Detergent pouring controller

A detergent injection and controller technology, which is applied to washing devices, tableware washing machines/rinsing and washing machine parts, and other washing machines, etc., can solve problems such as inaccurate injection accuracy, complex structure, and blocked equipment operation, and achieve compact structure , simple structure and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

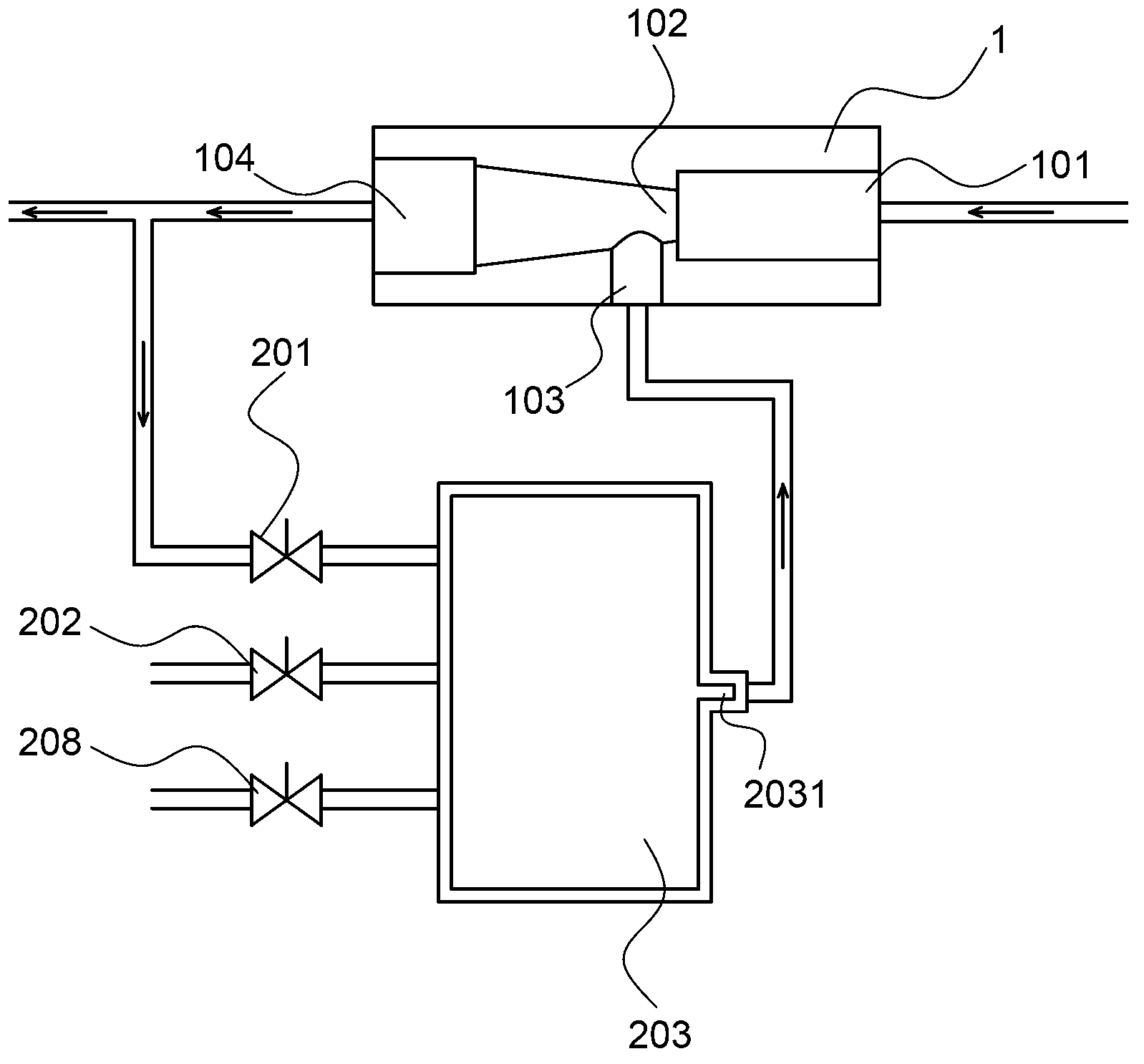

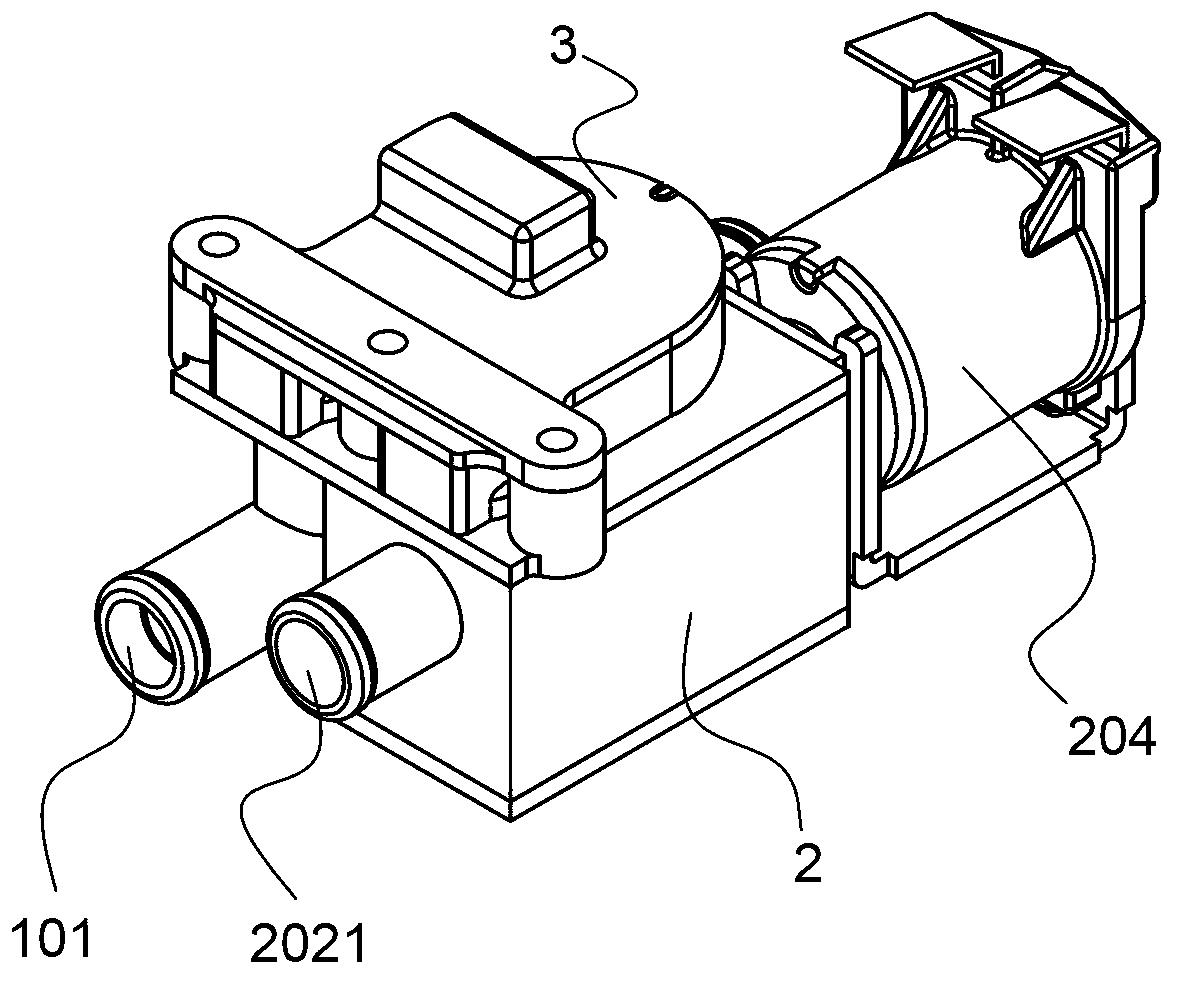

[0032]The detergent injection controller is provided with a valve body 2, the valve body has a valve cavity 203, the valve cavity has a valve cavity outlet 2031, the valve body is provided with a valve A201 and a valve B202, and the valve A and the valve B are opened. The outlet of the valve A and The outlet of valve B passes through the valve cavity 203; the valve body is connected with a negative pressure generator 1, which has an inlet 101 connected to the water source and an outlet 104 connected to the water inlet pipe of the washing tub. There is a zoom port 102 connected, the small port of the zoom port corresponds to the inlet, the large port of the zoom port corresponds to the outlet, the side of the zoom port is connected with a negative pressure port 103, and the outlet of the negative pressure generator is connected with the inlet 2011 of valve A, The negative pressure port of the negative pressure generator is in communication with the outlet of the valve chamber, a...

Embodiment 2

[0034] In this example, a valve C is provided in the valve body described in Example 1. When the valve C is open, the outlet of the valve C passes through the valve chamber, and the valve C has an inlet connected to the detergent B liquid storage tank. Other structures are the same as in Example 1.

Embodiment 3

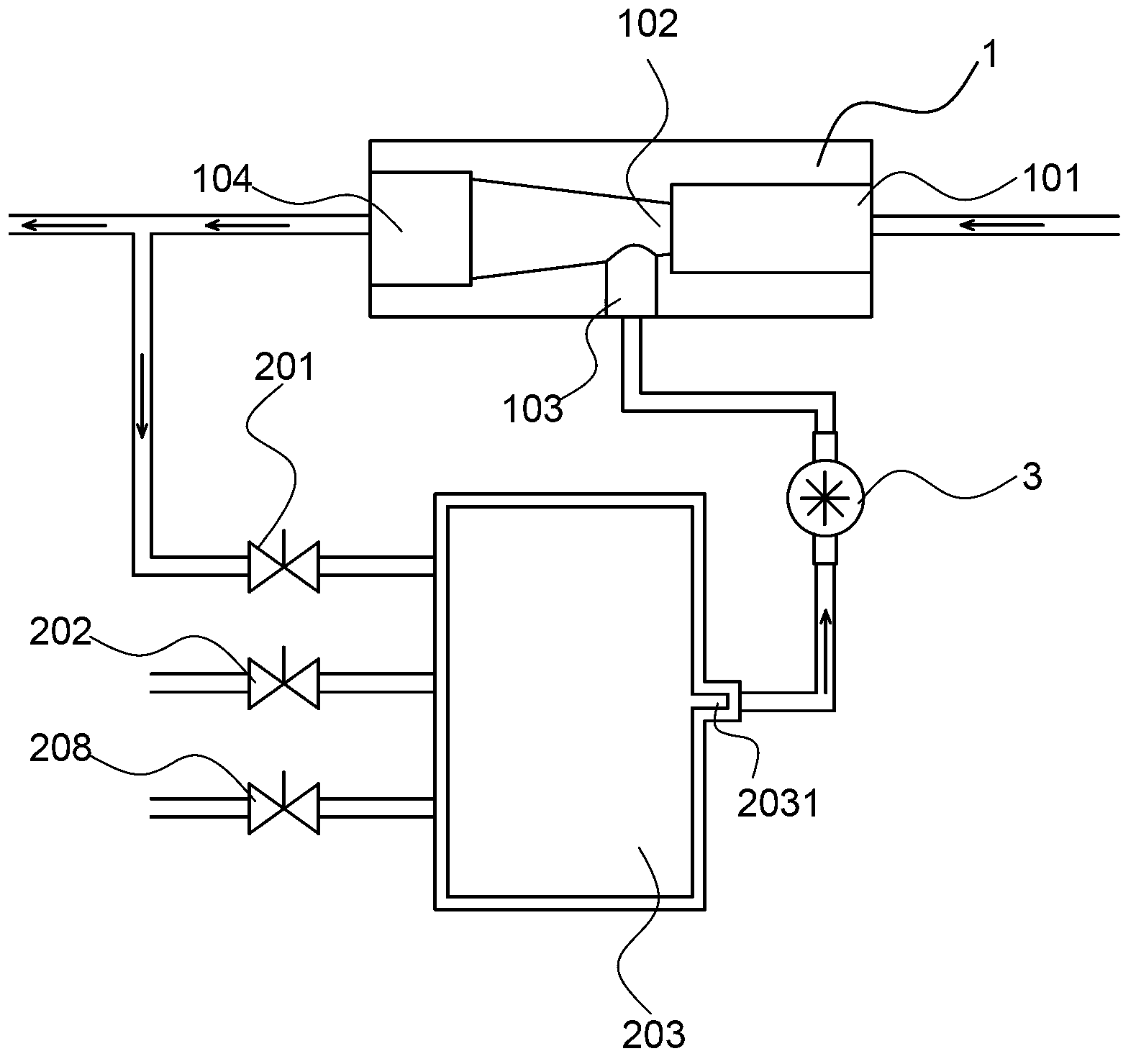

[0036] In this example, a bonnet 207 is connected to the valve cavity described in Example 1, and a negative pressure port 2072 and a communication port 2071 are provided on the bonnet, and the negative pressure port and the negative pressure port of the negative pressure generator Connected, the communication port communicates with the outlet of the valve cavity, and a flow sensor 3 is connected between the communication port and the negative pressure port. Other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com