Combined support device of magnetic bearing rotor system

A magnetic levitation bearing and support device technology, applied to bearings, shafts and bearings, mechanical equipment, etc., to achieve the effect of suppressing vibration and good damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A combined support device for a magnetic suspension bearing rotor system, comprising a machine base, a rotor assembly and a magnetic suspension bearing assembly, the rotor assembly is supported by the magnetic suspension bearing assembly, the magnetic suspension bearing assembly is supported by a squirrel-cage elastic support device, and the squirrel-cage elastic support device is composed of a machine Seat support, a metal rubber ring is also arranged between the squirrel-cage elastic support device and the machine base.

Embodiment 2

[0037] On the basis of embodiment 1, the preferred technical scheme of the present invention is:

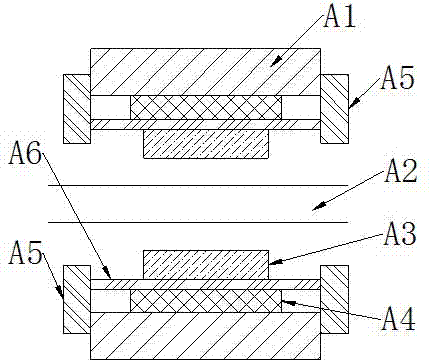

[0038] Such as figure 1 , a combined support device for a magnetic suspension bearing rotor system, comprising a machine base A1, a rotor assembly A2 and a magnetic suspension bearing assembly A3, the rotor assembly A2 is supported by the magnetic suspension bearing assembly A3, the magnetic suspension bearing assembly A3 is supported by a squirrel-cage elastic support device, and the squirrel cage The cage-type elastic support device is supported by the base A1, and a metal rubber ring A4 is also arranged between the squirrel-cage elastic support device and the base A1. The squirrel-cage elastic supporting device includes two end rings A5 and several cage bars A6, the two end rings A5 are respectively directly or indirectly fixed to the base A1, and each cage bar A6 is directly or indirectly fixed to the magnetic suspension bearing assembly A3.

Embodiment 3

[0040] On the basis of embodiment 1, the preferred technical scheme of the present invention is:

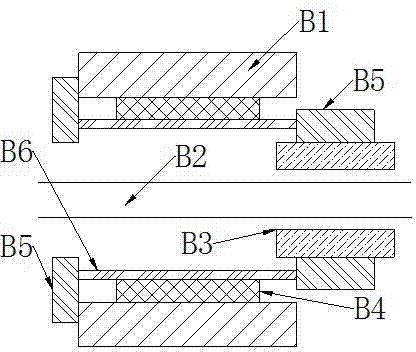

[0041] Such as figure 2 , a combined support device for a magnetic suspension bearing rotor system, comprising a base B1, a rotor assembly B2 and a magnetic suspension bearing assembly B3, the rotor assembly B2 is supported by a magnetic suspension bearing assembly B3, and the magnetic suspension bearing assembly B3 is supported by a squirrel-cage elastic support device, the squirrel cage The cage type elastic supporting device is supported by the machine base B1, and a metal rubber ring B4 is also arranged between the squirrel cage type elastic supporting device and the machine base B1. The squirrel-cage elastic support device includes two end rings B5 and several cage bars B6, one end ring B5 is directly or indirectly fixed to the base B1, and the other end ring B5 is directly or indirectly fixed to the magnetic suspension bearing assembly B3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com