Sequencing-batch polluted soil remediation method and device

A kind of polluted soil, sequencing batch technology, applied in the field of electrochemical repair, can solve the problems of complex process flow, complex device structure, high device cost, etc., and achieve the effect of good permeability, easy installation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings.

[0026] Sequencing batch repairing device includes electrochemical repairing tank 1, tubular mixer 2, repairing electrode 3, card slot 4, cathode zone control valve 5, anode zone control valve 6 and perforated pipe 7. The electrochemical repair cell 1 is provided with evenly spaced card slots 4 on both sides of the cell wall, and the repair electrode 3 is fixedly installed in the electrochemical repair cell 1 through the card slots 4, one side is the anode area and the other side is the cathode area. The tubular mixer 2 is connected to the perforated pipe 7, which is evenly distributed between the repair electrodes 3 spaced apart.

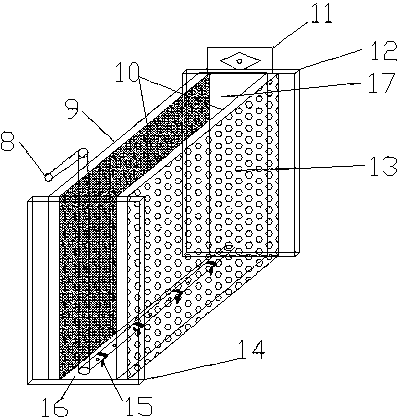

[0027] The repair electrode 3 includes an oxidant dosing tube 8, a porous electrode 9, a filter membrane 10, a power connection port 11, a splint 12, a porous electrode 13, a splint 14, a pipe clamp 15, a bottom plate 16 and an electrode cavity 17. The porou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com