A kind of oil-based metal cutting fluid and preparation method thereof

A metal-based and cutting fluid technology, which is applied in the field of oil-based metal cutting fluid and its preparation, can solve the problems of difficult use and maintenance of cutting fluid, difficult disposal of waste liquid, and high cost of waste liquid treatment, achieving strong promotion and application value, It is convenient for large-scale production and the effect of low waste liquid treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

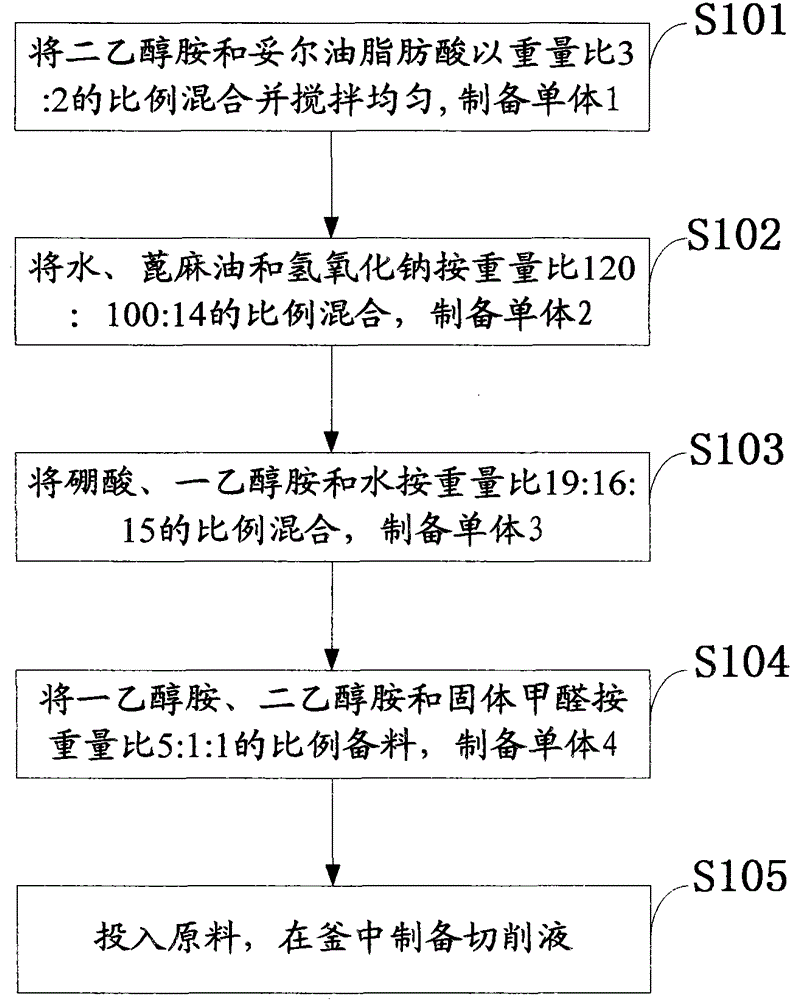

[0031] The preparation method includes the following steps:

[0032] S101: Preparation of Monomer 1: Mix diethanolamine and tall oil fatty acid in a weight ratio of 3:2 and stir evenly, heat up to 120-130°C, maintain for 60 minutes, and use it for later use;

[0033] S102: Preparation of monomer 2: mix water, castor oil and sodium hydroxide in a weight ratio of 120:100:14, and proceed as follows: add water to the kettle, slowly add sodium hydroxide and stir evenly , Raise the temperature to 90-95°C, slowly add monoethanolamine after 20-30 minutes, stir to make it evenly mixed, and raise the temperature to 90-95°C again, maintain it for 30-60 minutes, for use;

[0034] S103: Preparation of monomer 3: mix boric acid, monoethanolamine and water in a ratio of 19:16:15 by weight, and stir well for use;

[0035] S104: Preparation of monomer 4: prepare monoethanolamine, diethanolamine and solid formaldehyde in a weight ratio of 5:1:1, put monoethanolamine and diethanolamine into the kettle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com