Clutch driven plate torque detection device

A torque detection and clutch technology, which is used in measuring devices, machine gear/transmission mechanism testing, instruments, etc., can solve the problems that the signal cannot be returned to zero, the detection accuracy is low, and the cost is high, achieving high accuracy, long service life and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

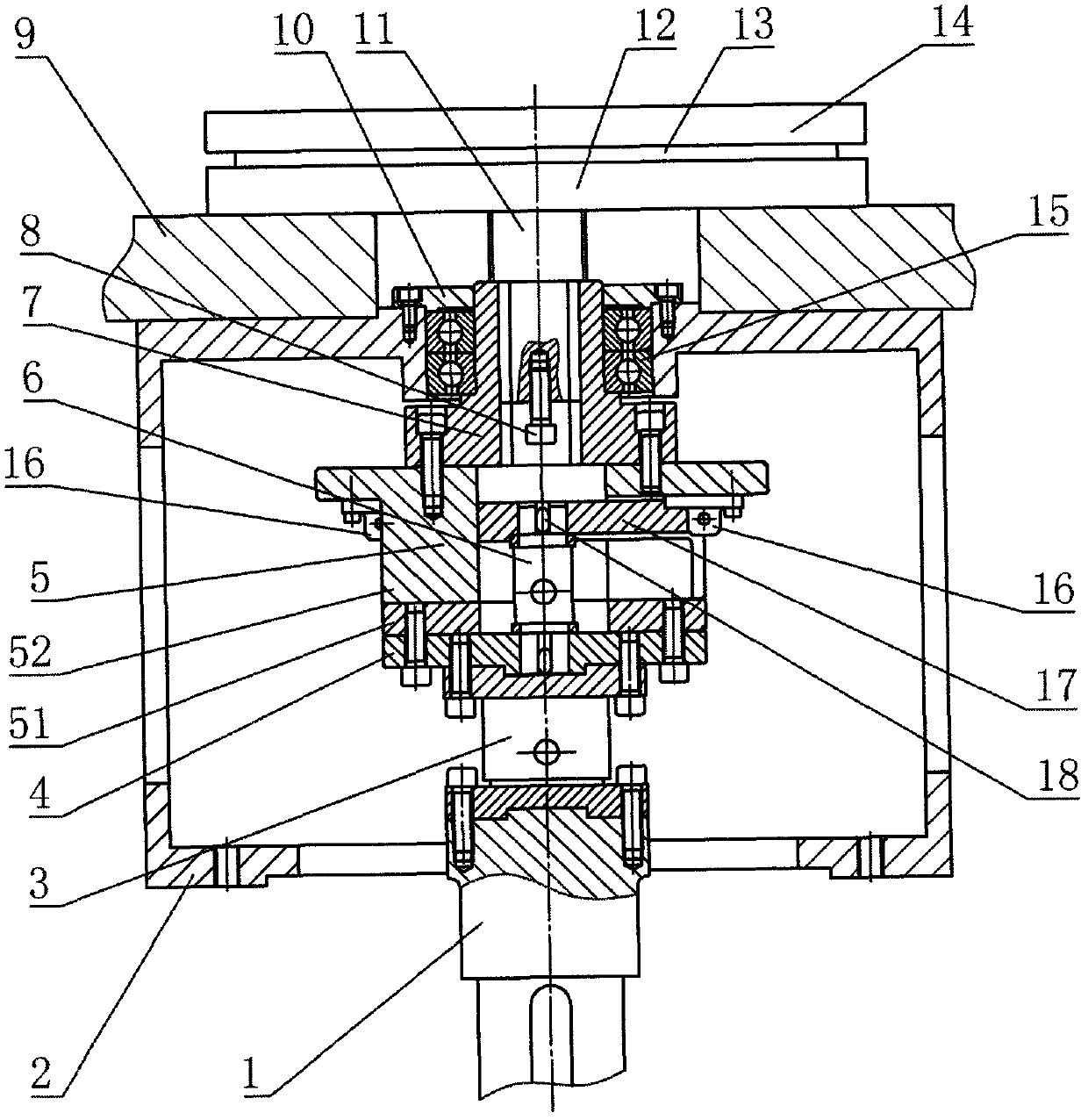

[0007] see figure 1 , the present invention includes an output shaft 1, a support sleeve 2, a table plate 9, a spline shaft 11, a lower tooling plate 12 and an upper tooling plate 14, and also includes a large-range static torque sensor 3, a connecting plate 4, and a star coupling 5. Small-range static torque sensor 6, connecting flange 7, adjusting screw 8, bearing cap 10, bearing 15, spring return seat 16 and swing rod 17, the large-range static torque sensor 3 passes through the flanges at both ends respectively Connect the output shaft 1 and the connection plate 4 with screws, the star coupling 5 includes a lower connector 51 and an upper connector 52, the connection plate 4 is connected with the star coupling 5 with screws, and the small-range static torque sensor The lower end of 6 is connected with the connecting plate 4 by a flat key, the upper end of the small-range static torque sensor 6 is connected with the swing rod 17 by a key 18, and the spring return seat 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com