An underground hydraulic oil pumping system

A power system and hydraulic power technology, which is applied in the field of downhole rodless hydraulic power pumping system to achieve the effects of improving system efficiency, overcoming friction and energy loss, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

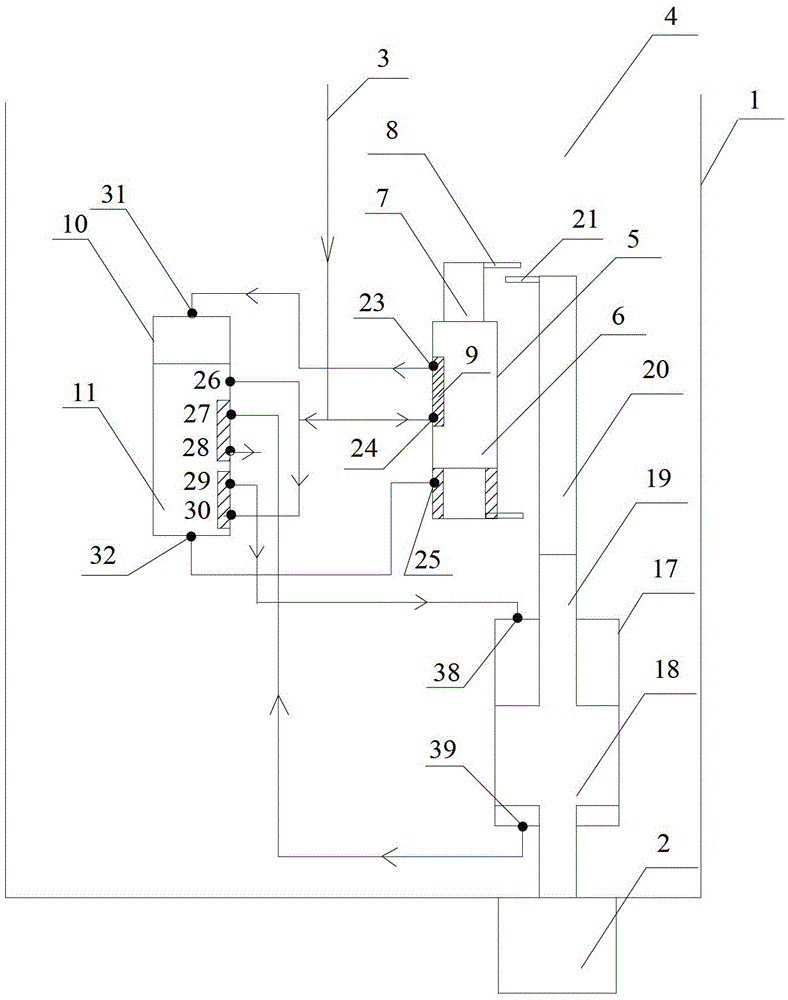

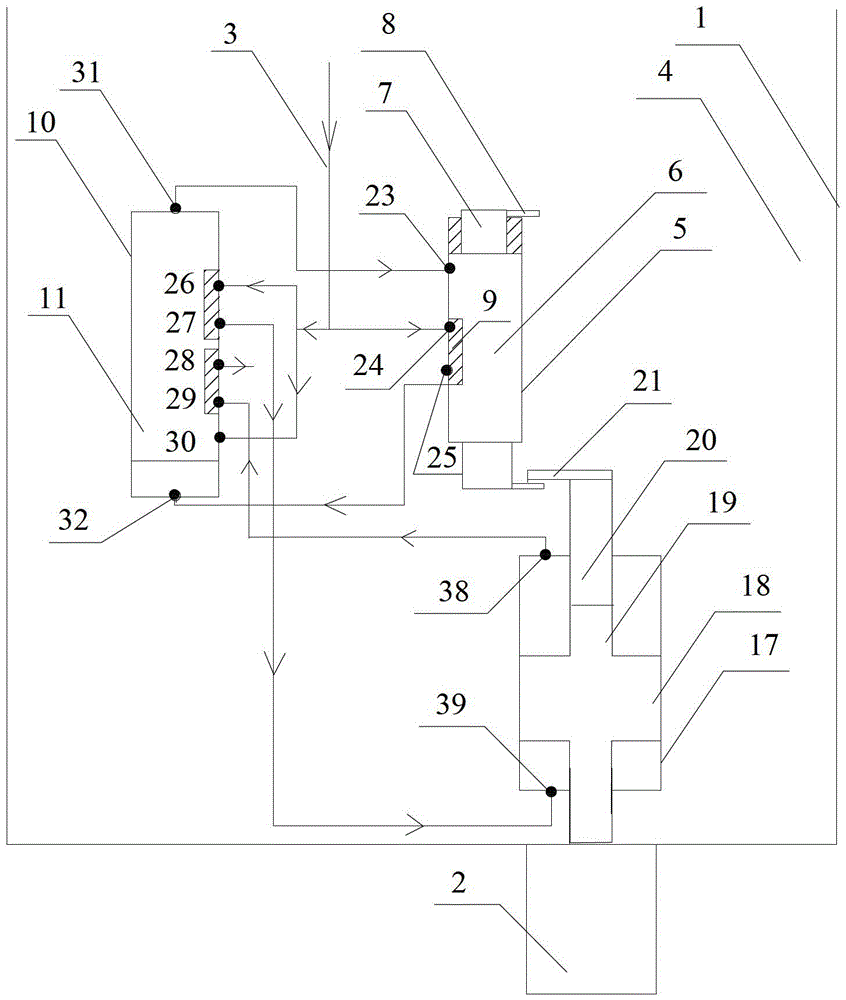

[0042]A downhole hydraulic power pumping system, including a power system, a command system and a steering system arranged in a tubing 1, the power system is connected to an oil well pump 2, and the tubing 1 has a power fluid channel 3 and a channel 4 for mixing the idle power fluid and the well fluid , the power system, command system and steering system are all structures with pistons in the cylinder;

[0043] The command system is a cylindrical cylinder, which is called the command cylinder 5, and the inside is provided with a piston that can slide up and down, called the command piston 6. The length of the command piston 6 is less than the length of the command cylinder 5, and the two ends of the command cylinder 5 Open, the two ends of the command piston 6 are respectively provided with a bump 7 with a cross-sectional area smaller than the cross-sectional area of the command cylinder 5, and a hanging block 8 is respectively arranged on the bump 7, and a concave block 9 i...

Embodiment 2

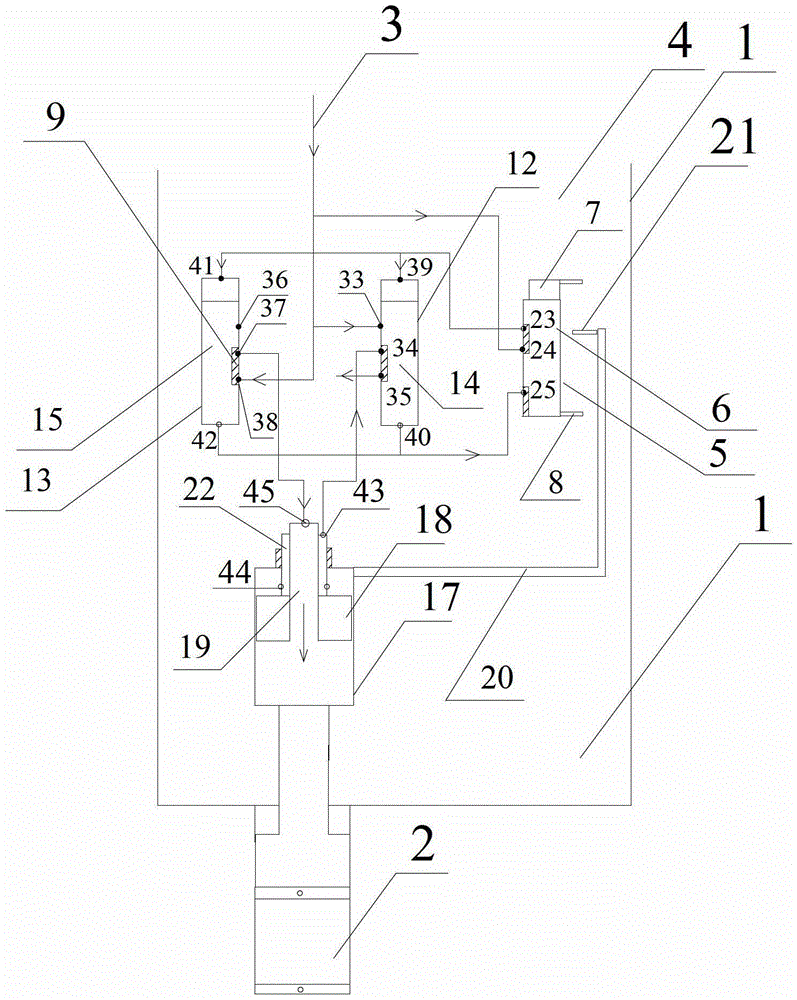

[0052] The difference from Embodiment 1 lies in the changes of the steering system and the power system, specifically:

[0053] The steering structure is two cylindrical cylinders, which are denoted as the first steering cylinder 12 and the second steering cylinder 13. The two steering cylinders are provided with pistons that can slide up and down, which are correspondingly denoted as the first steering cylinder. Steering piston 14 and the second steering piston 15, the length of the first steering piston 14 is 5 / 6 of the first steering cylinder 12, a concave block 9 is arranged in the middle of the first steering piston 14, and the On the cylinder block 12, from top to bottom, 1 / 3, 1 / 2, and 2 / 3 are provided with holes, which are denoted as the eleventh hole 33, the twelfth hole 34, and the thirteenth hole 35; Two steering cylinders 13 and the second steering piston 15 are identically arranged, and the holes on it are marked as the fourteenth hole 36, the fifteenth hole 37, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com