Full-pneumatic accident driving system for metallurgical production equipment

A technology for production equipment and drive systems, applied in mechanical equipment, pneumatic program control, machine/engine, etc., can solve the problem of no control of action correlation, can not meet, increase equipment operating conditions and costs, etc., to avoid human operation. Mistakes or Unreasonable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

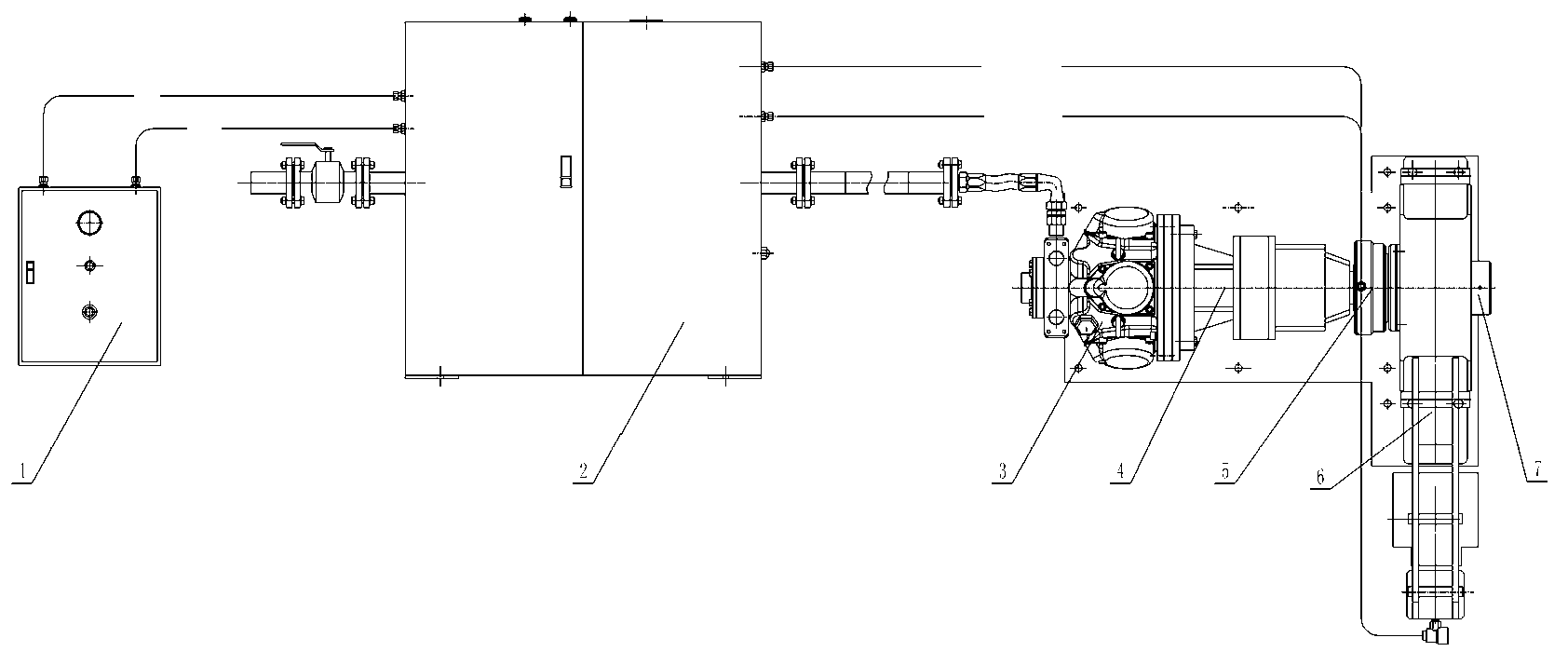

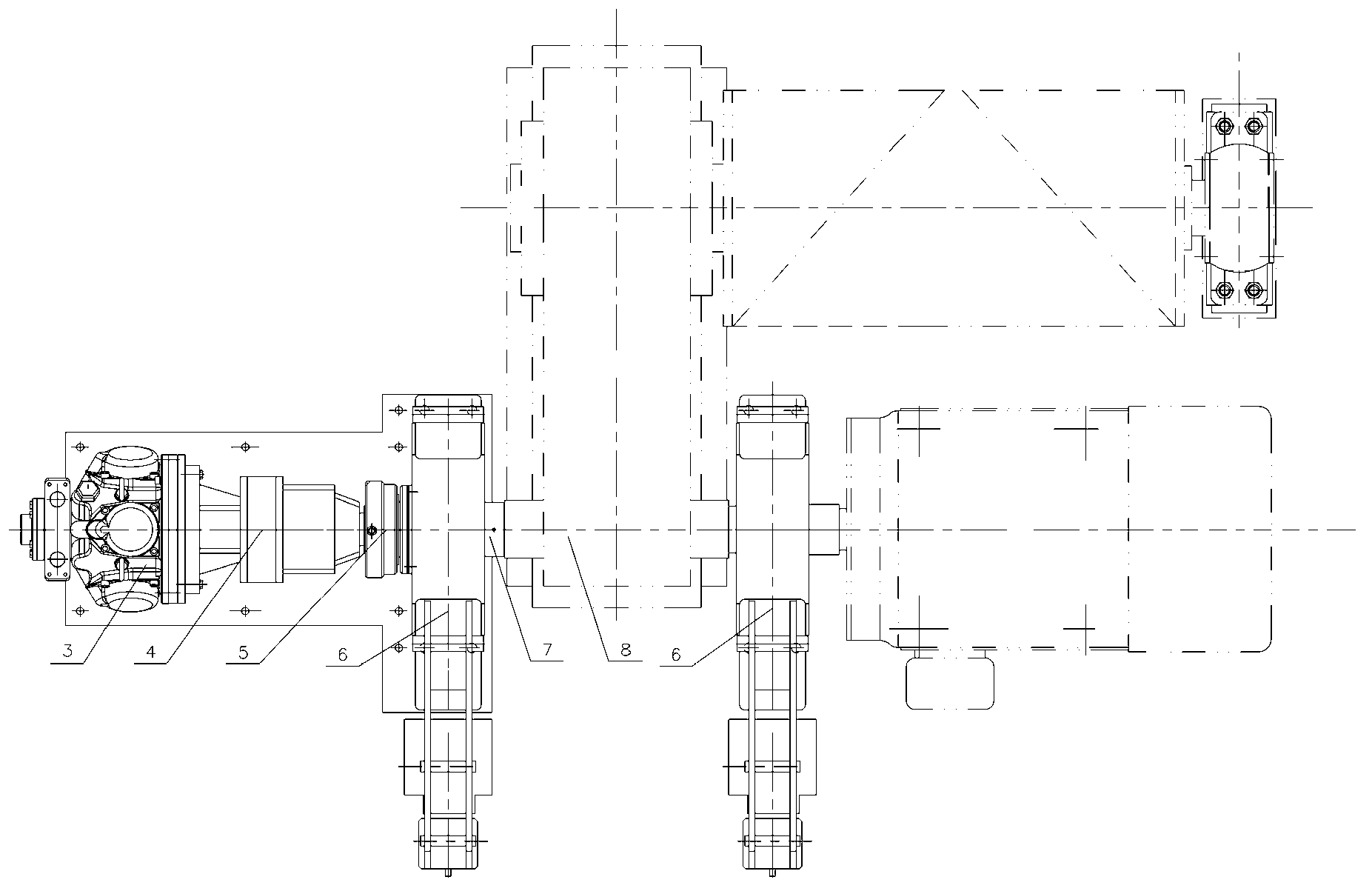

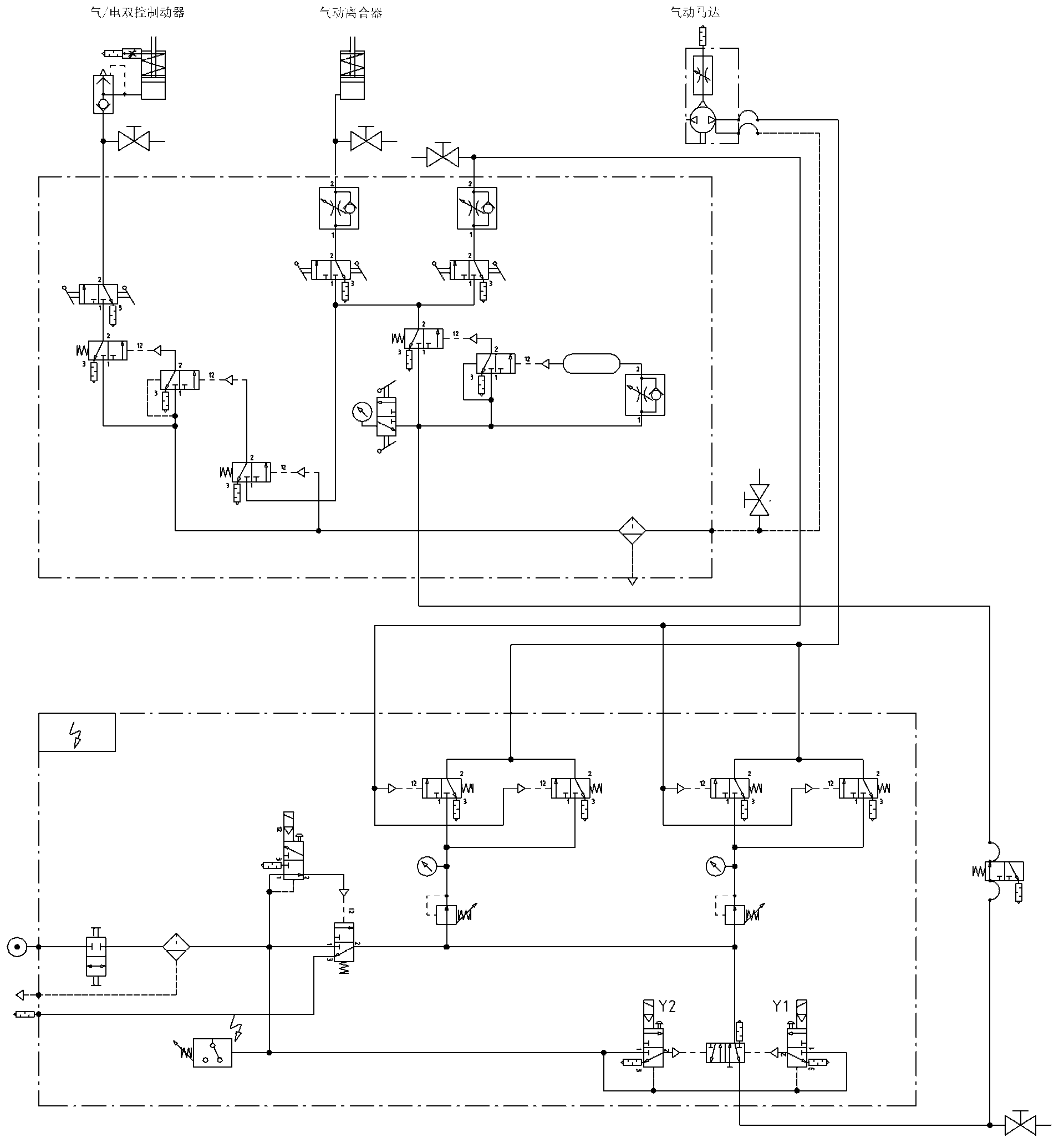

[0019] The full pneumatic accident drive system in the metallurgical production equipment of the present invention includes a pneumatic control cabinet, a power output mechanism connected to the pneumatic control cabinet and a power transmission mechanism connected to the power output end of the power output mechanism, wherein the control cabinet controls The execution sequence of each device of the power transmission mechanism, the power output device is an air motor.

[0020] Such as Figures 1 to 6 As shown, the full pneumatic accident drive system in the metallurgical production equipment of this embodiment includes a pneumatic control cabinet, a power output mechanism connected to the pneumatic control cabinet and a power transmission mechanism connected to the power output end of the power output mechanism, wherein the The control cabinet controls the execution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com