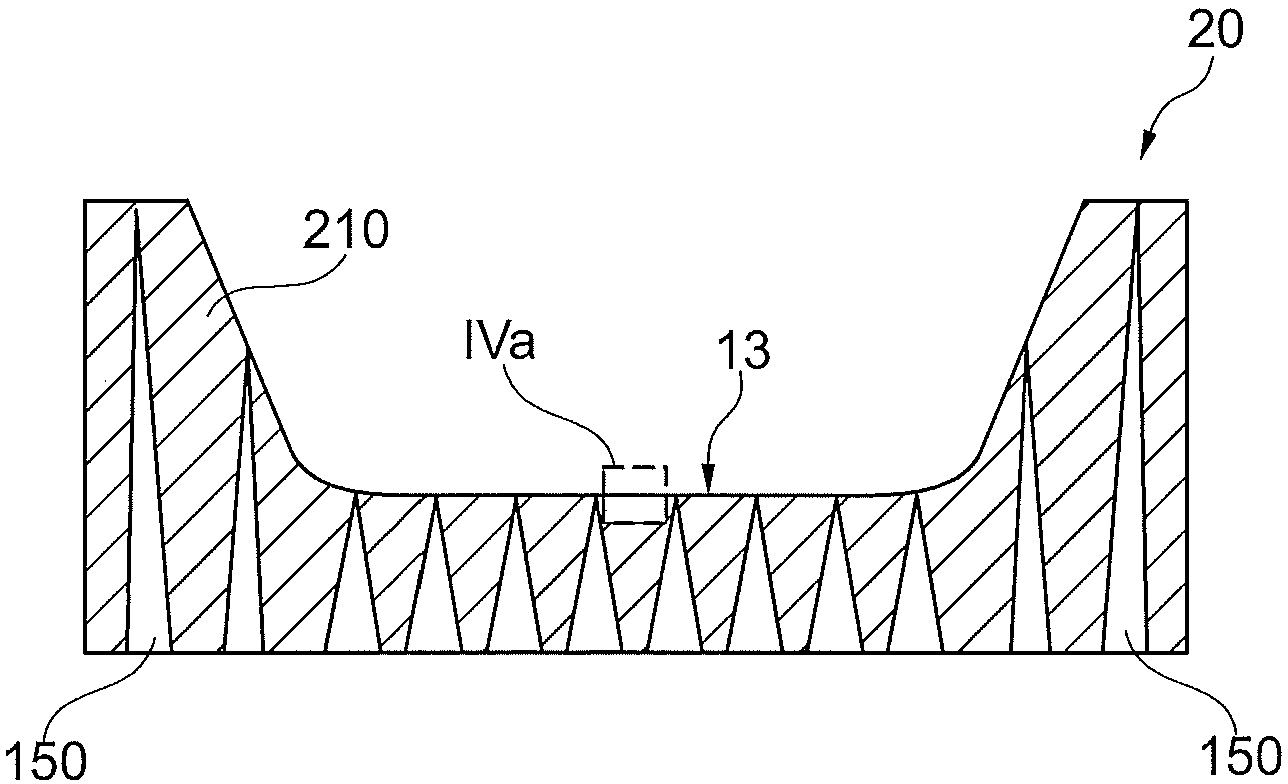

[0034] When the film is applied, the molded pulp product is supported in a perforated mold 10, 20, which has a complementary shape to the pulp product. In the text that follows, the male porous mold is numbered 10 and the female mold is numbered 20. The porous molds 10, 20 may be of the same kind used as pulp molds in the forming section 1 during forming and subsequent pressing. Examples of suitable female and male porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com