Faucet valve core

A faucet and spool technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of aggravating the production cost of faucets, user use costs, waste of resources, etc., to achieve convenient implementation, reduce the use of materials, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

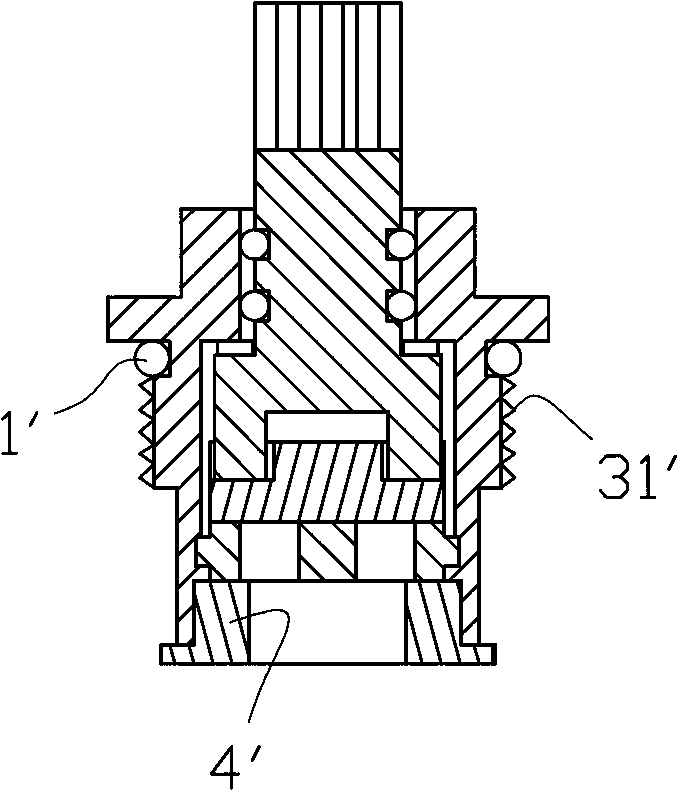

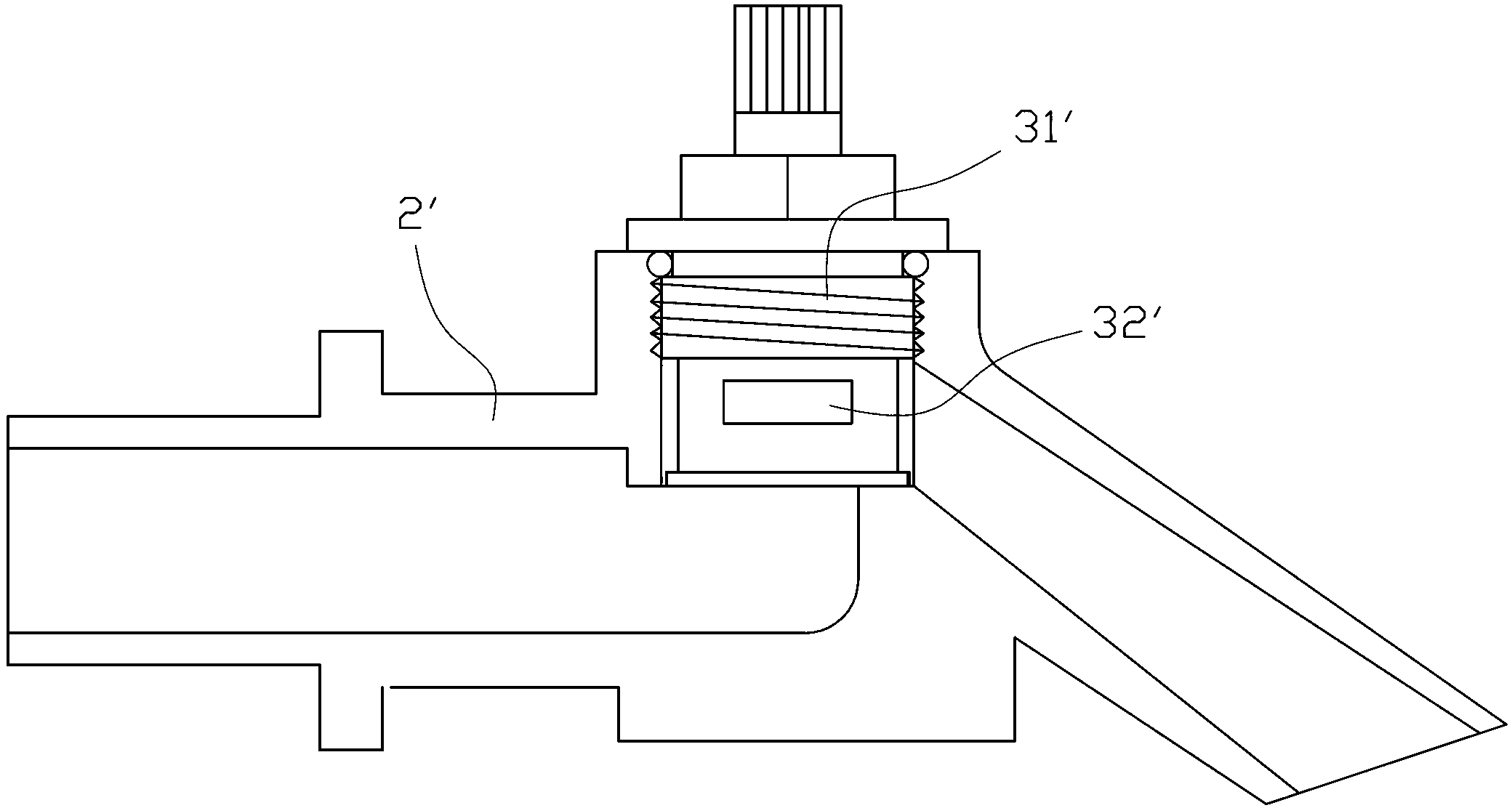

[0015] refer to Figure 4~Figure 6 , the faucet spool of the present invention includes a spool body 1, a rotating rod 2, a moving valve piece 3 and a fixed valve piece 4 installed in the spool body 1 sequentially from top to bottom, and the moving valve piece 3 is fixed At the bottom of the rotating rod 2, the movable valve plate 3 can follow the rotation of the rotating rod 2 to open or close the water inlet and outlet on the fixed valve plate 4. One side acts on the fixed valve plate 4, and the other side acts on the bottom of the valve core installation position of the faucet main body 7, thereby playing the role of sealing and closing the water. The side wall of the valve core body 1 is provided with a mounting thread part 11 and an outlet The nozzle 12 and the mounting thread part 11 are used to install the valve core in the valve core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com