Device and method for automatically detecting defects of glass medicine bottle

A technology of automatic detection device and medicine bottle, which is applied in the direction of measuring device, material analysis by optical means, instrument, etc., to achieve the effect of saving manpower, reducing enterprise cost and increasing labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

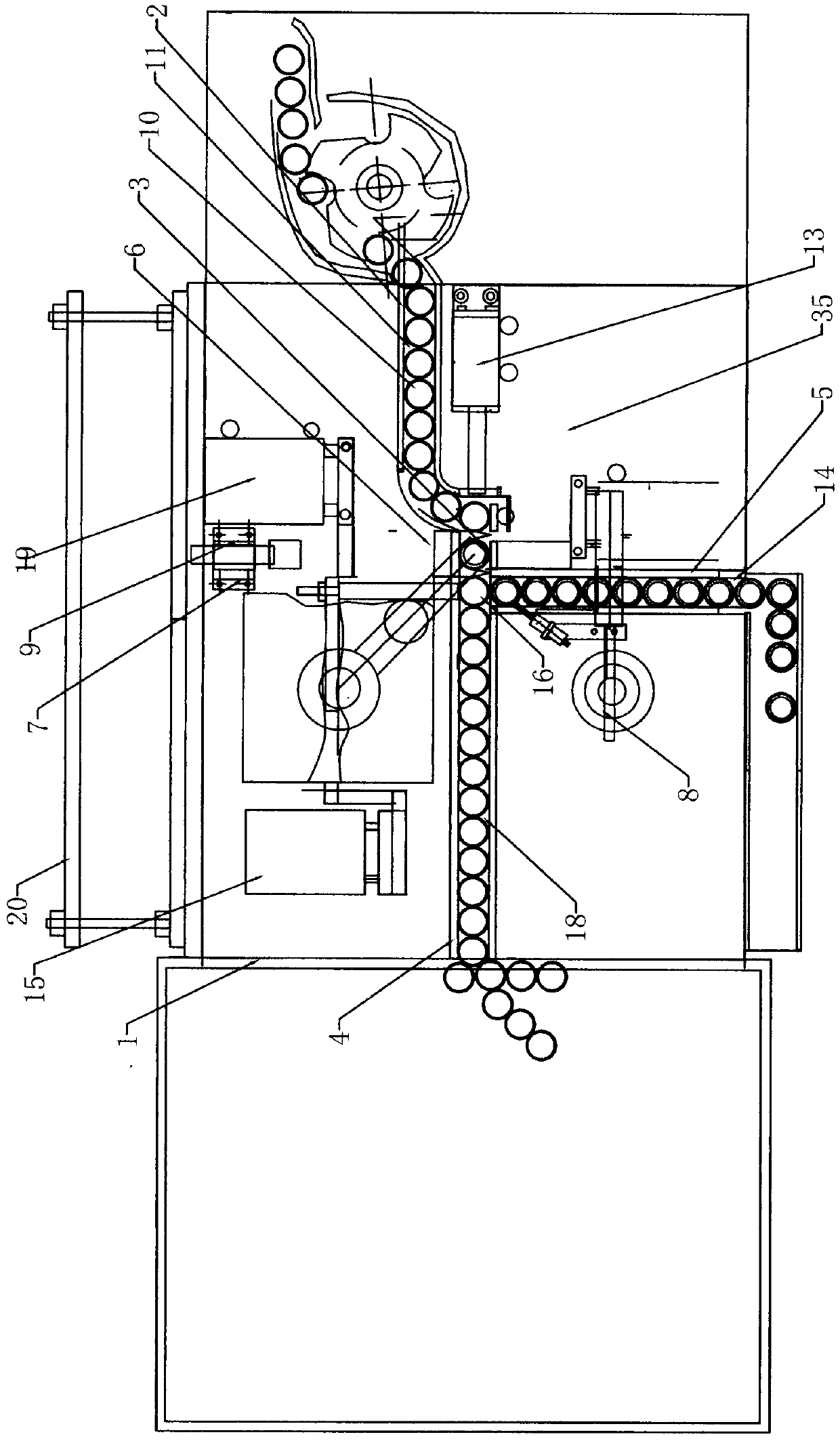

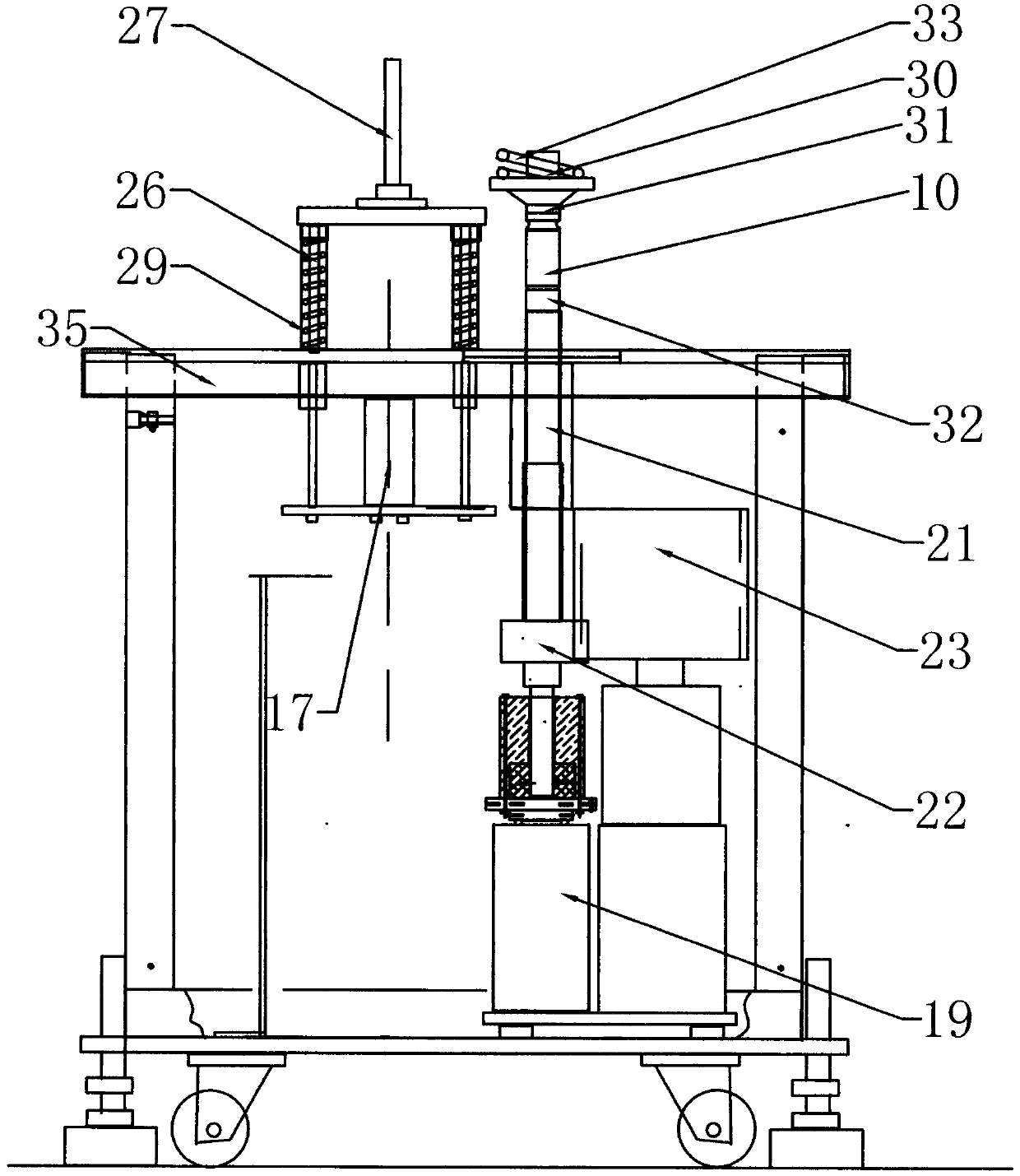

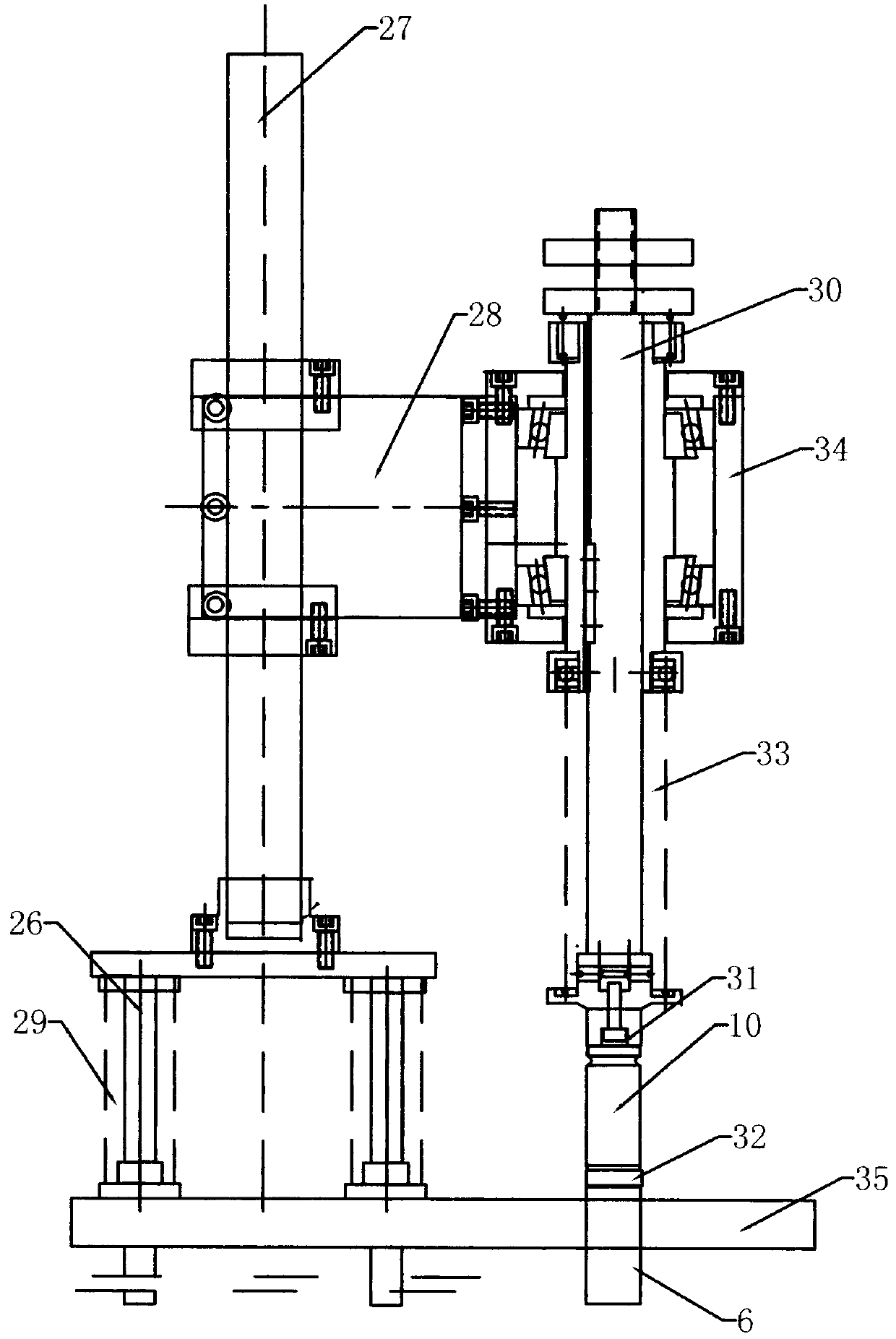

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail, a kind of automatic detection device of glass medicine bottle defect, comprises the frame 1 that is provided with table top 35 and the medicine bottle feeding mechanism 2 that is installed on the table top 35, detection station 3, Discharging mechanism 4, bad bottle rejecting mechanism 5, bottle lifting rotating mechanism 6 and visual inspection mechanism 7, see figure 1 shown. Wherein, the visual detection mechanism 7 is composed of a camera 9 installed beside the detection station 3, a light source 8 corresponding to the camera, a light baffle 20, and an industrial computer connected to the camera. The rising position of the bottle-lifting rotating mechanism 6 corresponds to the position of the camera 9, so that the medicine bottle 10 can be photographed and detected.

[0023] The above-mentioned medicine bottle feeding mechanism 2 is composed of a continuous medicine bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com