Active-control valley fill circuit and control method thereof

A valley-filling circuit and control circuit technology, which is applied to electrical components, high-efficiency power electronic conversion, and output power conversion devices, etc., can solve the problems of lower performance indicators, increased cost, and limited application of valley-filling circuits in the later stage switching power supply. , to achieve the effect of low circuit cost, improved power factor and simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

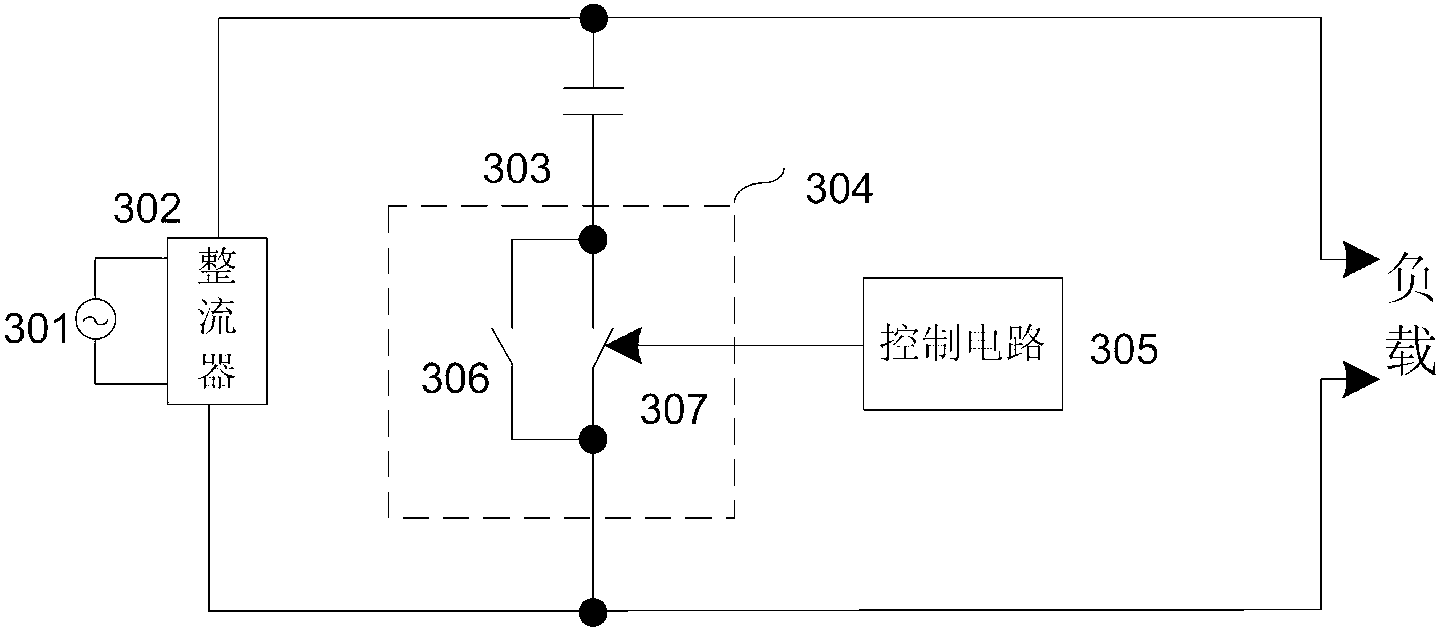

[0037] image 3 It is a basic schematic diagram of the active control valley filling circuit of the present invention, including an AC power supply 301, a rectifier 302, an energy storage capacitor 303, a switch circuit 304, a control circuit 305 and a load. in,

[0038] The alternating current 301 is connected to the input of the rectifier 302, the output of the rectifier 302 is connected to the load, the power terminal of the switch circuit 304 is connected in series with the energy storage capacitor 303 and then connected in parallel to both ends of the output of the rectifier 302, the control terminal of the switch circuit 304 is connected to the control circuit 305, The control circuit 305 is connected to the alternating current for detecting the voltage phase signal of the alternating current;

[0039] The switch circuit includes a char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com